Reverse logistics in dropshipping pet products involves managing returns, exchanges, and recycling of items, ensuring customer satisfaction and sustainability. Forward logistics focuses on the efficient movement of pet supplies from suppliers to customers, optimizing order fulfillment and delivery times. Balancing both logistics processes enhances the overall supply chain efficiency and customer experience in the dropshipping pet industry.

Table of Comparison

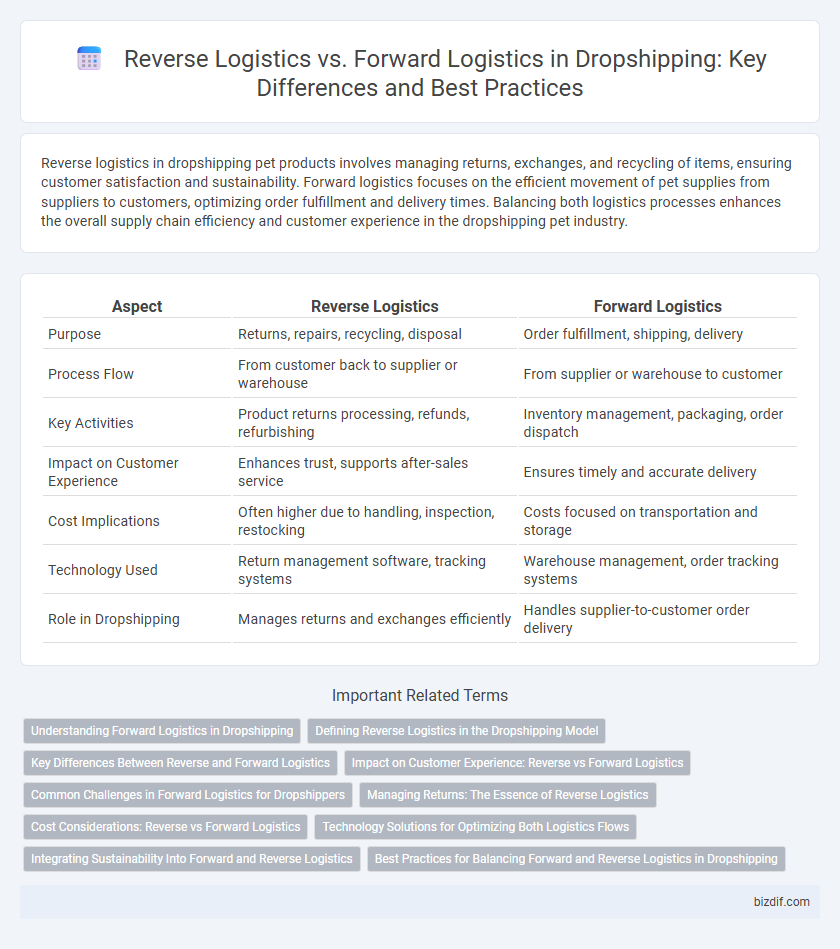

| Aspect | Reverse Logistics | Forward Logistics |

|---|---|---|

| Purpose | Returns, repairs, recycling, disposal | Order fulfillment, shipping, delivery |

| Process Flow | From customer back to supplier or warehouse | From supplier or warehouse to customer |

| Key Activities | Product returns processing, refunds, refurbishing | Inventory management, packaging, order dispatch |

| Impact on Customer Experience | Enhances trust, supports after-sales service | Ensures timely and accurate delivery |

| Cost Implications | Often higher due to handling, inspection, restocking | Costs focused on transportation and storage |

| Technology Used | Return management software, tracking systems | Warehouse management, order tracking systems |

| Role in Dropshipping | Manages returns and exchanges efficiently | Handles supplier-to-customer order delivery |

Understanding Forward Logistics in Dropshipping

Forward logistics in dropshipping involves the process of moving products from suppliers directly to customers, emphasizing order fulfillment efficiency and timely delivery. Key components include inventory management, packaging, shipping, and real-time tracking to ensure customer satisfaction and reduce delivery times. Streamlined forward logistics enhances competitive advantage by minimizing shipping errors and enabling faster order processing in the dropshipping supply chain.

Defining Reverse Logistics in the Dropshipping Model

Reverse logistics in the dropshipping model involves managing product returns, exchanges, and refunds directly between customers and suppliers, ensuring efficient handling without holding inventory. This process contrasts with forward logistics, which focuses on order fulfillment and delivery from suppliers to customers. Effective reverse logistics enhances customer satisfaction and reduces operational costs by streamlining return procedures within the dropshipping ecosystem.

Key Differences Between Reverse and Forward Logistics

Reverse logistics involves the process of returning products from customers back to the seller or manufacturer for refunds, repairs, or recycling, while forward logistics focuses on the movement of goods from suppliers to customers. Key differences include the direction of product flow, with reverse logistics handling returns and forward logistics managing initial deliveries. Reverse logistics requires efficient handling of returns management, product disposition, and recovery, contrasting with forward logistics' emphasis on inventory management, order fulfillment, and distribution efficiency.

Impact on Customer Experience: Reverse vs Forward Logistics

Forward logistics ensures timely delivery of products, enhancing customer satisfaction through reliable order fulfillment and efficient shipping processes. Reverse logistics directly affects customer experience by managing returns, exchanges, and refunds smoothly, fostering trust and encouraging repeat purchases. Optimizing both logistics flows minimizes delays and complications, resulting in a seamless overall customer journey in dropshipping operations.

Common Challenges in Forward Logistics for Dropshippers

Forward logistics in dropshipping commonly faces challenges such as inventory inaccuracies, shipment delays, and insufficient tracking visibility. Miscommunication between suppliers and fulfillment centers often leads to order fulfillment errors, impacting customer satisfaction. Managing multiple carriers and varying shipping policies further complicates maintaining consistent delivery times and service quality.

Managing Returns: The Essence of Reverse Logistics

Managing returns in dropshipping demands an efficient reverse logistics strategy to handle product recalls, exchanges, and refunds promptly. Reverse logistics optimizes inventory recovery and reduces costs by streamlining the return process and enhancing customer satisfaction. Forward logistics focuses on order fulfillment and delivery, while reverse logistics ensures seamless return management, boosting overall supply chain resilience.

Cost Considerations: Reverse vs Forward Logistics

Reverse logistics in dropshipping often incurs higher costs than forward logistics due to expenses related to returns processing, inspection, restocking, and potential refurbishment. Forward logistics primarily involves shipping products directly from suppliers to customers, minimizing handling and reducing transportation costs. Efficient management of reverse logistics is critical to controlling losses and maintaining profitability in dropshipping operations.

Technology Solutions for Optimizing Both Logistics Flows

Technology solutions such as AI-powered inventory management systems and real-time tracking platforms optimize both reverse and forward logistics by enhancing transparency and efficiency in dropshipping operations. Advanced analytics tools predict return patterns and streamline reverse logistics processes, reducing costs and improving customer satisfaction. Integration of automated warehouse systems and IoT devices ensures seamless coordination between shipments and returns, maximizing overall supply chain performance.

Integrating Sustainability Into Forward and Reverse Logistics

Integrating sustainability into forward and reverse logistics is crucial for optimizing dropshipping operations by reducing environmental impacts and improving resource efficiency. Forward logistics focuses on sustainable packaging, energy-efficient transportation, and minimizing carbon footprints during product delivery, while reverse logistics emphasizes eco-friendly returns management, recycling, and waste reduction. Combining sustainable practices in both logistics flows enhances supply chain resilience and supports corporate social responsibility goals in dropshipping businesses.

Best Practices for Balancing Forward and Reverse Logistics in Dropshipping

Efficient dropshipping operations require seamless integration of forward logistics, which ensures timely delivery of products from suppliers to customers, with reverse logistics that manages returns and exchanges effectively. Best practices include investing in robust inventory tracking systems, clear return policies, and collaborating closely with reliable carriers to minimize delays and costs. Prioritizing transparency and communication enhances customer satisfaction while maintaining profitability in both shipping directions.

Reverse Logistics vs Forward Logistics Infographic

bizdif.com

bizdif.com