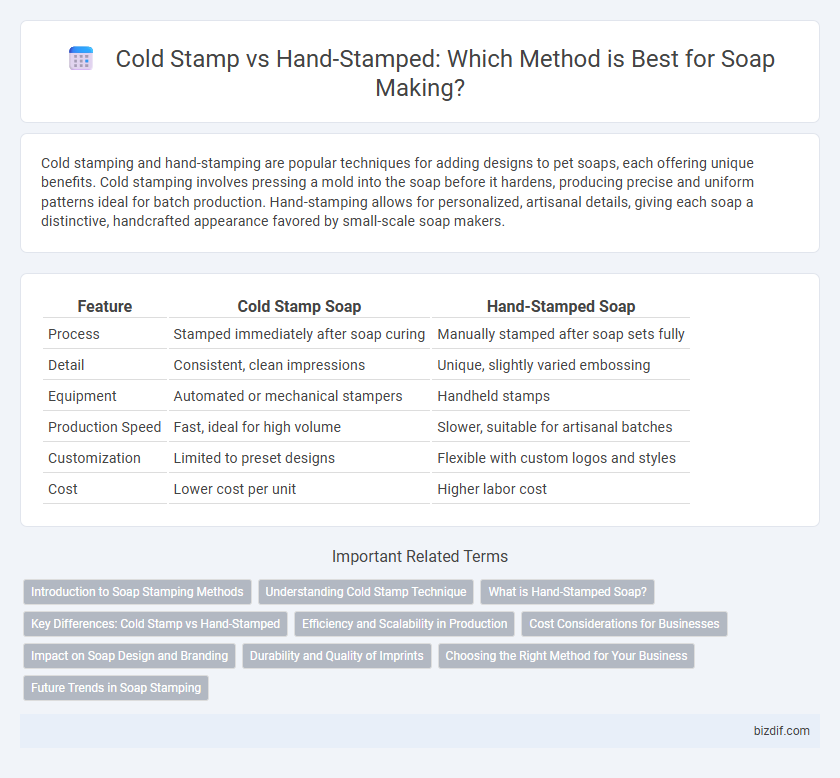

Cold stamping and hand-stamping are popular techniques for adding designs to pet soaps, each offering unique benefits. Cold stamping involves pressing a mold into the soap before it hardens, producing precise and uniform patterns ideal for batch production. Hand-stamping allows for personalized, artisanal details, giving each soap a distinctive, handcrafted appearance favored by small-scale soap makers.

Table of Comparison

| Feature | Cold Stamp Soap | Hand-Stamped Soap |

|---|---|---|

| Process | Stamped immediately after soap curing | Manually stamped after soap sets fully |

| Detail | Consistent, clean impressions | Unique, slightly varied embossing |

| Equipment | Automated or mechanical stampers | Handheld stamps |

| Production Speed | Fast, ideal for high volume | Slower, suitable for artisanal batches |

| Customization | Limited to preset designs | Flexible with custom logos and styles |

| Cost | Lower cost per unit | Higher labor cost |

Introduction to Soap Stamping Methods

Cold stamping involves pressing designs onto soap bars using pre-made, heat-resistant molds that create precise, consistent imprints without affecting the soap's texture or curing process. Hand-stamped soap uses manual tools such as metal or wooden stamps applied with pressure or ink, offering a customizable and artisanal finish that varies slightly with each impression. Both methods enhance branding and aesthetic appeal, but cold stamping is favored for uniformity in mass production while hand-stamping suits small-batch, bespoke soap makers.

Understanding Cold Stamp Technique

Cold stamp soap making uses silicone molds to create detailed impressions by pressing fresh soap batter without external heat, preserving fragrance and vibrant colors. This technique differs from hand-stamped methods where designs are manually carved or pressed onto cured soap bars, often requiring more time and precision. Cold stamping offers consistent, intricate patterns while maintaining the soap's natural texture and quality.

What is Hand-Stamped Soap?

Hand-stamped soap is crafted by pressing a personalized design or logo into the soap surface while it is still soft, creating a distinct and tactile impression. This technique enhances the soap's artisanal appeal and allows for custom branding or decorative elements. Unlike cold stamped soap, which uses pre-made molds or stamps during the curing process, hand-stamping offers greater flexibility for unique, one-of-a-kind designs.

Key Differences: Cold Stamp vs Hand-Stamped

Cold stamp soap involves pressing a pre-made design onto a fully cured soap bar, resulting in a clean, professional imprint with consistent depth and clarity. Hand-stamped soap uses individual stamps applied manually to soft or semi-cured soap, producing a more personalized, artisanal look with slight variations in impression. The primary differences lie in the timing of stamping and the uniformity of the final design, where cold stamping offers precision and hand-stamping delivers uniqueness.

Efficiency and Scalability in Production

Cold stamp soap making streamlines production by applying pre-designed patterns quickly, optimizing efficiency for large-scale batches and maintaining consistent quality. Hand-stamped methods require more time and skilled labor, limiting scalability but allowing for detailed customization and unique designs in small batches. Businesses targeting high-volume output benefit from cold stamping, while artisan soap makers prioritize hand-stamping for distinctiveness and craft appeal.

Cost Considerations for Businesses

Cold stamp soap molds offer a cost-effective solution for businesses by enabling faster production with reusable silicone molds, reducing material wastage and labor costs compared to hand-stamping methods. Hand-stamped soaps require skilled labor and more time per unit, leading to higher operational expenses, making them less scalable for large batch production. Investing in cold stamp technology enhances efficiency and lowers per-unit cost, supporting better profit margins in competitive soap-making markets.

Impact on Soap Design and Branding

Cold stamp techniques create intricate, consistent patterns that enhance soap design precision and brand recognition. Hand-stamped methods provide a unique, artisanal appearance, emphasizing craftsmanship and individuality in branding. Choosing between cold stamp and hand-stamped approaches directly influences the visual appeal and consumer perception of handmade soap products.

Durability and Quality of Imprints

Cold stamp soap designs offer higher durability due to deeper and more precise imprints created by pressing a cold mold onto the soap surface, ensuring long-lasting detail retention. Hand-stamped soaps often show slight variations in imprint depth and clarity, which can affect overall quality and longevity of the design. The cold stamp method produces consistent, crisp imprints that withstand handling and use better than the often softer, less defined hand-stamped impressions.

Choosing the Right Method for Your Business

Cold stamp soap making offers a precise, professional finish ideal for large-scale production, ensuring consistent branding with minimal manual effort. Hand-stamped soaps provide a unique, artisanal touch that appeals to niche markets valuing craftsmanship and customization despite slower output. Selecting the right method depends on your business goals: prioritize efficiency and uniformity with cold stamping or emphasize authenticity and small-batch uniqueness with hand-stamping.

Future Trends in Soap Stamping

Future trends in soap stamping reveal a growing preference for eco-friendly and personalized designs, with cold stamp techniques gaining popularity due to their precision and minimal waste. Hand-stamped soaps maintain their artisanal appeal but are increasingly integrated with new materials to enhance durability and detail. Innovations in biodegradable inks and customizable stamp molds are expected to drive the market, catering to consumer demand for sustainable and unique soap products.

Cold Stamp vs Hand-Stamped Infographic

bizdif.com

bizdif.com