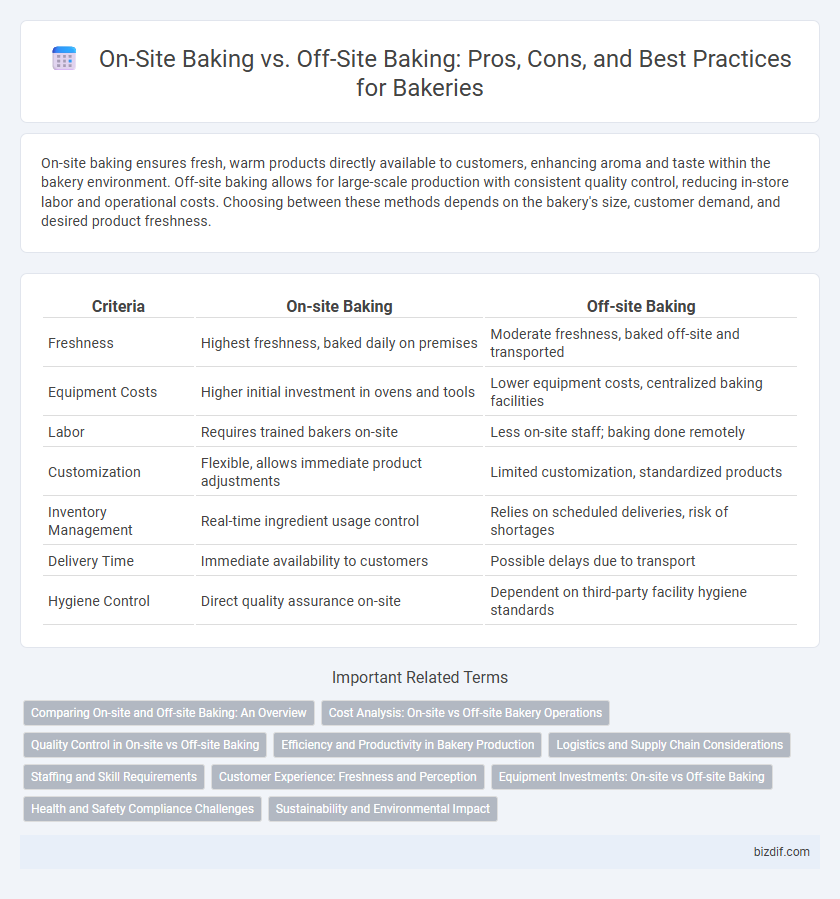

On-site baking ensures fresh, warm products directly available to customers, enhancing aroma and taste within the bakery environment. Off-site baking allows for large-scale production with consistent quality control, reducing in-store labor and operational costs. Choosing between these methods depends on the bakery's size, customer demand, and desired product freshness.

Table of Comparison

| Criteria | On-site Baking | Off-site Baking |

|---|---|---|

| Freshness | Highest freshness, baked daily on premises | Moderate freshness, baked off-site and transported |

| Equipment Costs | Higher initial investment in ovens and tools | Lower equipment costs, centralized baking facilities |

| Labor | Requires trained bakers on-site | Less on-site staff; baking done remotely |

| Customization | Flexible, allows immediate product adjustments | Limited customization, standardized products |

| Inventory Management | Real-time ingredient usage control | Relies on scheduled deliveries, risk of shortages |

| Delivery Time | Immediate availability to customers | Possible delays due to transport |

| Hygiene Control | Direct quality assurance on-site | Dependent on third-party facility hygiene standards |

Comparing On-site and Off-site Baking: An Overview

On-site baking allows bakeries to produce fresh products directly at the sales location, ensuring immediate availability and enhanced aroma that attracts customers. Off-site baking centralizes production in a specialized facility, often increasing efficiency, consistency, and scalability while potentially reducing labor and equipment costs at retail sites. Both methods impact product freshness, operational complexity, and supply chain logistics, requiring bakeries to balance quality control with cost management based on their size and customer demand.

Cost Analysis: On-site vs Off-site Bakery Operations

On-site baking typically incurs higher labor and utility costs due to the need for skilled bakers and specialized equipment, while off-site baking benefits from economies of scale and shared resources, reducing overall expenses. However, on-site operations can minimize transportation costs and ensure fresher products, potentially increasing customer satisfaction and sales. A detailed cost analysis comparing ingredient procurement, labor, energy consumption, and logistics reveals that off-site baking often lowers fixed costs but may increase variable costs associated with distribution.

Quality Control in On-site vs Off-site Baking

On-site baking allows for real-time quality control, ensuring freshness and precise adherence to recipes, while off-site baking often faces challenges with product consistency during transportation and storage. On-site facilities can immediately address any deviations in texture, moisture, or flavor, maintaining superior product standards. Off-site baking requires strict logistical coordination and advanced preservation techniques to minimize quality degradation before reaching consumers.

Efficiency and Productivity in Bakery Production

On-site baking enhances freshness and allows real-time quality control, significantly improving bakery production efficiency through immediate adjustments. Off-site baking centralizes production, optimizing labor and resource allocation, which boosts productivity by enabling bulk baking and streamlined logistics. Balancing on-site and off-site baking strategies maximizes overall bakery output while maintaining product consistency and reducing operational costs.

Logistics and Supply Chain Considerations

On-site baking streamlines logistics by reducing transportation needs, ensuring fresher products and quicker turnaround times, while off-site baking centralizes production, enabling bulk ingredient sourcing and optimized distribution routes. Supply chain efficiency in off-site baking relies heavily on reliable cold chain management and synchronized delivery schedules to maintain product quality upon arrival. On-site baking demands more localized inventory management and skilled labor, whereas off-site baking benefits from economies of scale but requires robust coordination between production and retail locations.

Staffing and Skill Requirements

On-site baking demands skilled bakers and pastry chefs capable of managing the entire production process from raw ingredients to finished products, ensuring freshness and customization. Off-site baking centralizes production in larger facilities staffed with specialized teams focusing on efficiency, consistency, and volume, requiring expertise in industrial baking equipment and quality control. Staffing for on-site baking often involves smaller teams with versatile skills, while off-site baking relies on segmented roles and higher technical proficiency to maintain large-scale operations.

Customer Experience: Freshness and Perception

On-site baking ensures customers receive products at peak freshness, enhancing the sensory experience with warm aromas and soft textures that reinforce quality perception. Off-site baking offers consistency and scalability but may compromise immediate freshness, potentially impacting customer satisfaction and brand loyalty. The direct visibility of baking processes on-site also builds trust and engagement, fostering a stronger connection between the bakery and its customers.

Equipment Investments: On-site vs Off-site Baking

On-site baking requires substantial investment in ovens, proofers, mixers, and ventilation systems to support daily production, ensuring freshness and customization. Off-site baking centralizes equipment investments into large-scale, specialized facilities that benefit from economies of scale, reducing per-unit costs but demanding advanced logistics for distribution. Choosing between on-site and off-site baking equipment investments depends on production volume, freshness priorities, and budget constraints in bakery operations.

Health and Safety Compliance Challenges

On-site baking ensures immediate quality control but demands rigorous health and safety compliance with stringent hygiene protocols and equipment maintenance in a confined space. Off-site baking centralizes production, facilitating standardized safety measures and reducing cross-contamination risks but requires robust transportation and storage regulations to maintain product safety. Both methods face challenges in adhering to local food safety standards, worker safety regulations, and effective hazard analysis and critical control points (HACCP) implementation.

Sustainability and Environmental Impact

On-site baking reduces carbon emissions by minimizing transportation needs and energy consumption associated with moving goods, supporting local sourcing of ingredients to decrease environmental footprint. Off-site baking centralizes production, which can optimize energy use through advanced equipment and economies of scale but may increase distribution-related pollution. Evaluating sustainability involves balancing local energy savings against the potential efficiency of large-scale off-site facilities and their impact on supply chain emissions.

On-site Baking vs Off-site Baking Infographic

bizdif.com

bizdif.com