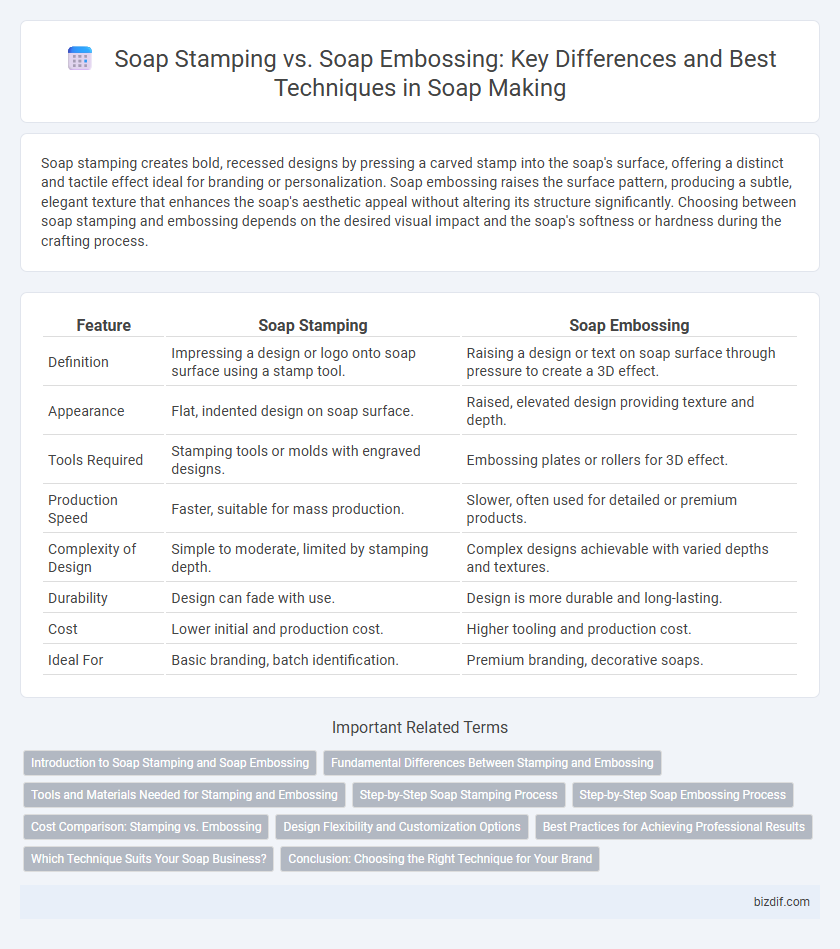

Soap stamping creates bold, recessed designs by pressing a carved stamp into the soap's surface, offering a distinct and tactile effect ideal for branding or personalization. Soap embossing raises the surface pattern, producing a subtle, elegant texture that enhances the soap's aesthetic appeal without altering its structure significantly. Choosing between soap stamping and embossing depends on the desired visual impact and the soap's softness or hardness during the crafting process.

Table of Comparison

| Feature | Soap Stamping | Soap Embossing |

|---|---|---|

| Definition | Impressing a design or logo onto soap surface using a stamp tool. | Raising a design or text on soap surface through pressure to create a 3D effect. |

| Appearance | Flat, indented design on soap surface. | Raised, elevated design providing texture and depth. |

| Tools Required | Stamping tools or molds with engraved designs. | Embossing plates or rollers for 3D effect. |

| Production Speed | Faster, suitable for mass production. | Slower, often used for detailed or premium products. |

| Complexity of Design | Simple to moderate, limited by stamping depth. | Complex designs achievable with varied depths and textures. |

| Durability | Design can fade with use. | Design is more durable and long-lasting. |

| Cost | Lower initial and production cost. | Higher tooling and production cost. |

| Ideal For | Basic branding, batch identification. | Premium branding, decorative soaps. |

Introduction to Soap Stamping and Soap Embossing

Soap stamping involves pressing a design or logo onto the surface of a soap bar using a carved stamp, creating clear and defined images or text for branding or decorative purposes. Soap embossing, in contrast, raises the design above the soap surface through a molding or pressing technique, offering a textured, three-dimensional effect that enhances the tactile and visual appeal of the soap. Both methods serve to customize soap bars with unique aesthetics, but soap stamping typically produces sharper, more precise details while embossing adds depth and texture.

Fundamental Differences Between Stamping and Embossing

Soap stamping involves pressing a design or text directly into the soap surface using a carved stamp, creating a clear, often shallow imprint. Soap embossing raises the soap's surface to form a design that stands out in relief, achieved by molding the soap with a raised pattern. The fundamental difference lies in stamping producing an indented image by compression, while embossing creates a raised, three-dimensional effect on the soap bar.

Tools and Materials Needed for Stamping and Embossing

Soap stamping requires specialized soap stamp molds typically made from durable materials like silicone, acrylic, or wood to create clear, raised designs on the soap surface. Embossing soap involves using heated embossing tools or metal embossing plates to press intricate patterns into softened soap bars, often with the aid of soft clay or embossing powders for added texture. Both techniques demand precise tools and quality materials such as glycerin-based soaps for better imprint clarity and heat resistance in embossing.

Step-by-Step Soap Stamping Process

Soap stamping involves pressing a carved or engraved stamp into the surface of cured soap bars to create detailed, raised designs. Begin by selecting a high-quality wooden or silicone soap stamp, ensuring the soap is firm and dry for a clear imprint. Press the stamp evenly and firmly onto the soap surface, hold for a few seconds, then gently lift to reveal a crisp, decorative impression.

Step-by-Step Soap Embossing Process

Soap embossing involves pressing a raised design into the soap surface using a custom die or stamp, creating a textured and decorative effect. The step-by-step soap embossing process begins with curing the soap until it reaches the ideal firmness, then aligning the embossing plate carefully over the soap bar before applying even pressure to transfer the design. This technique enhances the visual appeal of handmade soaps and allows for intricate patterns without compromising the soap's structural integrity.

Cost Comparison: Stamping vs. Embossing

Soap stamping typically incurs lower costs due to simpler tools and quicker application, making it ideal for small batches and artisanal products. Embossing involves more intricate molds and higher initial investment but provides a premium, detailed finish suitable for upscale markets. Choosing between stamping and embossing depends on balancing budget constraints with desired product aesthetics and production volume.

Design Flexibility and Customization Options

Soap stamping offers precise, sharp designs ideal for simple logos and text, allowing for consistent branding through engraved stamps. Soap embossing provides deeper, textured patterns that enhance tactile appeal and enable more intricate, three-dimensional designs with greater artistic versatility. Both methods support customization, but embossing excels in creating unique, elaborate visuals while stamping suits clearer, bold impressions.

Best Practices for Achieving Professional Results

For professional soap making, stamping offers precise, clear imprints suitable for branding and intricate designs, while embossing creates raised patterns that add texture and visual depth. Best practices include using firm but gentle pressure on a well-cured soap base to avoid cracking, ensuring the stamp or embossing tool is clean and dry, and experimenting with temperature and moisture levels to achieve crisp details. Consistent technique and high-quality tools are essential for achieving sharp, durable impressions that enhance the soap's aesthetic appeal.

Which Technique Suits Your Soap Business?

Soap stamping offers precise, bold logos ideal for small-batch or artisanal soap brands seeking strong brand identity, while soap embossing creates subtle, raised designs that enhance luxury appeal and tactile experience. Consider your target market and packaging style; stamping suits minimalist labels and cost-effective production, whereas embossing complements premium, hand-crafted products with detailed aesthetics. Evaluating production scale, budget, and brand positioning helps determine which technique best aligns with your soap business goals.

Conclusion: Choosing the Right Technique for Your Brand

Soap stamping offers precise branding with clear, sharp logos ideal for artisanal and luxury products, enhancing brand recognition through consistent imprint quality. Soap embossing provides a textured, three-dimensional effect that creates a premium tactile experience, making it suitable for high-end or specialty lines emphasizing craftsmanship. Selecting between soap stamping and embossing depends on your brand identity, product style, and desired customer engagement, ensuring the technique aligns with your marketing and aesthetic goals.

Soap Stamping vs Soap Embossing Infographic

bizdif.com

bizdif.com