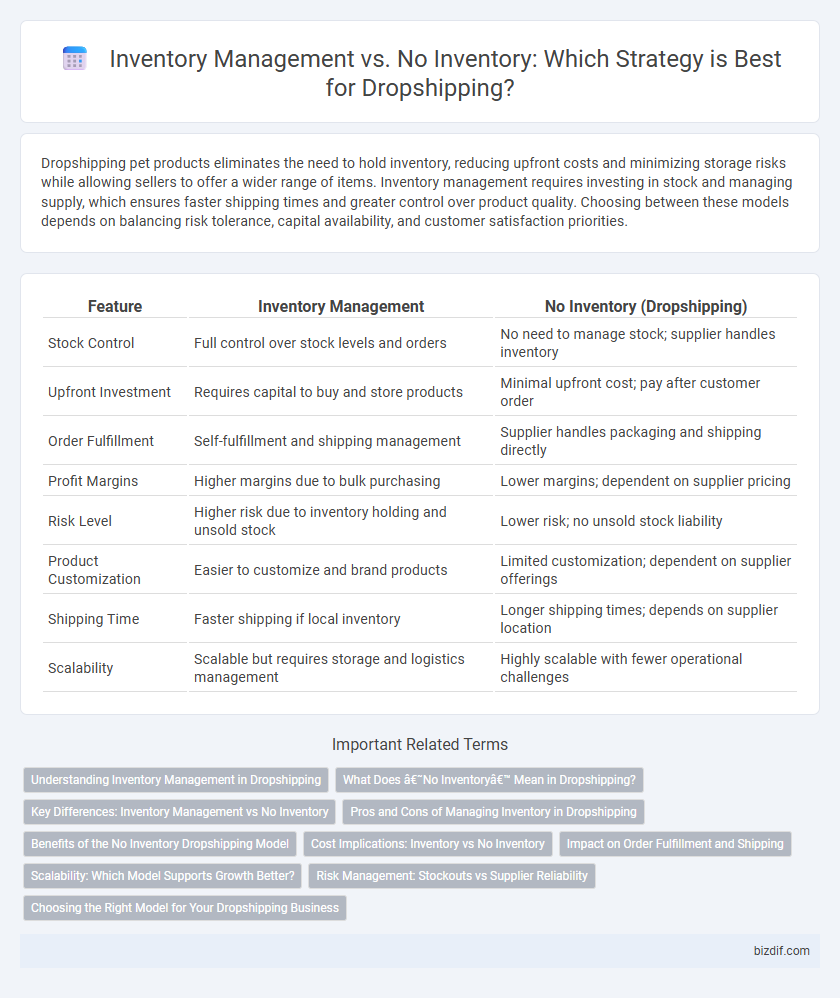

Dropshipping pet products eliminates the need to hold inventory, reducing upfront costs and minimizing storage risks while allowing sellers to offer a wider range of items. Inventory management requires investing in stock and managing supply, which ensures faster shipping times and greater control over product quality. Choosing between these models depends on balancing risk tolerance, capital availability, and customer satisfaction priorities.

Table of Comparison

| Feature | Inventory Management | No Inventory (Dropshipping) |

|---|---|---|

| Stock Control | Full control over stock levels and orders | No need to manage stock; supplier handles inventory |

| Upfront Investment | Requires capital to buy and store products | Minimal upfront cost; pay after customer order |

| Order Fulfillment | Self-fulfillment and shipping management | Supplier handles packaging and shipping directly |

| Profit Margins | Higher margins due to bulk purchasing | Lower margins; dependent on supplier pricing |

| Risk Level | Higher risk due to inventory holding and unsold stock | Lower risk; no unsold stock liability |

| Product Customization | Easier to customize and brand products | Limited customization; dependent on supplier offerings |

| Shipping Time | Faster shipping if local inventory | Longer shipping times; depends on supplier location |

| Scalability | Scalable but requires storage and logistics management | Highly scalable with fewer operational challenges |

Understanding Inventory Management in Dropshipping

Inventory management in dropshipping focuses on tracking stock levels, order fulfillment, and supplier communication without physically storing products, enabling real-time updates and reducing overhead costs. Unlike traditional inventory systems, dropshipping relies on seamless integration with suppliers' databases to maintain accurate product availability and prevent stockouts or overselling. Efficient inventory management software enhances automation, improves customer satisfaction, and optimizes supply chain operations by synchronizing orders directly with supplier inventory data.

What Does ‘No Inventory’ Mean in Dropshipping?

No inventory in dropshipping means that the retailer does not physically stock products; instead, they partner with suppliers who handle storage, packaging, and shipping directly to customers. This model reduces upfront costs and eliminates the risks associated with unsold stock, allowing businesses to scale quickly and focus on marketing and customer service. Inventory management, by contrast, requires maintaining stock levels, forecasting demand, and managing warehouse logistics, which can increase overhead and operational complexity.

Key Differences: Inventory Management vs No Inventory

Inventory management in dropshipping involves tracking stock levels, processing orders, and maintaining product availability, ensuring control over supply chain and minimizing stockouts. No inventory dropshipping relies entirely on suppliers to fulfill orders directly, eliminating the need for warehousing but reducing control over product quality and shipping times. Key differences include ownership of stock, risk exposure, and responsibility for inventory accuracy and order fulfillment.

Pros and Cons of Managing Inventory in Dropshipping

Managing inventory in dropshipping allows for greater control over stock levels, faster order fulfillment, and improved customer satisfaction by reducing backorder risks. However, it requires upfront investment in warehousing, increased operational complexity, and potential overstock issues that can tie up capital. In contrast, not holding inventory minimizes upfront costs and reduces risk but often leads to longer shipping times and less control over product availability.

Benefits of the No Inventory Dropshipping Model

The no inventory dropshipping model eliminates the need for upfront stock investment, reducing financial risk and storage costs for entrepreneurs. This approach allows businesses to offer a wide product range without managing physical inventory, enabling flexibility and scalability in response to market demand. By outsourcing order fulfillment to suppliers, sellers can focus on marketing and customer service, streamlining operations and accelerating growth.

Cost Implications: Inventory vs No Inventory

Maintaining inventory in dropshipping incurs costs such as warehousing, insurance, and potential obsolescence, which increase upfront expenses and financial risk. Choosing a no inventory model eliminates storage and holding costs, reducing capital investment but may result in higher per-unit prices and dependency on suppliers for fulfillment. Evaluating cost implications between inventory-based and inventory-free approaches is crucial for optimizing cash flow and profitability in dropshipping operations.

Impact on Order Fulfillment and Shipping

Dropshipping eliminates the need for inventory management, allowing merchants to focus solely on processing orders, which can lead to faster order fulfillment times depending on supplier efficiency. Managing inventory independently provides greater control over stock levels and reduces the risk of supplier delays, but requires investment in warehousing and increased operational complexity. The choice between dropshipping and holding inventory directly impacts shipping speed, with dropshipping relying heavily on third-party logistics, while in-house inventory enables potentially quicker dispatch and delivery control.

Scalability: Which Model Supports Growth Better?

Dropshipping offers greater scalability by eliminating the need for upfront inventory investment, allowing businesses to easily expand product offerings without the constraints of stock storage. In contrast, traditional inventory management requires significant capital and warehouse space, which can limit growth potential due to inventory risks and handling complexities. For rapid scaling, dropshipping supports flexible inventory sourcing and reduces financial barriers, making it the preferred model for businesses aiming to grow quickly.

Risk Management: Stockouts vs Supplier Reliability

Dropshipping eliminates stockout risks by transferring inventory management to suppliers, mitigating capital investment and overstock challenges. Relying heavily on supplier reliability is critical, as delays or errors directly impact order fulfillment and customer satisfaction. Effective risk management balances minimal inventory holding with stringent supplier vetting and contingency planning to ensure consistent product availability.

Choosing the Right Model for Your Dropshipping Business

Selecting the right model for your dropshipping business hinges on inventory management preferences: maintaining inventory offers greater control over stock levels, faster shipping times, and improved customer satisfaction, but requires upfront investment and storage costs. No inventory dropshipping reduces financial risk and overhead by relying on suppliers to handle stock and fulfillment, yet it may result in longer delivery times and potential stockouts. Analyzing factors such as budget, desired control, and customer experience helps determine the optimal approach for scaling your dropshipping operations effectively.

Inventory Management vs No Inventory Infographic

bizdif.com

bizdif.com