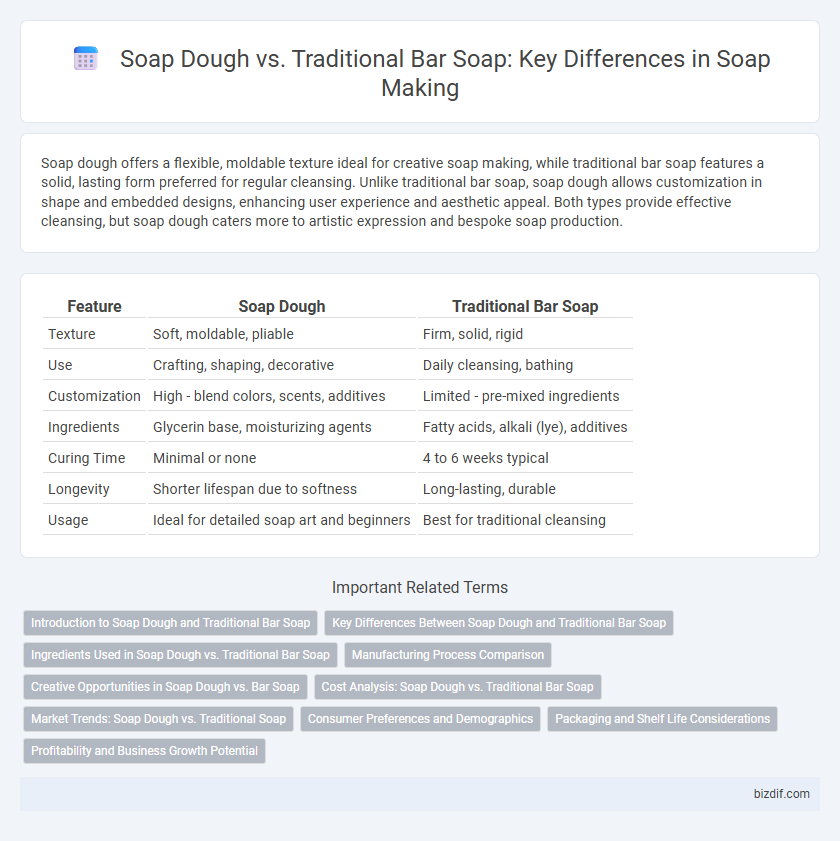

Soap dough offers a flexible, moldable texture ideal for creative soap making, while traditional bar soap features a solid, lasting form preferred for regular cleansing. Unlike traditional bar soap, soap dough allows customization in shape and embedded designs, enhancing user experience and aesthetic appeal. Both types provide effective cleansing, but soap dough caters more to artistic expression and bespoke soap production.

Table of Comparison

| Feature | Soap Dough | Traditional Bar Soap |

|---|---|---|

| Texture | Soft, moldable, pliable | Firm, solid, rigid |

| Use | Crafting, shaping, decorative | Daily cleansing, bathing |

| Customization | High - blend colors, scents, additives | Limited - pre-mixed ingredients |

| Ingredients | Glycerin base, moisturizing agents | Fatty acids, alkali (lye), additives |

| Curing Time | Minimal or none | 4 to 6 weeks typical |

| Longevity | Shorter lifespan due to softness | Long-lasting, durable |

| Usage | Ideal for detailed soap art and beginners | Best for traditional cleansing |

Introduction to Soap Dough and Traditional Bar Soap

Soap dough is a pliable, moldable soap base often used for crafting decorative soap shapes, offering flexibility in design compared to traditional bar soap. Traditional bar soap is a solid, pre-formed cleansing product made through saponification, valued for its durability and straightforward use. Soap dough allows customization and artistic expression, while traditional bar soap emphasizes practicality and consistency in everyday hygiene.

Key Differences Between Soap Dough and Traditional Bar Soap

Soap dough offers a pliable, moldable texture that allows for intricate designs and easy customization, unlike traditional bar soap which is solid and rigid. Soap dough typically contains a higher glycerin content, resulting in a softer, longer-lasting lather compared to the firm structure of traditional bar soap. The drying process of traditional bar soap involves curing over several weeks for hardness and longevity, whereas soap dough remains soft and pliable, ideal for decorative or seasonal creations.

Ingredients Used in Soap Dough vs. Traditional Bar Soap

Soap dough typically contains a higher concentration of oils, shea butter, and glycerin, providing a soft, moldable texture ideal for crafting and decorating. Traditional bar soap relies more on a balanced combination of alkali (lye) and fats such as coconut or palm oil, resulting in a hard, long-lasting bar that lathers effectively. The ingredient variations directly influence the soap's texture, usability, and appearance, with soap dough emphasizing pliability and moisture retention, while traditional bar soap prioritizes durability and cleansing properties.

Manufacturing Process Comparison

Soap dough manufacturing involves mixing oils, lye, and additives into a pliable, thick paste that can be molded or extruded before curing, allowing for greater customization in shapes and textures. Traditional bar soap production requires a saponification process where oils and lye react directly, followed by a curing period ranging from weeks to months to harden the soap. Soap dough's process is generally faster and more flexible, while traditional bar soap emphasizes a time-intensive curing step to enhance hardness and longevity.

Creative Opportunities in Soap Dough vs. Bar Soap

Soap dough offers unparalleled creative opportunities compared to traditional bar soap by allowing intricate shaping, layering, and embedding of various colors and textures before curing. Unlike conventional bar soap, which is typically limited to simple molds, soap dough's pliable consistency enables detailed sculpting and customization, making it ideal for artistic soap designs and unique product differentiation. Its flexibility supports experimentation with additives and patterns, enhancing both aesthetic appeal and functional variety in handmade soap creations.

Cost Analysis: Soap Dough vs. Traditional Bar Soap

Soap dough typically incurs higher initial material costs due to specialized conditioning agents and packaging, while traditional bar soap benefits from lower production expenses and bulk manufacturing efficiencies. However, soap dough offers extended usability and less waste, potentially reducing long-term costs for consumers despite its premium price point. Cost analysis reveals that traditional bar soap remains more economical for mass use, whereas soap dough appeals to niche markets prioritizing texture and application control.

Market Trends: Soap Dough vs. Traditional Soap

Soap dough is gaining traction in the soap making market due to its customization and ease of use, appealing to both hobbyists and small businesses. Traditional bar soap maintains a solid presence driven by consumer preference for classic textures and established brands. Market trends indicate a growing niche for soap dough as sustainable and innovative formulations attract eco-conscious customers seeking personalized skincare options.

Consumer Preferences and Demographics

Soap dough appeals primarily to younger consumers and DIY enthusiasts who value customization and creativity in personal care products, while traditional bar soap remains favored by older demographics seeking simplicity and familiarity. Studies indicate millennials and Gen Z consumers prioritize natural ingredients and eco-friendly packaging found in soap dough kits, whereas baby boomers prefer the convenience and consistent quality of conventional soap bars. Market trends reveal a growing preference for soap dough in urban areas with higher disposable incomes, reflecting shifting consumer behavior toward experiential and artisanal products.

Packaging and Shelf Life Considerations

Soap dough offers flexible packaging options, often using airtight containers to maintain moisture levels, which helps extend its shelf life compared to traditional bar soap. Traditional bar soap typically requires paper or plastic wrapping to protect it from humidity and physical damage, with a naturally longer shelf life due to its solid form. Proper storage conditions, such as a cool, dry environment, are crucial for both types to prevent degradation and maintain product quality over time.

Profitability and Business Growth Potential

Soap dough offers greater profitability and business growth potential compared to traditional bar soap due to its flexibility in customization, reduced waste, and lower production costs. It enables small-batch production and rapid market testing, allowing entrepreneurs to respond quickly to consumer trends and preferences. The increased efficiency and scalability of soap dough can lead to higher profit margins and accelerated brand expansion in competitive markets.

Soap Dough vs Traditional Bar Soap Infographic

bizdif.com

bizdif.com