Traditional kneading involves manually working the dough, which enhances gluten development and allows bakers to gauge texture through touch, resulting in a more artisanal bread with unique texture and flavor. Mechanical kneading uses machines to mix and knead dough efficiently, providing consistent results and saving time in large-scale production. While traditional methods emphasize craftsmanship, mechanical kneading ensures uniformity and scalability in baking.

Table of Comparison

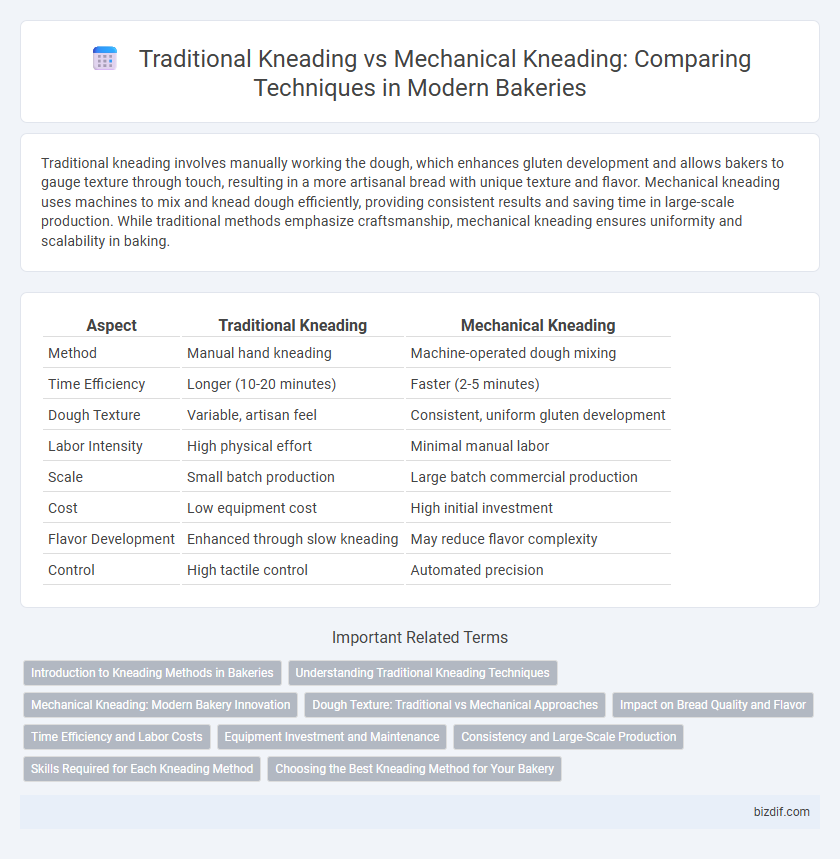

| Aspect | Traditional Kneading | Mechanical Kneading |

|---|---|---|

| Method | Manual hand kneading | Machine-operated dough mixing |

| Time Efficiency | Longer (10-20 minutes) | Faster (2-5 minutes) |

| Dough Texture | Variable, artisan feel | Consistent, uniform gluten development |

| Labor Intensity | High physical effort | Minimal manual labor |

| Scale | Small batch production | Large batch commercial production |

| Cost | Low equipment cost | High initial investment |

| Flavor Development | Enhanced through slow kneading | May reduce flavor complexity |

| Control | High tactile control | Automated precision |

Introduction to Kneading Methods in Bakeries

Traditional kneading involves manually working dough to develop gluten and evenly distribute ingredients, enhancing texture and flavor through tactile control. Mechanical kneading employs mixers and dough sheeters to increase efficiency and consistency, enabling large-scale production with precise timing and speed settings. Both methods play vital roles in bakeries, balancing artisanal quality and commercial demands.

Understanding Traditional Kneading Techniques

Traditional kneading techniques emphasize tactile feedback and manual control, allowing bakers to gauge dough consistency and develop gluten structure naturally. Hand kneading enhances the dough's texture by evenly distributing ingredients and incorporating air, which contributes to the bread's crumb and rise. This method preserves artisanal quality, connecting bakers to time-tested practices that influence flavor and crust formation.

Mechanical Kneading: Modern Bakery Innovation

Mechanical kneading revolutionizes bakery production by using automated mixers that ensure consistent dough texture and reduce labor intensity. This innovation accelerates dough development through controlled speed and pressure, enhancing gluten formation for superior bread quality. Modern bakeries benefit from mechanical kneading's efficiency, uniformity, and ability to scale production while maintaining product standards.

Dough Texture: Traditional vs Mechanical Approaches

Traditional kneading develops dough texture through manual folding and pressing, promoting gluten network formation that results in a slightly uneven yet artisanal crumb structure. Mechanical kneading, using mixers or dough machines, ensures consistent gluten development and uniform dough elasticity, producing a more predictable and uniform texture. The choice between methods impacts crumb softness, chewiness, and overall bread quality in bakery products.

Impact on Bread Quality and Flavor

Traditional kneading enhances bread quality by promoting natural gluten development and enzymatic activity, resulting in superior texture and richer flavor complexity. Mechanical kneading accelerates the process, offering consistency and efficiency but may produce bread with a slightly less nuanced taste and a firmer crumb. Studies show that artisanal methods yield higher sensory appeal, while industrial kneading supports large-scale production demands.

Time Efficiency and Labor Costs

Traditional kneading involves manual effort that is time-consuming and increases labor costs due to prolonged preparation periods. Mechanical kneading machines significantly reduce dough preparation time, enhancing productivity by performing consistent, high-speed mixing with minimal human intervention. This automation lowers labor expenses and optimizes bakery operations by allowing bakers to allocate time to other critical tasks.

Equipment Investment and Maintenance

Traditional kneading requires minimal equipment investment, typically involving just a sturdy wooden board and hands, reducing initial costs significantly. Mechanical kneading demands higher upfront expenditure for mixers and maintenance tools, along with ongoing costs due to wear and tear on motorized components. Regular upkeep of mechanical kneaders is essential to ensure consistent dough quality and extend equipment lifespan, impacting long-term operational expenses.

Consistency and Large-Scale Production

Traditional kneading offers artisanal control, resulting in variable dough texture and consistency that depends on the baker's technique. Mechanical kneading ensures uniform dough by standardizing mixing times and speeds, ideal for large-scale production. Industrial bakeries rely on mechanical kneading to maintain consistent quality and streamline batch processing.

Skills Required for Each Kneading Method

Traditional kneading demands manual dexterity, tactile sensitivity, and experience to gauge dough consistency and develop gluten structures effectively. Mechanical kneading relies on precise machine settings and knowledge of equipment operation to ensure consistent dough texture and hydration levels. Mastery of traditional techniques fosters artisanal quality, while mechanical kneading emphasizes efficiency and uniformity in commercial bakeries.

Choosing the Best Kneading Method for Your Bakery

Traditional kneading enhances dough texture by incorporating hands-on control and natural fermentation, resulting in artisanal flavor and crumb structure prized in specialty bakeries. Mechanical kneading offers consistency, speed, and scalability, ideal for high-volume production while maintaining dough elasticity and gluten development. Evaluating bakery size, product variety, and desired dough characteristics guides the optimal choice between hands-on craftsmanship and automated efficiency.

Traditional kneading vs Mechanical kneading Infographic

bizdif.com

bizdif.com