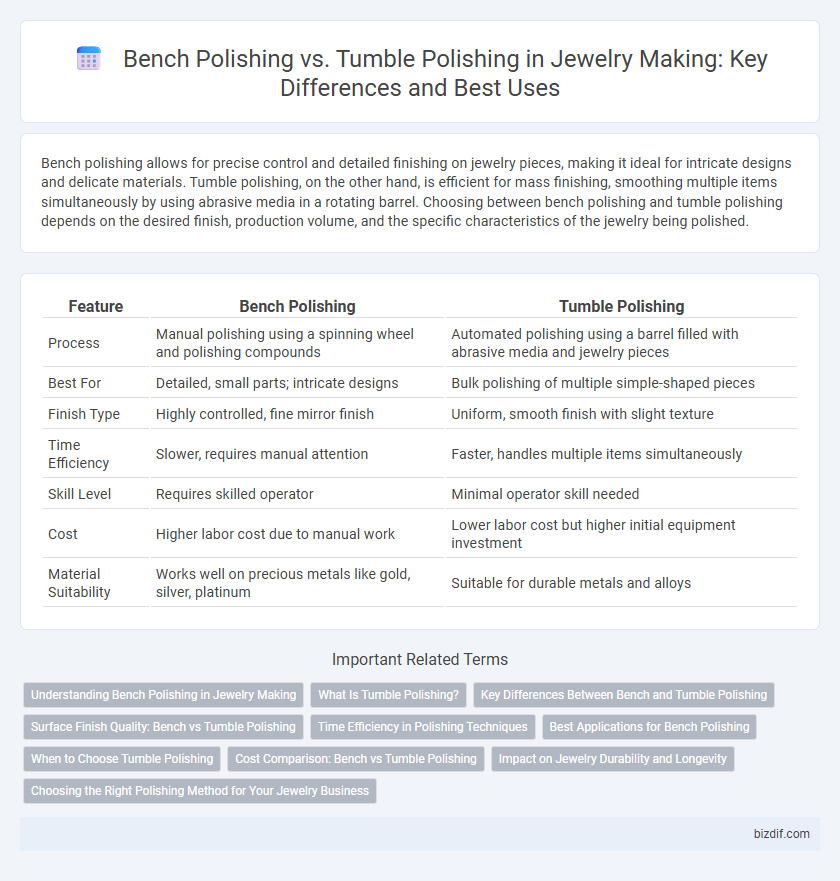

Bench polishing allows for precise control and detailed finishing on jewelry pieces, making it ideal for intricate designs and delicate materials. Tumble polishing, on the other hand, is efficient for mass finishing, smoothing multiple items simultaneously by using abrasive media in a rotating barrel. Choosing between bench polishing and tumble polishing depends on the desired finish, production volume, and the specific characteristics of the jewelry being polished.

Table of Comparison

| Feature | Bench Polishing | Tumble Polishing |

|---|---|---|

| Process | Manual polishing using a spinning wheel and polishing compounds | Automated polishing using a barrel filled with abrasive media and jewelry pieces |

| Best For | Detailed, small parts; intricate designs | Bulk polishing of multiple simple-shaped pieces |

| Finish Type | Highly controlled, fine mirror finish | Uniform, smooth finish with slight texture |

| Time Efficiency | Slower, requires manual attention | Faster, handles multiple items simultaneously |

| Skill Level | Requires skilled operator | Minimal operator skill needed |

| Cost | Higher labor cost due to manual work | Lower labor cost but higher initial equipment investment |

| Material Suitability | Works well on precious metals like gold, silver, platinum | Suitable for durable metals and alloys |

Understanding Bench Polishing in Jewelry Making

Bench polishing in jewelry making involves manually refining and shining pieces using a rotating wheel or buffing machine, allowing artisans precise control over the finish. This technique is essential for intricate designs and delicate components, ensuring a high-quality, detailed polish that highlights craftsmanship. Compared to tumble polishing, bench polishing targets specific areas and achieves a smoother, more refined surface ideal for luxury jewelry.

What Is Tumble Polishing?

Tumble polishing is a technique used in jewelry making that involves placing metal pieces in a rotating barrel filled with abrasive media and water to smooth and shine surfaces through friction. This method is particularly effective for polishing small, irregularly shaped items and removing surface imperfections quickly and uniformly. Compared to bench polishing, tumble polishing streamlines the finishing process by automating surface smoothing while maintaining consistent quality on multiple pieces simultaneously.

Key Differences Between Bench and Tumble Polishing

Bench polishing involves manually buffing jewelry pieces using polishing wheels or cloths, allowing precise control over specific areas and intricate designs. Tumble polishing uses a rotating barrel filled with abrasive media to polish multiple items simultaneously, providing a more uniform finish but less detailed precision. Key differences include the level of control, suitability for complex shapes, and batch processing efficiency.

Surface Finish Quality: Bench vs Tumble Polishing

Bench polishing delivers a superior surface finish with precise control, allowing jewelers to target intricate details and achieve a high-gloss shine ideal for fine jewelry pieces. Tumble polishing efficiently processes multiple items simultaneously, producing a uniform, smooth surface but may lack the refined detail achievable with bench methods. Choosing between these techniques depends on desired surface finish quality, complexity of design, and production volume requirements.

Time Efficiency in Polishing Techniques

Bench polishing offers greater time efficiency for intricate jewelry pieces due to precise hand control, allowing for targeted polishing and quicker touch-ups. Tumble polishing suits bulk processing, rapidly smoothing multiple items simultaneously, but requires longer cycles to achieve uniform shine. Choosing between these methods depends on the piece complexity and production volume, balancing speed with finish quality.

Best Applications for Bench Polishing

Bench polishing is ideal for detailed jewelry pieces requiring precise control and a high-gloss finish, such as intricate rings, pendants, and custom designs. It excels in refining edges, restoring metal surfaces, and polishing delicate gemstones where abrasive tumbling might cause damage. This method is preferred for small-scale, artisanal projects demanding meticulous craftsmanship and surface smoothness.

When to Choose Tumble Polishing

Tumble polishing is ideal for small, durable jewelry pieces with intricate details that require uniform smoothing and deburring. This method efficiently polishes multiple items simultaneously, saving time and labor compared to bench polishing. Choose tumble polishing for bulk treatments of items like chains, beads, and cast components that can withstand the mechanical action without damage.

Cost Comparison: Bench vs Tumble Polishing

Bench polishing involves manual labor and specialized equipment, making it more expensive upfront but ideal for detailed, custom jewelry pieces. Tumble polishing uses a rotary barrel filled with abrasive media, offering a cost-effective solution for bulk polishing with minimal labor investment. The cost comparison reveals bench polishing has higher variable costs due to skilled labor, while tumble polishing provides lower per-piece expenses in large-scale production.

Impact on Jewelry Durability and Longevity

Bench polishing uses precise, manual techniques with polishing wheels and compounds, allowing skilled artisans to carefully control the finish without compromising the jewelry's structural integrity. Tumble polishing involves placing jewelry pieces in a rotating barrel with abrasive media, which can smooth surfaces quickly but risks wearing down fine details and thinning delicate components over time. Jewelry durability and longevity are generally better preserved with bench polishing due to its targeted approach, while tumble polishing may be suitable for more robust, less intricate pieces.

Choosing the Right Polishing Method for Your Jewelry Business

Bench polishing offers precise control and is ideal for delicate or intricate jewelry pieces requiring detailed finishing, while tumble polishing excels in efficiently smoothing large batches of durable items by using abrasive media in a rotating barrel. Selecting the optimal polishing method depends on factors such as jewelry material, production volume, desired surface finish, and turnaround time. Integrating both techniques strategically can enhance product quality and operational efficiency in a jewelry business.

Bench polishing vs tumble polishing Infographic

bizdif.com

bizdif.com