The melt pool in candle making refers to the liquid wax area surrounding the wick when the candle is lit, directly affecting the candle's burning performance and scent release. Hot throw describes the strength and quality of fragrance emitted by the candle while it is burning, which relies heavily on how well the fragrance oils disperse in the melt pool. Understanding the balance between a properly maintained melt pool and a strong hot throw is essential for creating candles that deliver consistent scent diffusion and optimal burning experience.

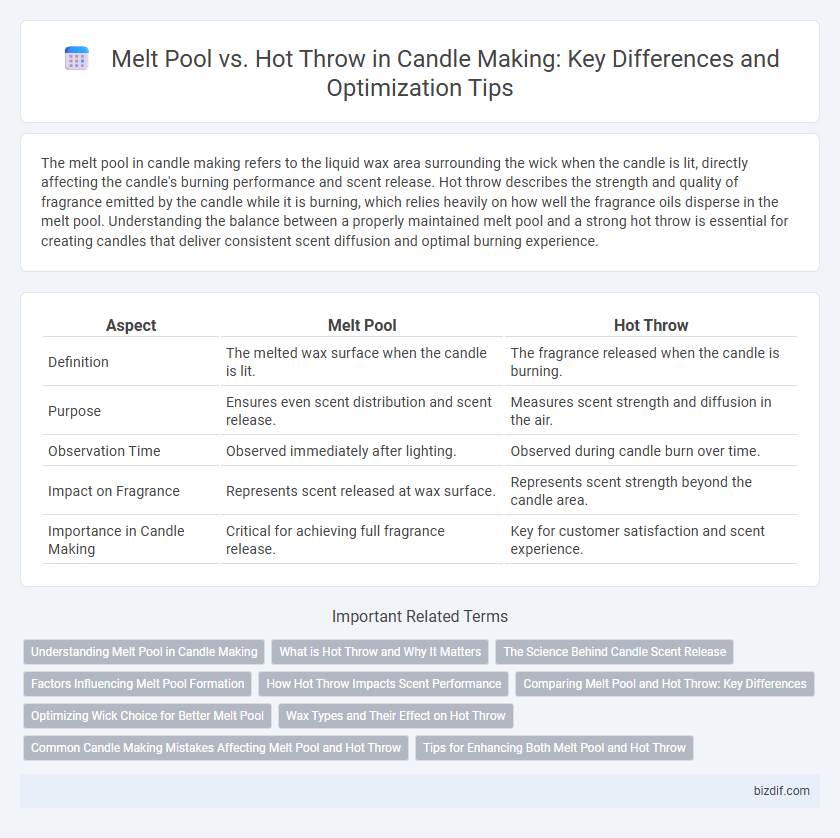

Table of Comparison

| Aspect | Melt Pool | Hot Throw |

|---|---|---|

| Definition | The melted wax surface when the candle is lit. | The fragrance released when the candle is burning. |

| Purpose | Ensures even scent distribution and scent release. | Measures scent strength and diffusion in the air. |

| Observation Time | Observed immediately after lighting. | Observed during candle burn over time. |

| Impact on Fragrance | Represents scent released at wax surface. | Represents scent strength beyond the candle area. |

| Importance in Candle Making | Critical for achieving full fragrance release. | Key for customer satisfaction and scent experience. |

Understanding Melt Pool in Candle Making

The melt pool in candle making refers to the liquid wax area that forms as the candle burns, critical for releasing the fragrance effectively. A properly maintained melt pool ensures even scent distribution and prevents tunneling, enhancing the candle's overall performance. Understanding and controlling the melt pool temperature and size directly impacts the candle's scent throw and burn quality.

What is Hot Throw and Why It Matters

Hot throw refers to the strength and quality of a candle's fragrance released when the candle is burning, directly influenced by the melt pool size and temperature. A well-formed melt pool ensures optimal scent diffusion, enhancing the hot throw by allowing the fragrance oils to vaporize evenly. Prioritizing hot throw is essential for candle makers to deliver a powerful and long-lasting aromatic experience to users.

The Science Behind Candle Scent Release

The melt pool in candle making refers to the liquid wax layer formed around the wick when a candle burns, which significantly influences the hot throw--the intensity of fragrance released while the candle is lit. The science behind candle scent release involves the diffusion of fragrance oils from the melt pool into the warmed air, where temperature and wax composition affect how volatile aromatic compounds evaporate. Optimizing the melt pool size and temperature enhances the hot throw by ensuring efficient scent dispersion without degrading fragrance molecules.

Factors Influencing Melt Pool Formation

Melt pool formation in candle making is influenced by wax type, fragrance oil concentration, and burning temperature, which collectively affect the candle's scent throw and overall burn quality. A well-formed melt pool ensures optimal hot throw by allowing fragrance molecules to evaporate efficiently without burning off prematurely. Variables such as wick size, container shape, and ambient conditions also play critical roles in maintaining a consistent melt pool for maximum fragrance release.

How Hot Throw Impacts Scent Performance

Hot throw significantly impacts scent performance by determining how well fragrance oils disperse when a candle is lit, influencing the overall aroma intensity in a room. Unlike the melt pool, which is the liquid wax area that releases scent slowly, hot throw activates the fragrance fully as heat volatilizes the oils. Optimizing hot throw through proper wax formula and fragrance load ensures a stronger, longer-lasting scent experience.

Comparing Melt Pool and Hot Throw: Key Differences

The melt pool refers to the liquid wax area around the wick during burning, directly impacting scent diffusion and candle performance. Hot throw describes the strength and reach of the fragrance released while the candle is lit. Unlike the melt pool's physical state affecting scent release, hot throw measures the intensity of fragrance perceived in the environment, highlighting their functional differences in candle making.

Optimizing Wick Choice for Better Melt Pool

Selecting the right wick is crucial to achieving an optimal melt pool in candle making, as it directly influences the burn temperature and wax melting rate. A properly sized wick ensures an even, larger melt pool, enhancing scent diffusion and maximizing hot throw performance. Choosing wicks based on candle diameter, wax type, and fragrance load improves combustion efficiency and scent throw consistency.

Wax Types and Their Effect on Hot Throw

Wax types significantly influence the melt pool's size and temperature, which directly impacts the hot throw in candle making. Natural waxes like soy and beeswax tend to produce cooler melt pools, resulting in a subtle but lingering fragrance release, while paraffin waxes create hotter, larger melt pools that amplify scent diffusion during burning. Understanding the interaction between wax composition and melt pool characteristics helps optimize fragrance dispersion and candle performance.

Common Candle Making Mistakes Affecting Melt Pool and Hot Throw

In candle making, improper wick sizing and uneven wax melting are common mistakes that negatively impact the melt pool and hot throw, reducing scent diffusion and burn quality. Using the wrong wax blend or adding fragrance oils beyond recommended percentages can lead to an insufficient melt pool and weak hot throw, causing uneven burning or scent throw issues. Ensuring proper wick choice, correct fragrance load, and optimal pouring temperature enhances melt pool performance and maximizes hot throw, delivering a consistent and strong fragrance release.

Tips for Enhancing Both Melt Pool and Hot Throw

Maximize your candle's melt pool by choosing a wax with a low melting point and using the correct wick size to ensure even melting. Enhance hot throw by increasing the fragrance load within recommended limits and allowing the candle to cure for at least two weeks before lighting. Maintaining optimal room temperature around 68-72degF during both curing and burning can significantly improve scent throw and melt pool performance.

Melt pool vs Hot throw Infographic

bizdif.com

bizdif.com