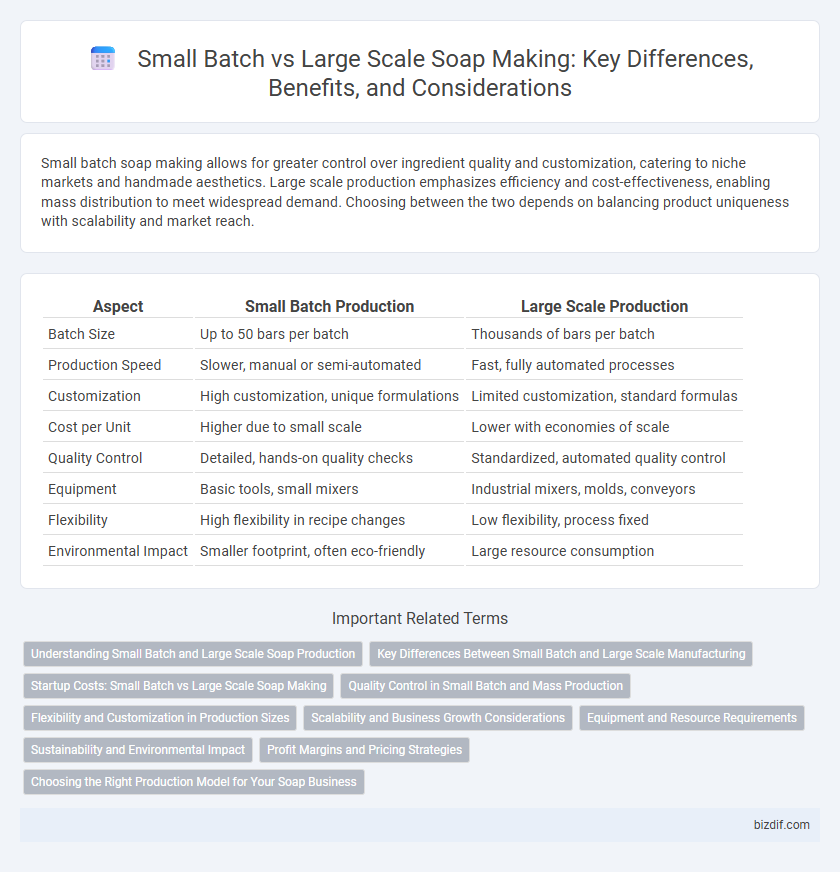

Small batch soap making allows for greater control over ingredient quality and customization, catering to niche markets and handmade aesthetics. Large scale production emphasizes efficiency and cost-effectiveness, enabling mass distribution to meet widespread demand. Choosing between the two depends on balancing product uniqueness with scalability and market reach.

Table of Comparison

| Aspect | Small Batch Production | Large Scale Production |

|---|---|---|

| Batch Size | Up to 50 bars per batch | Thousands of bars per batch |

| Production Speed | Slower, manual or semi-automated | Fast, fully automated processes |

| Customization | High customization, unique formulations | Limited customization, standard formulas |

| Cost per Unit | Higher due to small scale | Lower with economies of scale |

| Quality Control | Detailed, hands-on quality checks | Standardized, automated quality control |

| Equipment | Basic tools, small mixers | Industrial mixers, molds, conveyors |

| Flexibility | High flexibility in recipe changes | Low flexibility, process fixed |

| Environmental Impact | Smaller footprint, often eco-friendly | Large resource consumption |

Understanding Small Batch and Large Scale Soap Production

Small batch soap production allows for greater control over ingredient quality and customization, making it ideal for artisans and niche markets seeking unique formulations. Large scale soap production leverages automated processes and standardized recipes to achieve higher efficiency, consistency, and lower cost per unit, catering to mass-market demand. Understanding the differences in scale helps manufacturers optimize resources, maintain product integrity, and meet diverse consumer expectations.

Key Differences Between Small Batch and Large Scale Manufacturing

Small batch soap making emphasizes artisanal quality, precise ingredient control, and customization, producing limited quantities ideal for niche markets or personal use. Large scale manufacturing leverages automated processes, high-volume output, and cost efficiencies to meet extensive demand in retail and industrial sectors. Key differences include production speed, ingredient sourcing, quality consistency, and operational flexibility.

Startup Costs: Small Batch vs Large Scale Soap Making

Small batch soap making requires lower startup costs, as it involves purchasing minimal equipment and raw materials, making it ideal for hobbyists and small businesses. Large scale production demands significant investment in industrial machinery, bulk ingredients, and facility space, increasing initial expenses but enabling higher output and economies of scale. Careful budget planning is essential to balance cost efficiency and production capacity when choosing between small batch and large scale soap manufacturing.

Quality Control in Small Batch and Mass Production

Small batch soap making ensures meticulous quality control through hands-on monitoring and precise ingredient measurement, resulting in consistently high-quality products with unique characteristics. In contrast, large-scale mass production relies on automated processes and standardized formulations, which can lead to faster output but may compromise customization and the artisan touch. Effective quality control in mass production depends on rigorous testing protocols and statistical process control to maintain product consistency across extensive batches.

Flexibility and Customization in Production Sizes

Small batch soap making offers superior flexibility, allowing artisans to easily customize formulas and experiment with unique ingredients, catering to niche markets and personalized orders. Large scale production prioritizes efficiency and uniformity, optimizing cost per unit but limiting the ability to modify batches quickly or tailor products for individual preferences. This contrast in production sizes significantly impacts innovation potential and responsiveness to market trends in the soap industry.

Scalability and Business Growth Considerations

Small batch soap making offers precise control over ingredient quality and customization, ideal for niche markets and artisanal branding but limits rapid scalability due to labor intensity and equipment constraints. Large scale production enhances output volume and cost efficiency, supporting broader distribution and faster business growth, though it may compromise product uniqueness and require significant upfront investment. Evaluating scalability involves balancing production capacity, market demand, and capital resources to align with long-term business growth objectives.

Equipment and Resource Requirements

Small batch soap making requires minimal equipment such as basic molds, handheld mixers, and smaller curing racks, making it ideal for artisanal and customized products. Large scale production demands industrial-grade machinery including automated mixers, continuous soap cutters, and extensive curing facilities to ensure consistency and higher output. Resource allocation in large scale setups also involves bulk purchasing of raw materials and specialized workforce management to optimize production efficiency.

Sustainability and Environmental Impact

Small batch soap making promotes sustainability by minimizing waste and allowing precise control over ingredient quality and sourcing, often using organic and biodegradable components. Large scale production typically relies on synthetic chemicals and mass packaging, which can increase carbon footprint and generate significant environmental waste. Prioritizing small batch production supports eco-friendly practices by reducing energy consumption and limiting harmful emissions throughout the soap manufacturing process.

Profit Margins and Pricing Strategies

Small batch soap making often allows for higher profit margins due to artisanal appeal and the ability to charge premium prices. Large scale production benefits from economies of scale, reducing per-unit costs and enabling competitive pricing in mass markets. Pricing strategies for small batches emphasize uniqueness and quality, whereas large scale focuses on volume sales and cost efficiency.

Choosing the Right Production Model for Your Soap Business

Selecting the appropriate production model for your soap business significantly impacts efficiency, cost management, and product quality. Small batch production allows for greater customization, flexibility, and attention to detail, ideal for artisan and niche markets. Large scale production maximizes output and reduces per-unit cost, suitable for meeting high demand and expanding distribution channels.

Small Batch vs Large Scale Production Infographic

bizdif.com

bizdif.com