Soap curing allows excess water to evaporate, resulting in a harder, longer-lasting bar that produces a creamier lather and is gentler on a pet's skin. Immediate use soap may be softer and less durable, potentially causing irritation or faster wear when used on pets. Properly cured soap enhances cleanliness and comfort during pet grooming by maintaining optimal pH and moisture balance.

Table of Comparison

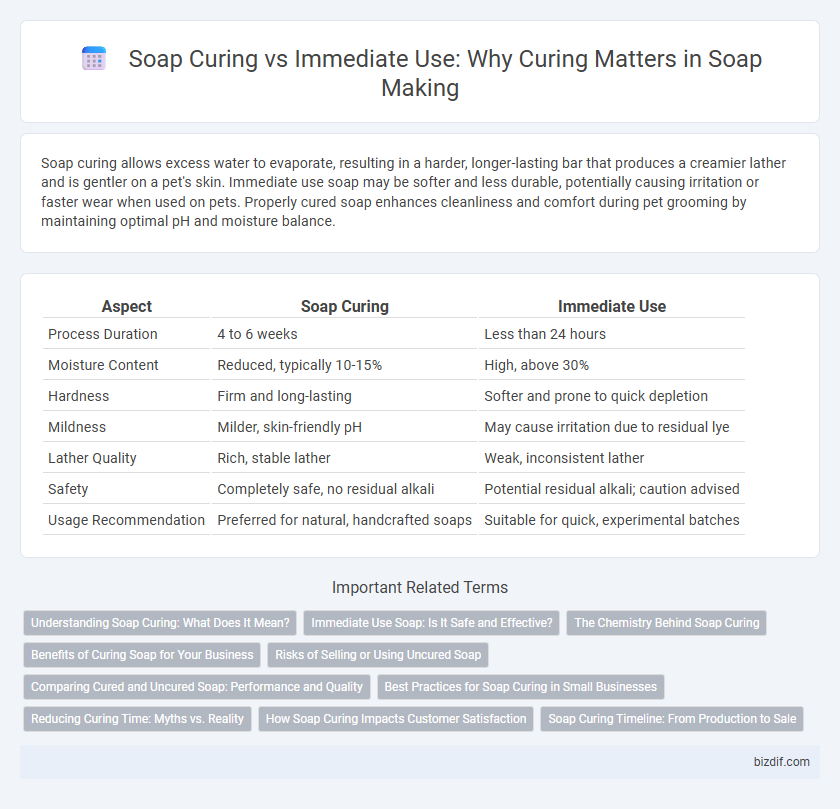

| Aspect | Soap Curing | Immediate Use |

|---|---|---|

| Process Duration | 4 to 6 weeks | Less than 24 hours |

| Moisture Content | Reduced, typically 10-15% | High, above 30% |

| Hardness | Firm and long-lasting | Softer and prone to quick depletion |

| Mildness | Milder, skin-friendly pH | May cause irritation due to residual lye |

| Lather Quality | Rich, stable lather | Weak, inconsistent lather |

| Safety | Completely safe, no residual alkali | Potential residual alkali; caution advised |

| Usage Recommendation | Preferred for natural, handcrafted soaps | Suitable for quick, experimental batches |

Understanding Soap Curing: What Does It Mean?

Soap curing is the process of allowing freshly made soap to rest and dry for several weeks, typically 4 to 6, to ensure excess water evaporates and the soap hardens. This period enables saponification to complete fully, improving the soap's texture, longevity, and mildness on the skin. Using soap immediately may result in a softer bar that dissolves quickly and can irritate the skin due to incomplete curing.

Immediate Use Soap: Is It Safe and Effective?

Immediate use soap may not have undergone the full curing process, leaving higher moisture content that can reduce hardness and shorten shelf life. While it is generally safe if properly formulated, uncured soap might be softer and less effective at cleansing compared to fully cured bars. Ensuring proper pH levels and avoiding harsh ingredients are crucial for maintaining safety and effectiveness in immediate use soap.

The Chemistry Behind Soap Curing

Soap curing involves a chemical process called saponification, where triglycerides react with lye to form soap and glycerin, allowing the soap to harden and become milder over time. During curing, excess water evaporates, which enhances the soap's durability and creates a better lather by stabilizing its molecular structure. Immediate use soap lacks this curing phase, resulting in a softer texture and higher alkalinity that can be harsh on the skin.

Benefits of Curing Soap for Your Business

Curing soap enhances its hardness, longevity, and lather quality, resulting in a superior product that attracts more customers and fosters repeat sales. Proper curing reduces excess moisture, preventing early disintegration and extending shelf life, which minimizes returns and increases profitability. Investing time in curing supports brand reputation by delivering consistent, high-quality bars that stand out in competitive markets.

Risks of Selling or Using Uncured Soap

Selling or using uncured soap poses significant risks such as skin irritation, pH imbalance, and incomplete saponification, which can result in harsh, caustic products harmful to users. Uncured soap retains excess moisture causing it to be soft and prone to faster bacterial growth, leading to potential health hazards and reduced shelf life. Proper curing, typically 4-6 weeks, ensures hardness, milder pH, and safety by allowing water evaporation and thorough chemical reaction completion.

Comparing Cured and Uncured Soap: Performance and Quality

Cured soap typically exhibits superior hardness, longer-lasting lather, and gentler cleansing properties due to the complete saponification and moisture evaporation during the curing process. Uncured soap often has a softer texture, may retain excess alkali, and produce a less stable lather, leading to quicker deterioration and potential skin irritation. Performance and quality measures heavily favor cured soap for durability, mildness, and overall user satisfaction in soap making.

Best Practices for Soap Curing in Small Businesses

Optimal soap curing in small businesses involves maintaining a controlled environment with temperatures between 60-80degF and humidity levels around 50-60% to ensure proper hardening and moisture evaporation. Allowing soap to cure for 4 to 6 weeks enhances lather quality, longevity, and mildness by completing the saponification process and reducing excess water content. Regularly rotating soap batches and using breathable storage, such as wooden racks, supports even curing and prevents mold or sweat spots.

Reducing Curing Time: Myths vs. Reality

Reducing soap curing time is often misunderstood; while curing allows excess water to evaporate and ensures hardness, cutting curing short can result in a softer bar prone to quicker wear and less effective cleansing. Myths suggest additives or microwaving can replace traditional curing, but these methods typically compromise soap quality and longevity. Proper curing, usually 4-6 weeks, remains essential for optimal pH balance and durability in cold process soap making.

How Soap Curing Impacts Customer Satisfaction

Soap curing enhances customer satisfaction by improving the soap's hardness, longevity, and lather quality, resulting in a more enjoyable and durable product. Proper curing allows excess water to evaporate, preventing softness and extending shelf life, which meets customers' expectations for effective and reliable soap. Customers experience less residue and skin irritation from fully cured soap, increasing their trust and preference for the brand.

Soap Curing Timeline: From Production to Sale

Soap curing is a critical phase that spans typically 4 to 6 weeks, during which excess water evaporates and the soap hardens, enhancing lather quality and longevity. Immediate use soap lacks this curing period, leading to a softer texture that dissolves faster and may irritate the skin due to incomplete saponification. Understanding the soap curing timeline ensures optimal product stability, safety, and customer satisfaction before the soap reaches the market.

Soap Curing vs Immediate Use Infographic

bizdif.com

bizdif.com