Traditional molds in soap making pet provide consistent shapes and are typically made from durable materials like silicone or metal, ensuring repeatability and ease of use. Custom molds offer unique designs tailored to specific themes or branding, allowing pet product makers to create personalized, eye-catching soaps that stand out in the market. Choosing between traditional and custom molds depends on production scale, design complexity, and brand differentiation goals in pet soap crafting.

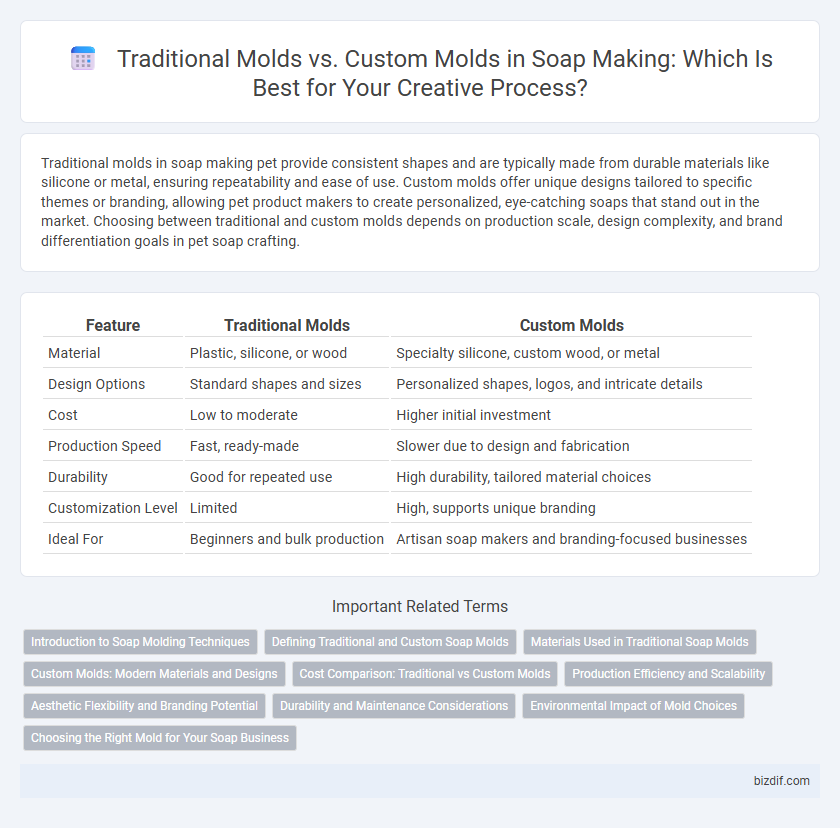

Table of Comparison

| Feature | Traditional Molds | Custom Molds |

|---|---|---|

| Material | Plastic, silicone, or wood | Specialty silicone, custom wood, or metal |

| Design Options | Standard shapes and sizes | Personalized shapes, logos, and intricate details |

| Cost | Low to moderate | Higher initial investment |

| Production Speed | Fast, ready-made | Slower due to design and fabrication |

| Durability | Good for repeated use | High durability, tailored material choices |

| Customization Level | Limited | High, supports unique branding |

| Ideal For | Beginners and bulk production | Artisan soap makers and branding-focused businesses |

Introduction to Soap Molding Techniques

Traditional molds for soap making often involve simple materials like wood, silicone, or plastic, providing consistent shapes and easy reuse. Custom molds enable artisans to create unique designs, intricate details, and personalized soap bars using 3D printed or handcrafted molds. Understanding the advantages of both techniques helps soap makers achieve desired aesthetics, texture, and production efficiency.

Defining Traditional and Custom Soap Molds

Traditional soap molds are typically made from wood, silicone, or metal, providing standard shapes like bars or blocks commonly used in classic soap making. Custom soap molds are designed to create unique, personalized shapes and sizes, often crafted from flexible silicone to accommodate intricate details and artistic designs. Both types serve different purposes, with traditional molds favoring simplicity and ease, while custom molds enable creativity and brand differentiation in soap products.

Materials Used in Traditional Soap Molds

Traditional soap molds are commonly made from materials such as wood, metal, and silicone, each offering unique benefits for soap curing and shaping. Wooden molds provide durability and a natural aesthetic, while metal molds, often aluminum or stainless steel, ensure even heat distribution during the saponification process. Silicone molds allow for flexibility and easy soap removal, making them popular in both artisanal and small-scale soap making.

Custom Molds: Modern Materials and Designs

Custom molds for soap making leverage modern materials such as silicone and flexible plastics, offering enhanced durability and ease of release compared to traditional wooden or metal molds. These molds enable intricate, personalized designs that cater to unique branding and aesthetic preferences, elevating the overall product appeal. Advanced 3D printing technology further expands customization possibilities, allowing soap makers to create complex shapes and patterns with precision.

Cost Comparison: Traditional vs Custom Molds

Traditional soap molds typically cost less upfront due to mass production and standard sizes, making them ideal for large-scale, consistent batches. Custom molds involve higher initial expenses because of design complexity and material costs but offer flexibility for unique shapes and branding opportunities. Evaluating long-term production needs helps determine whether lower initial costs or tailored designs provide better overall value.

Production Efficiency and Scalability

Traditional soap molds offer consistent shapes and sizes, streamlining production with minimal setup time, ideal for small to medium batches. Custom molds enhance scalability by enabling unique designs and varied product lines, but often require longer preparation and curing times. Balancing mold selection directly impacts production efficiency and the ability to scale operations in soap making.

Aesthetic Flexibility and Branding Potential

Traditional molds provide consistent shapes and textures that evoke classic appeal but limit creative design variation. Custom molds enable unique forms and intricate details tailored to brand identity, enhancing product differentiation and market recognition. Investing in custom molds elevates aesthetic flexibility, allowing soap makers to align visual style with specific branding strategies effectively.

Durability and Maintenance Considerations

Traditional soap molds are typically made from wood or metal, offering robust durability but requiring regular cleaning and occasional resealing to prevent moisture damage and warping. Custom molds, often crafted from silicone or specialized plastics, provide excellent flexibility and resistance to sticking while demanding minimal maintenance due to their non-porous surfaces. Choosing between traditional and custom molds depends on balancing long-term durability with ease of cleaning and upkeep in soap making.

Environmental Impact of Mold Choices

Traditional molds often use natural materials like wood or silicone, which can be biodegradable or recyclable, reducing waste in soap making. Custom molds, made from plastic or synthetic materials, may have a higher environmental footprint due to production processes and limited recyclability. Choosing eco-friendly molds supports sustainable soap production by minimizing resource consumption and landfill contributions.

Choosing the Right Mold for Your Soap Business

Traditional soap molds offer durability and ease of use, making them ideal for startups and small-scale soap businesses seeking consistent shapes and sizes. Custom molds provide unique designs that help brands stand out and appeal to niche markets, enhancing product differentiation and customer loyalty. Selecting the right mold depends on production volume, design complexity, and target audience preferences to optimize efficiency and brand identity.

Traditional Molds vs Custom Molds Infographic

bizdif.com

bizdif.com