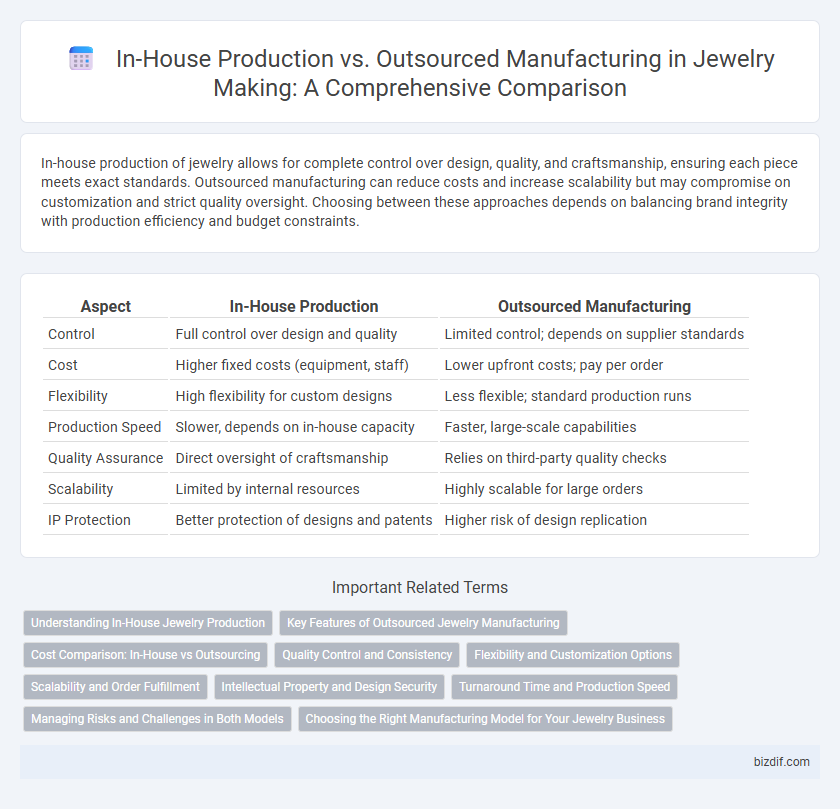

In-house production of jewelry allows for complete control over design, quality, and craftsmanship, ensuring each piece meets exact standards. Outsourced manufacturing can reduce costs and increase scalability but may compromise on customization and strict quality oversight. Choosing between these approaches depends on balancing brand integrity with production efficiency and budget constraints.

Table of Comparison

| Aspect | In-House Production | Outsourced Manufacturing |

|---|---|---|

| Control | Full control over design and quality | Limited control; depends on supplier standards |

| Cost | Higher fixed costs (equipment, staff) | Lower upfront costs; pay per order |

| Flexibility | High flexibility for custom designs | Less flexible; standard production runs |

| Production Speed | Slower, depends on in-house capacity | Faster, large-scale capabilities |

| Quality Assurance | Direct oversight of craftsmanship | Relies on third-party quality checks |

| Scalability | Limited by internal resources | Highly scalable for large orders |

| IP Protection | Better protection of designs and patents | Higher risk of design replication |

Understanding In-House Jewelry Production

In-house jewelry production offers complete control over every step of the crafting process, ensuring superior quality and precision in design execution. It allows artisans to customize pieces extensively and respond quickly to market trends or customer demands. Managing production internally also reduces dependency on external suppliers, streamlining lead times and protecting proprietary techniques or unique design elements.

Key Features of Outsourced Jewelry Manufacturing

Outsourced jewelry manufacturing offers specialized expertise, advanced technology, and scalability that in-house production may lack. It enables access to a broad range of materials and skilled artisans, reducing overhead costs and lead times. Quality control and customizable services are often integrated, ensuring consistent product standards and flexibility for evolving designs.

Cost Comparison: In-House vs Outsourcing

In-house jewelry production often involves higher fixed costs due to equipment investment, skilled labor salaries, and workspace maintenance, but it allows for greater control over quality and customization. Outsourced manufacturing typically offers lower upfront expenses and scalability by leveraging external suppliers' economies of scale, though it may introduce variable costs related to shipping, tariffs, and communication overhead. Evaluating total cost of ownership requires analyzing direct expenses, indirect risks, and long-term value alignment with brand identity and market demand.

Quality Control and Consistency

In-house production ensures superior quality control by allowing jewelers to monitor every stage of the crafting process, resulting in consistent and finely detailed pieces. Outsourced manufacturing may introduce variability due to differing production standards and less direct oversight, potentially affecting the uniformity of jewelry collections. Maintaining stringent quality checks in-house enhances brand reputation through reliable product consistency and craftsmanship excellence.

Flexibility and Customization Options

In-house production in jewelry making offers superior flexibility and extensive customization options, allowing designers to experiment with unique materials and intricate details quickly. Outsourced manufacturing, while often cost-effective, can limit the ability to modify designs on short notice and restrict personalized craftsmanship. Choosing in-house production enhances creative control and responsiveness, which is essential for bespoke and limited-edition jewelry pieces.

Scalability and Order Fulfillment

In-house production allows for greater control over scalability and order fulfillment, enabling jewelry makers to quickly adjust manufacturing volume in response to demand fluctuations. Outsourced manufacturing offers the advantage of handling large-scale orders without the need for significant capital investment in equipment or labor. Efficient order fulfillment relies on balancing production capacity with supply chain reliability to minimize lead times and maintain product quality.

Intellectual Property and Design Security

In-house production in jewelry making ensures maximum control over intellectual property and design security by limiting external access to proprietary designs and techniques. Outsourced manufacturing poses risks of unauthorized replication or design theft due to shared knowledge with third-party vendors. Protecting unique craftsmanship and maintaining confidentiality is more effective when production remains within the company's secured environment.

Turnaround Time and Production Speed

In-house jewelry production offers faster turnaround times due to direct control over the manufacturing process, enabling quick adjustments and immediate quality checks. Outsourced manufacturing often involves longer lead times because of shipping delays and coordination with third-party vendors. Prioritizing production speed, in-house workshops streamline workflows with specialized equipment and skilled artisans, while outsourced partners may sacrifice speed for cost efficiency.

Managing Risks and Challenges in Both Models

Managing risks in in-house jewelry production involves direct oversight of craftsmanship quality and supply chain control, reducing delays but increasing fixed costs and labor challenges. Outsourced manufacturing mitigates operational overhead and leverages specialized expertise but introduces risks such as inconsistent quality, intellectual property concerns, and longer communication cycles. Implementing rigorous vendor vetting, maintaining transparent communication, and employing quality assurance protocols are essential to address challenges in both production models effectively.

Choosing the Right Manufacturing Model for Your Jewelry Business

Selecting the ideal manufacturing model for your jewelry business hinges on factors like cost control, quality assurance, and production scalability. In-house production offers direct oversight and customization capabilities, fostering brand consistency and faster prototyping, while outsourced manufacturing provides access to specialized expertise and reduced operational expenses. Balancing these advantages with your business priorities ensures efficient workflow, optimal resource allocation, and enhanced product quality in your jewelry line.

In-house production vs Outsourced manufacturing Infographic

bizdif.com

bizdif.com