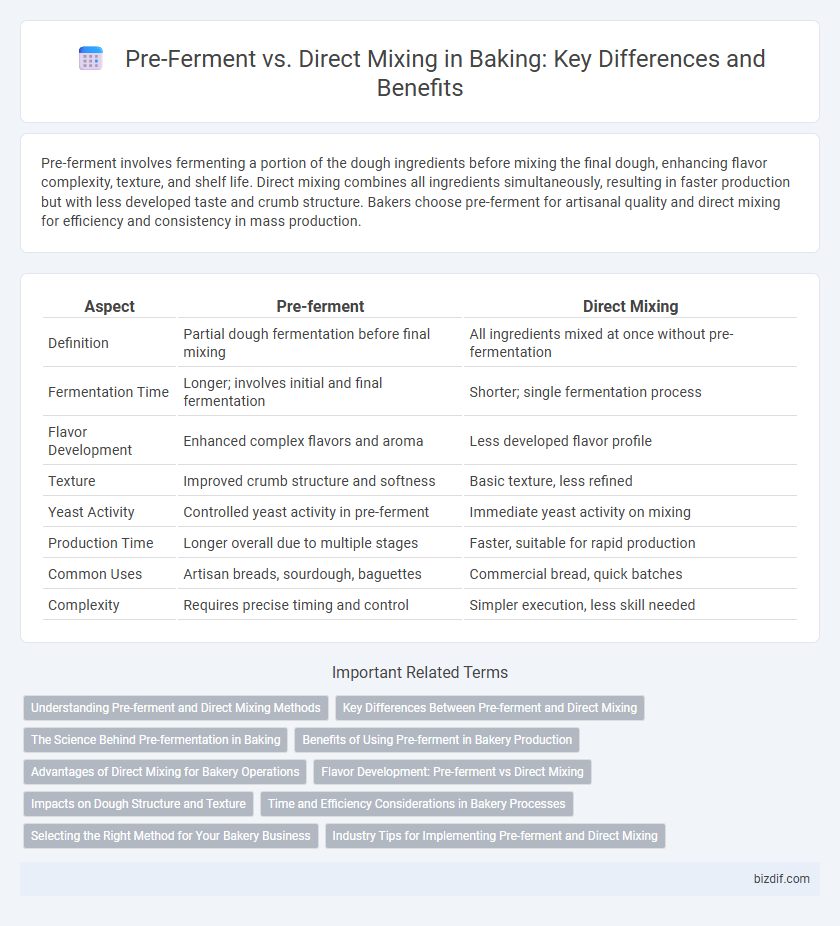

Pre-ferment involves fermenting a portion of the dough ingredients before mixing the final dough, enhancing flavor complexity, texture, and shelf life. Direct mixing combines all ingredients simultaneously, resulting in faster production but with less developed taste and crumb structure. Bakers choose pre-ferment for artisanal quality and direct mixing for efficiency and consistency in mass production.

Table of Comparison

| Aspect | Pre-ferment | Direct Mixing |

|---|---|---|

| Definition | Partial dough fermentation before final mixing | All ingredients mixed at once without pre-fermentation |

| Fermentation Time | Longer; involves initial and final fermentation | Shorter; single fermentation process |

| Flavor Development | Enhanced complex flavors and aroma | Less developed flavor profile |

| Texture | Improved crumb structure and softness | Basic texture, less refined |

| Yeast Activity | Controlled yeast activity in pre-ferment | Immediate yeast activity on mixing |

| Production Time | Longer overall due to multiple stages | Faster, suitable for rapid production |

| Common Uses | Artisan breads, sourdough, baguettes | Commercial bread, quick batches |

| Complexity | Requires precise timing and control | Simpler execution, less skill needed |

Understanding Pre-ferment and Direct Mixing Methods

Pre-ferment involves fermenting a portion of the dough ingredients separately before mixing with the final dough, enhancing flavor, texture, and shelf life through extended fermentation. Direct mixing combines all ingredients at once, resulting in quicker dough preparation but less complex flavor development. Bakers choose pre-ferment methods like poolish, biga, or sponge to optimize fermentation control and dough strength, while direct mixing suits rapid production and simpler recipes.

Key Differences Between Pre-ferment and Direct Mixing

Pre-ferment involves fermenting a portion of the dough ingredients before mixing with the remaining components, enhancing flavor development, dough strength, and shelf life. Direct mixing combines all ingredients simultaneously, producing quicker results but with less nuanced taste and texture. The choice affects fermentation time, complexity of flavor, and the final bread's crumb and crust characteristics.

The Science Behind Pre-fermentation in Baking

Pre-fermentation in baking enhances dough flavor and texture through controlled yeast activity and enzymatic reactions, producing organic acids and alcohols that improve crumb structure and shelf life. This process leads to better gluten development and increased dough extensibility compared to direct mixing, where ingredients combine instantly without fermentation time. The biochemical changes during pre-fermentation contribute to complex aromas and improved fermentation tolerance in the final bread product.

Benefits of Using Pre-ferment in Bakery Production

Pre-ferment enhances bread flavor and improves crumb texture by allowing natural yeast fermentation before the final dough mixing. It extends shelf life and boosts dough strength, making the baking process more consistent and efficient. Using pre-ferment also contributes to better fermentation control and nutrient availability, resulting in superior quality bakery products.

Advantages of Direct Mixing for Bakery Operations

Direct mixing streamlines bakery operations by reducing preparation time and minimizing ingredient handling, which lowers labor costs and decreases the risk of contamination. This method enhances production efficiency and allows for quicker turnaround times, ideal for high-volume bakeries. By eliminating the need for separate fermentation stages, direct mixing simplifies workflow while maintaining product consistency.

Flavor Development: Pre-ferment vs Direct Mixing

Pre-ferment techniques, such as poolish or biga, enhance flavor development by allowing natural fermentation to generate complex organic acids and alcohols, which improve aroma and taste depth. Direct mixing skips this prolonged fermentation, resulting in a simpler, less nuanced flavor profile due to limited enzymatic activity and reduced yeast byproducts. Bakers aiming for rich, artisan-quality bread typically prefer pre-fermentation to unlock deeper, more robust flavors.

Impacts on Dough Structure and Texture

Pre-ferment methods, such as poolish or biga, enhance dough structure by promoting gluten development and enzyme activity, resulting in a more open crumb and complex flavor profile. Direct mixing typically produces a tighter crumb and denser texture due to shorter fermentation times and reduced enzymatic action. The choice between pre-ferment and direct mixing significantly impacts dough extensibility, gas retention, and final bread texture.

Time and Efficiency Considerations in Bakery Processes

Pre-ferment techniques, such as poolish or biga, extend fermentation time but enhance dough flavor and improve crumb structure, making them ideal for artisanal bakery products. Direct mixing accelerates production by combining all ingredients simultaneously, reducing time and streamlining workflow, which benefits high-volume commercial bakeries. Choosing between pre-ferment and direct mixing impacts both the timing of production schedules and overall operational efficiency in bakery processes.

Selecting the Right Method for Your Bakery Business

Choosing between pre-ferment and direct mixing methods depends on your bakery's desired flavor profile, production timeline, and product consistency. Pre-ferment techniques enhance dough flavor and texture through extended fermentation but require more time and careful temperature control, ideal for artisan breads. Direct mixing offers faster production with simpler process control, making it suitable for high-volume bakeries focusing on efficiency and uniformity.

Industry Tips for Implementing Pre-ferment and Direct Mixing

Pre-ferment methods, such as poolish or biga, enhance flavor complexity and improve dough extensibility, resulting in superior crust texture and aroma, favored in artisan bakery production. Direct mixing streamlines workflow and reduces fermentation time, suitable for high-volume commercial bakeries aiming for consistent output and faster turnaround. Industry best practices recommend balancing fermentation control with operational efficiency by selecting pre-fermentation for premium products and direct mixing for mass production, optimizing yeast activity, dough hydration, and resting periods accordingly.

Pre-ferment vs Direct mixing Infographic

bizdif.com

bizdif.com