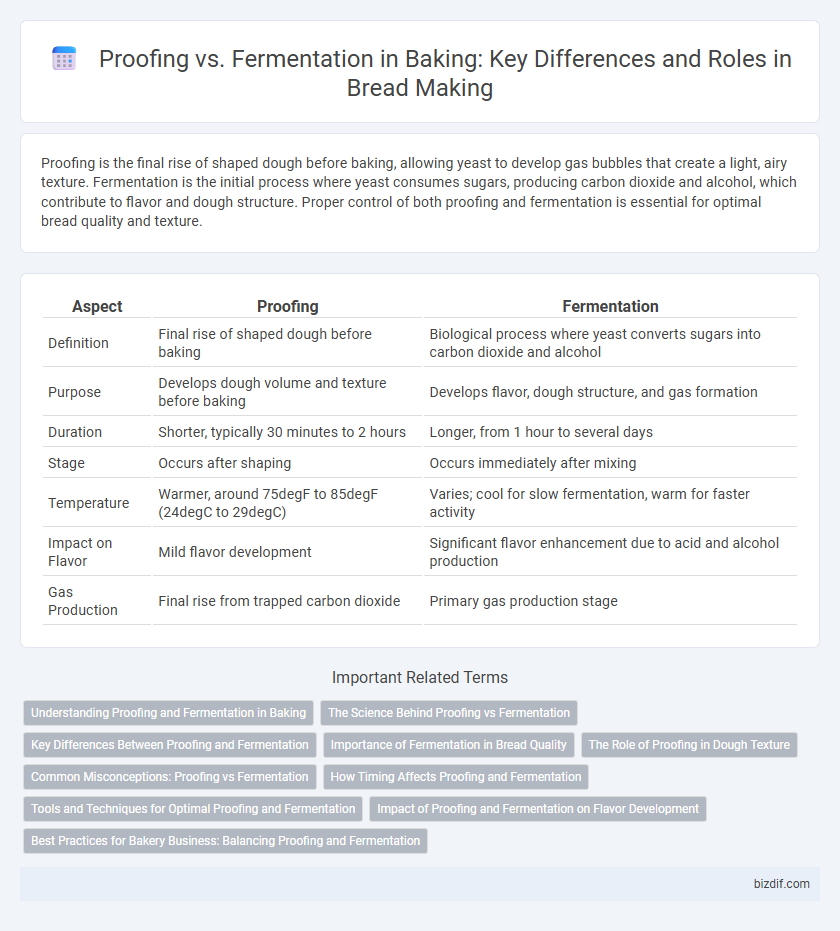

Proofing is the final rise of shaped dough before baking, allowing yeast to develop gas bubbles that create a light, airy texture. Fermentation is the initial process where yeast consumes sugars, producing carbon dioxide and alcohol, which contribute to flavor and dough structure. Proper control of both proofing and fermentation is essential for optimal bread quality and texture.

Table of Comparison

| Aspect | Proofing | Fermentation |

|---|---|---|

| Definition | Final rise of shaped dough before baking | Biological process where yeast converts sugars into carbon dioxide and alcohol |

| Purpose | Develops dough volume and texture before baking | Develops flavor, dough structure, and gas formation |

| Duration | Shorter, typically 30 minutes to 2 hours | Longer, from 1 hour to several days |

| Stage | Occurs after shaping | Occurs immediately after mixing |

| Temperature | Warmer, around 75degF to 85degF (24degC to 29degC) | Varies; cool for slow fermentation, warm for faster activity |

| Impact on Flavor | Mild flavor development | Significant flavor enhancement due to acid and alcohol production |

| Gas Production | Final rise from trapped carbon dioxide | Primary gas production stage |

Understanding Proofing and Fermentation in Baking

Proofing and fermentation are crucial processes in baking that impact dough texture and flavor development. Fermentation occurs as yeast consumes sugars, producing carbon dioxide and alcohol, which help dough rise and develop complex flavors over time. Proofing is the final rise after shaping, allowing the dough to expand further before baking, ensuring a light, airy crumb in the finished bread.

The Science Behind Proofing vs Fermentation

Proofing and fermentation are essential biochemical processes in baking that involve yeast metabolism and gas production. Fermentation refers to the initial stage where yeast converts sugars into carbon dioxide and alcohol, causing dough to rise and develop flavor. Proofing is the final rise after shaping, allowing yeast activity to create lightness and improve the bread's texture and volume before baking.

Key Differences Between Proofing and Fermentation

Proofing involves the final rise of dough before baking, primarily focusing on yeast activity to develop volume and texture, while fermentation encompasses the entire process where yeast and bacteria convert sugars into gases and acids, enhancing flavor and dough structure. During fermentation, gluten develops and complex flavors form over an extended period, whereas proofing is a shorter, controlled rest period that prepares dough for oven spring. Understanding these distinctions is crucial for bakers to optimize dough quality, texture, and taste in bread production.

Importance of Fermentation in Bread Quality

Fermentation plays a critical role in developing the flavor, texture, and aroma of bread by allowing yeast to convert sugars into carbon dioxide and alcohol, which leavens the dough and enriches its taste profile. This biological process also contributes to the dough's gluten network strengthening, resulting in improved crumb structure and moisture retention. Proper fermentation time and temperature control are essential for producing high-quality bread with a desirable rise and complex, well-rounded flavors.

The Role of Proofing in Dough Texture

Proofing plays a critical role in dough texture by allowing yeast to ferment the dough, producing carbon dioxide that creates air pockets and results in a light, airy crumb. During proofing, enzymes break down starches and proteins, enhancing flavor and improving dough elasticity. Proper proofing time and temperature ensure an optimal rise, contributing to a tender, well-structured final baked product.

Common Misconceptions: Proofing vs Fermentation

Proofing and fermentation are often confused, but they serve distinct roles in baking: fermentation is the yeast's process of breaking down sugars to develop flavor and dough structure, while proofing specifically refers to the final rise before baking. A common misconception is that proofing and fermentation are interchangeable, yet fermentation occurs throughout dough preparation, influencing crumb texture and taste. Understanding this distinction ensures bakers optimize timing and temperature to achieve ideal bread quality.

How Timing Affects Proofing and Fermentation

Timing plays a critical role in proofing and fermentation, directly impacting dough texture and flavor development. Extended fermentation allows yeast to produce more carbon dioxide and organic acids, resulting in enhanced aroma and a more complex taste profile. Overproofing, however, can cause weakened gluten structure, leading to poor oven spring and dense bread.

Tools and Techniques for Optimal Proofing and Fermentation

Optimal proofing and fermentation in bakery require precise temperature and humidity control, achieved with proofing cabinets and humidifiers designed to create ideal environments for yeast activity. Tools like digital thermometers and timers ensure accurate monitoring of dough temperature and fermentation duration, crucial for consistent gluten development and flavor profiles. Techniques such as using a controlled proofing box or covering dough with damp cloths help maintain moisture and avoid crust formation, maximizing yeast fermentation efficiency and dough rise.

Impact of Proofing and Fermentation on Flavor Development

Proofing and fermentation play crucial roles in flavor development in bakery products by influencing yeast activity and biochemical reactions. Fermentation allows yeast to convert sugars into alcohol and carbon dioxide over an extended period, enhancing complex flavor compounds such as organic acids and esters. Proofing, the final rise before baking, fine-tunes texture and aroma by enabling yeast to produce carbon dioxide and subtle byproducts that contribute to the bread's overall taste profile.

Best Practices for Bakery Business: Balancing Proofing and Fermentation

Balancing proofing and fermentation is crucial for bakery businesses to achieve optimal dough texture and flavor development. Best practices include controlling temperature and humidity precisely during proofing to allow yeast activation without overproofing, while managing fermentation times to enhance yeast activity and enzyme breakdown for richer taste and better crumb structure. Monitoring dough consistency and adjusting fermentation phases based on flour type and yeast strain ensures consistent product quality and enhances shelf life.

Proofing vs Fermentation Infographic

bizdif.com

bizdif.com