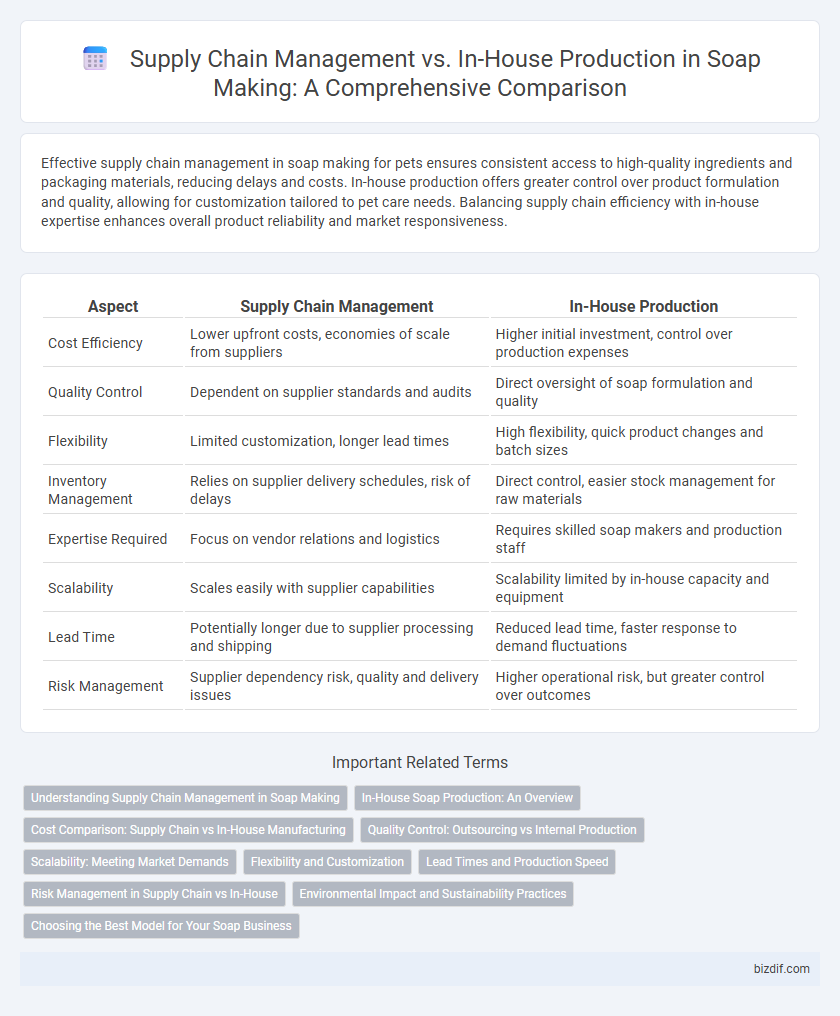

Effective supply chain management in soap making for pets ensures consistent access to high-quality ingredients and packaging materials, reducing delays and costs. In-house production offers greater control over product formulation and quality, allowing for customization tailored to pet care needs. Balancing supply chain efficiency with in-house expertise enhances overall product reliability and market responsiveness.

Table of Comparison

| Aspect | Supply Chain Management | In-House Production |

|---|---|---|

| Cost Efficiency | Lower upfront costs, economies of scale from suppliers | Higher initial investment, control over production expenses |

| Quality Control | Dependent on supplier standards and audits | Direct oversight of soap formulation and quality |

| Flexibility | Limited customization, longer lead times | High flexibility, quick product changes and batch sizes |

| Inventory Management | Relies on supplier delivery schedules, risk of delays | Direct control, easier stock management for raw materials |

| Expertise Required | Focus on vendor relations and logistics | Requires skilled soap makers and production staff |

| Scalability | Scales easily with supplier capabilities | Scalability limited by in-house capacity and equipment |

| Lead Time | Potentially longer due to supplier processing and shipping | Reduced lead time, faster response to demand fluctuations |

| Risk Management | Supplier dependency risk, quality and delivery issues | Higher operational risk, but greater control over outcomes |

Understanding Supply Chain Management in Soap Making

Effective supply chain management in soap making involves overseeing procurement of raw materials like oils, lye, and fragrances to ensure consistent quality and timely delivery. It optimizes inventory control, reduces costs, and streamlines production scheduling to meet market demand efficiently. Leveraging supplier relationships and logistics coordination enables soap manufacturers to maintain product availability and respond swiftly to changes in consumer preferences.

In-House Soap Production: An Overview

In-house soap production offers complete control over ingredient quality, formulation, and production timelines, which enhances product consistency and customization. By managing raw materials and manufacturing internally, businesses can reduce dependency on suppliers and mitigate supply chain risks. This approach also enables rapid experimentation with new recipes and swift response to market demands, optimizing overall operational flexibility.

Cost Comparison: Supply Chain vs In-House Manufacturing

Supply chain management in soap making often reduces upfront costs by outsourcing raw materials and production processes to specialized vendors, lowering capital expenditure on equipment and labor. In-house manufacturing requires significant investment in machinery, skilled labor, and inventory management but offers better control over production quality and timelines. Evaluating cost efficiency depends on volume, flexibility needs, and the ability to manage operational overhead versus supplier reliability and pricing stability.

Quality Control: Outsourcing vs Internal Production

In soap making, internal production allows for stringent quality control by enabling direct supervision of ingredient sourcing, formulation, and production processes. Outsourcing supply chain management may introduce variability in raw material quality and production standards, potentially impacting the consistency and safety of the final soap product. Maintaining in-house production provides greater transparency and immediate corrective action opportunities, ensuring the highest quality control throughout the manufacturing cycle.

Scalability: Meeting Market Demands

Supply chain management offers greater scalability in soap making by enabling manufacturers to quickly adjust production volumes through external suppliers and distribution networks, meeting fluctuating market demands efficiently. In-house production limits scalability due to fixed capacity constraints and resource availability, often resulting in slower response times to demand surges. Leveraging external supply chains facilitates rapid expansion and access to diverse raw materials, essential for scaling operations in competitive soap markets.

Flexibility and Customization

In soap making, supply chain management offers scalability but often limits flexibility due to reliance on external suppliers with fixed product specifications. In-house production enables greater customization of ingredients, scents, and formulations, allowing makers to quickly adapt to market trends and consumer preferences. This direct control accelerates innovation cycles and personalized product development, enhancing responsiveness in a competitive market.

Lead Times and Production Speed

Supply chain management in soap making often involves longer lead times due to reliance on external suppliers for raw materials, which can delay production schedules. In-house production enables faster turnaround by directly controlling ingredient sourcing and manufacturing processes, significantly reducing lead times. Optimizing inventory and workflow internally accelerates production speed and ensures timely order fulfillment.

Risk Management in Supply Chain vs In-House

In soap making, risk management in supply chain management involves mitigating disruptions by diversifying suppliers and ensuring raw material quality through rigorous audits. In-house production minimizes dependence on external vendors, allowing tighter control over inventory and production schedules but increases exposure to operational risks like equipment failure and labor shortages. Balancing supply chain flexibility with in-house operational control is critical to maintaining consistent soap production and meeting market demands.

Environmental Impact and Sustainability Practices

Supply chain management in soap making often involves sourcing raw materials from multiple suppliers, which can increase the carbon footprint due to transportation emissions, whereas in-house production allows for tighter control over sustainable sourcing and waste reduction. Implementing sustainable practices such as using organic ingredients and biodegradable packaging is more feasible when production is managed internally, minimizing environmental impact. Efficient supply chain management can still support sustainability by prioritizing local suppliers and eco-friendly logistics to reduce energy consumption and pollution.

Choosing the Best Model for Your Soap Business

Evaluating supply chain management versus in-house production in soap making hinges on factors such as cost efficiency, quality control, and scalability. Outsourcing raw materials and packaging through reliable suppliers can reduce overhead and streamline operations, while in-house production allows for greater customization and immediate adjustments to formulations. Businesses should assess their production volume, market demand, and resource availability to choose the most strategic model that maximizes profitability and maintains consistent product quality.

Supply Chain Management vs In-House Production Infographic

bizdif.com

bizdif.com