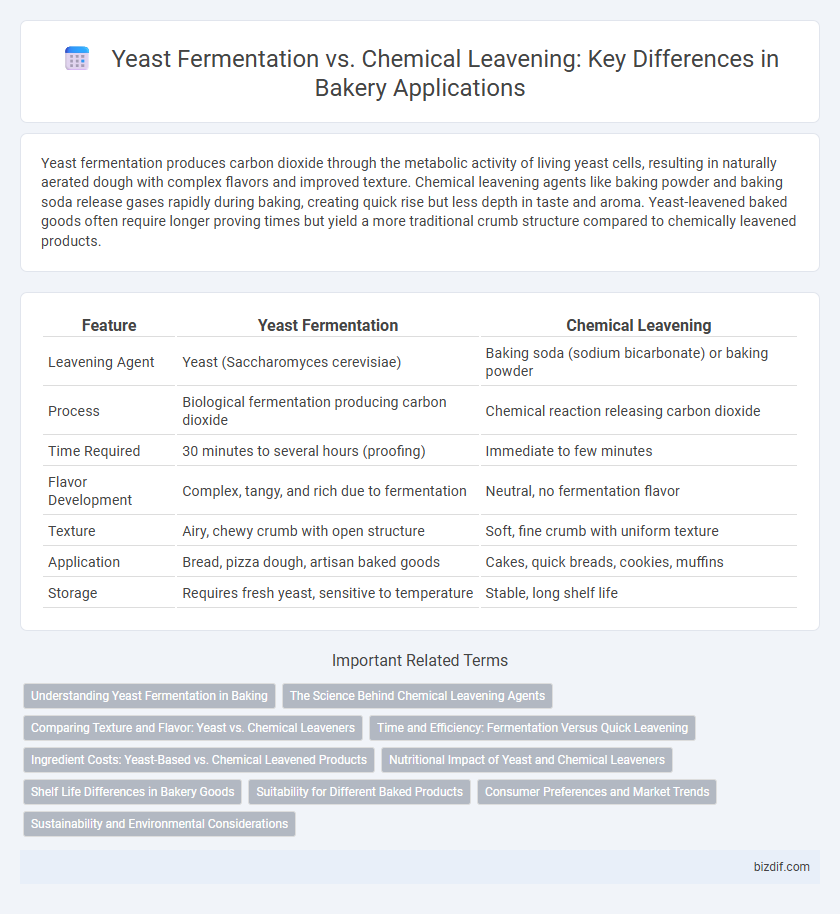

Yeast fermentation produces carbon dioxide through the metabolic activity of living yeast cells, resulting in naturally aerated dough with complex flavors and improved texture. Chemical leavening agents like baking powder and baking soda release gases rapidly during baking, creating quick rise but less depth in taste and aroma. Yeast-leavened baked goods often require longer proving times but yield a more traditional crumb structure compared to chemically leavened products.

Table of Comparison

| Feature | Yeast Fermentation | Chemical Leavening |

|---|---|---|

| Leavening Agent | Yeast (Saccharomyces cerevisiae) | Baking soda (sodium bicarbonate) or baking powder |

| Process | Biological fermentation producing carbon dioxide | Chemical reaction releasing carbon dioxide |

| Time Required | 30 minutes to several hours (proofing) | Immediate to few minutes |

| Flavor Development | Complex, tangy, and rich due to fermentation | Neutral, no fermentation flavor |

| Texture | Airy, chewy crumb with open structure | Soft, fine crumb with uniform texture |

| Application | Bread, pizza dough, artisan baked goods | Cakes, quick breads, cookies, muffins |

| Storage | Requires fresh yeast, sensitive to temperature | Stable, long shelf life |

Understanding Yeast Fermentation in Baking

Yeast fermentation in baking involves the metabolic process where yeast converts sugars into carbon dioxide and alcohol, causing dough to rise and develop complex flavors. This biological leavening method results in a soft crumb texture and enhanced aroma, essential for artisan breads and traditional pastries. Unlike chemical leavening agents such as baking soda or baking powder that produce quick gas release, yeast fermentation requires time but contributes to improved dough structure and nutritional profile.

The Science Behind Chemical Leavening Agents

Chemical leavening agents, such as baking powder and baking soda, produce carbon dioxide through acid-base reactions, causing dough to rise without requiring fermentation time. The release of gas bubbles during baking creates a light, porous crumb structure by expanding the dough internally. Unlike yeast fermentation, chemical leavening delivers immediate leavening action, essential for quick breads and cakes that do not undergo prolonged proofing.

Comparing Texture and Flavor: Yeast vs. Chemical Leaveners

Yeast fermentation produces a complex, airy texture with a slightly tangy flavor due to the natural fermentation process, enhancing the bread's depth and aroma. Chemical leaveners like baking powder and baking soda create a quicker rise, resulting in a softer, cake-like crumb with a neutral or slightly metallic taste. The choice between yeast and chemical leavening greatly influences the final product's texture and flavor profile, tailored to specific bakery items.

Time and Efficiency: Fermentation Versus Quick Leavening

Yeast fermentation requires several hours to produce carbon dioxide, resulting in slow dough rising that enhances flavor and texture through natural biochemical processes. Chemical leavening agents like baking powder and baking soda act rapidly, creating immediate gas bubbles that speed up baking time but provide less depth in taste development. Efficient bakery production often balances these methods to optimize time while maintaining desired quality in bread and pastries.

Ingredient Costs: Yeast-Based vs. Chemical Leavened Products

Yeast fermentation involves live microorganisms that require longer proofing times and stable environmental conditions, often leading to higher ingredient costs due to the need for fresh, active yeast and controlled fermentation processes. Chemical leavening agents like baking powder or baking soda typically incur lower upfront costs and faster production times, reducing labor and storage expenses. However, yeast-based products may justify higher costs by offering enhanced flavor complexity and texture, influencing consumer preference and pricing strategy.

Nutritional Impact of Yeast and Chemical Leaveners

Yeast fermentation enhances the nutritional profile of baked goods by breaking down starches and producing B vitamins, enzymes, and organic acids that improve digestion and nutrient absorption. Chemical leaveners like baking soda and baking powder provide rapid rise without contributing beneficial nutrients or improving bioavailability. Yeast-fermented breads often have lower glycemic indices and increased mineral availability compared to chemically leavened products.

Shelf Life Differences in Bakery Goods

Yeast fermentation produces natural gas bubbles that create a tender crumb and enhance flavor in bakery goods, often resulting in a longer shelf life due to the presence of organic acids and fermentation by-products that inhibit mold growth. Chemical leavening agents like baking powder or baking soda act quickly, providing immediate rise but lack the preservative effects of yeast, typically leading to a shorter shelf life and faster staling. The extended shelf life of yeast-leavened products makes them preferable for artisanal bread and rolls, while chemically leavened goods are ideal for quick baking with less emphasis on longevity.

Suitability for Different Baked Products

Yeast fermentation is ideal for bread and artisan products that benefit from longer rising times and complex flavor development, such as sourdough and brioche. Chemical leavening agents like baking powder and baking soda work best for quick breads, cakes, and muffins, providing rapid rise and tender crumb texture. Choosing the right leavening method depends on desired texture, flavor complexity, and baking time.

Consumer Preferences and Market Trends

Yeast fermentation remains favored by consumers seeking traditional bakery flavors and artisanal quality, contributing to its steady market demand. Chemical leavening agents like baking powder and baking soda cater to the growing preference for convenience and faster baking processes, driving innovation in ready-to-bake products. Market trends indicate a rising interest in natural and clean-label ingredients, boosting yeast fermentation's appeal among health-conscious consumers.

Sustainability and Environmental Considerations

Yeast fermentation in bakery processes offers a sustainable advantage by utilizing natural microorganisms that consume sugars and produce carbon dioxide, reducing reliance on synthetic chemicals. Chemical leavening agents like baking soda and baking powder often involve energy-intensive manufacturing and generate waste, contributing to a larger environmental footprint. Opting for yeast fermentation supports eco-friendly practices through lower emissions and biodegradable byproducts, aligning with green baking initiatives.

Yeast fermentation vs Chemical leavening Infographic

bizdif.com

bizdif.com