Soldering in jewelry making involves melting a filler metal to join pieces, providing strong and durable bonds ideal for larger connections but may cause heat distortion on delicate parts. Laser welding offers precise, localized heat application, enabling seamless repairs and intricate joins without affecting surrounding materials, making it perfect for fine or complex designs. Choosing between soldering and laser welding depends on the jewelry's size, detail, and the need for heat-sensitive handling.

Table of Comparison

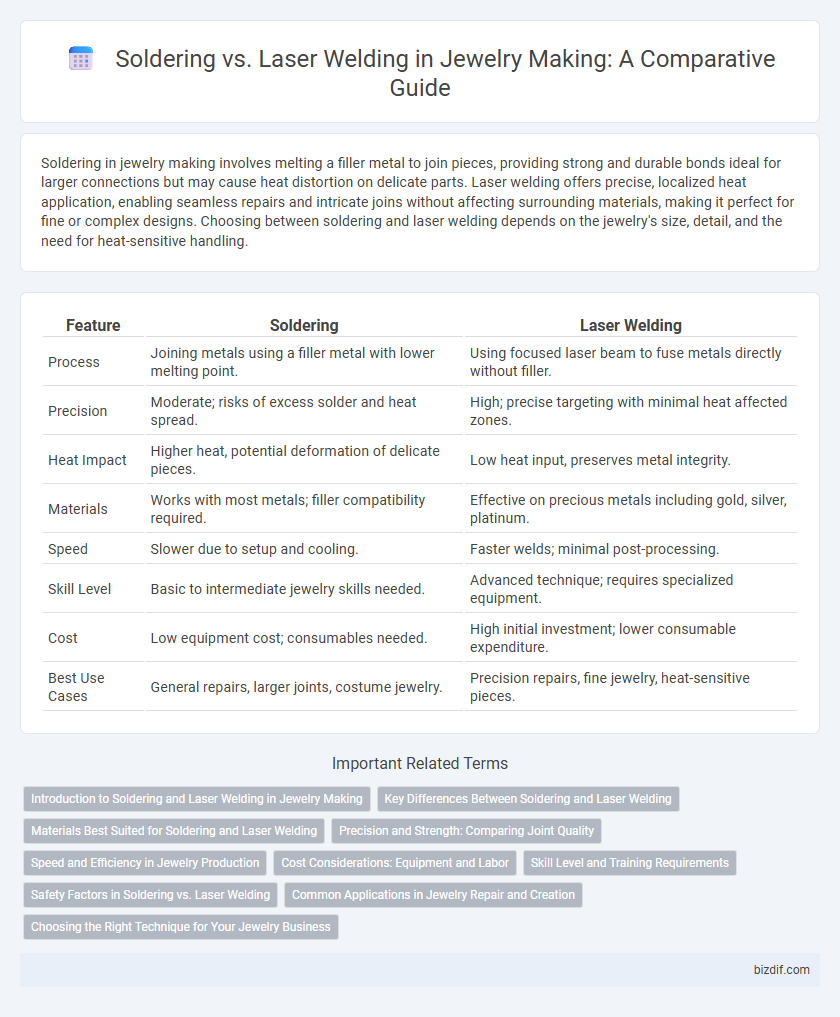

| Feature | Soldering | Laser Welding |

|---|---|---|

| Process | Joining metals using a filler metal with lower melting point. | Using focused laser beam to fuse metals directly without filler. |

| Precision | Moderate; risks of excess solder and heat spread. | High; precise targeting with minimal heat affected zones. |

| Heat Impact | Higher heat, potential deformation of delicate pieces. | Low heat input, preserves metal integrity. |

| Materials | Works with most metals; filler compatibility required. | Effective on precious metals including gold, silver, platinum. |

| Speed | Slower due to setup and cooling. | Faster welds; minimal post-processing. |

| Skill Level | Basic to intermediate jewelry skills needed. | Advanced technique; requires specialized equipment. |

| Cost | Low equipment cost; consumables needed. | High initial investment; lower consumable expenditure. |

| Best Use Cases | General repairs, larger joints, costume jewelry. | Precision repairs, fine jewelry, heat-sensitive pieces. |

Introduction to Soldering and Laser Welding in Jewelry Making

Soldering in jewelry making involves joining metal pieces using a filler metal with a lower melting point, creating strong, lasting bonds ideal for intricate designs and repairs. Laser welding uses concentrated light beams to fuse metals with extreme precision, allowing for minimal heat impact and fine detail work in delicate pieces. Both techniques enhance the craftsmanship and durability of jewelry, with soldering excelling in traditional applications and laser welding offering advanced, precise repair solutions.

Key Differences Between Soldering and Laser Welding

Soldering uses a filler metal with a lower melting point to join jewelry pieces, creating a strong bond without melting the base metals; laser welding uses a focused laser beam to melt and fuse the metals directly, allowing for precise, clean joints and minimal heat impact. Soldering is ideal for simpler repairs and assembly, while laser welding excels in delicate work, intricate designs, and repairing hard-to-reach areas with minimal distortion. Laser welding offers superior strength and durability in the joint compared to soldered connections, making it preferred for high-end or detailed jewelry fabrication.

Materials Best Suited for Soldering and Laser Welding

Soldering is best suited for joining precious metals such as gold, silver, and copper alloys, where heat-sensitive stones or delicate components require minimal thermal exposure. Laser welding excels with a wider range of materials, including stainless steel, titanium, and mixed-metal assemblies, offering precise control and reducing the risk of heat damage. Both techniques are essential for jewelry making, but laser welding is favored for complex repairs and intricate designs involving hard-to-solder metals.

Precision and Strength: Comparing Joint Quality

Laser welding offers superior precision by targeting tiny areas without affecting surrounding metal, resulting in minimal heat distortion and clean, strong joints ideal for delicate jewelry designs. Soldering, while effective for general assembly, applies broader heat that can weaken nearby components and produce less precise joints. The high-quality, durable connections achieved through laser welding enhance the longevity and fine detailing of intricate jewelry pieces.

Speed and Efficiency in Jewelry Production

Laser welding offers superior speed and precision in jewelry production by creating strong, focused joints with minimal heat distortion, significantly reducing the risk of damage to delicate pieces. Traditional soldering requires longer heating times and careful temperature control, which can slow down production and affect the integrity of intricate designs. Jewelry manufacturers prioritize laser welding for its faster turnaround times and enhanced efficiency, increasing overall productivity without sacrificing quality.

Cost Considerations: Equipment and Labor

Soldering typically requires lower upfront equipment costs, utilizing basic torches and solder materials, making it more accessible for small-scale jewelry makers. Laser welding involves a higher initial investment in specialized laser machines but offers precise and efficient joint creation, reducing labor time and potential errors. While labor costs may be higher initially for laser welding due to operator training, the long-term savings from speed and accuracy can offset equipment expenses.

Skill Level and Training Requirements

Soldering in jewelry making requires moderate skill and foundational training, ideal for creating reliable joints on various metals with traditional methods. Laser welding demands advanced expertise and specialized training due to its precision and the need to operate sophisticated equipment safely. Investing in skill development for laser welding can significantly enhance craftsmanship and allow for intricate repairs that soldering cannot achieve.

Safety Factors in Soldering vs. Laser Welding

Soldering in jewelry making involves open flames and molten metals, posing risks of burns, inhalation of toxic fumes, and fire hazards, which require proper ventilation and protective gear. Laser welding offers a safer alternative by using a focused light beam that minimizes heat exposure and eliminates open flames, reducing the risk of burns and hazardous fumes. Both methods demand eye protection; however, laser welding necessitates specialized protective eyewear to shield against laser radiation.

Common Applications in Jewelry Repair and Creation

Soldering is widely used in jewelry repair for joining precious metals like gold and silver, creating strong, seamless connections ideal for resizing rings and attaching clasps. Laser welding offers precision and minimal thermal impact, making it perfect for delicate repairs on gemstones and intricate designs without damaging heat-sensitive components. Both techniques are essential in jewelry creation, with soldering suited for structural assembly and laser welding preferred for fine detailing and conservation of original finishes.

Choosing the Right Technique for Your Jewelry Business

Soldering remains a reliable and cost-effective technique for traditional jewelry making, ideal for pieces with thick joints and base metals like silver or gold alloys. Laser welding offers precision and minimal heat impact, making it perfect for repairing delicate or intricate designs, especially with precious metals such as platinum and white gold. Selecting between soldering and laser welding depends on factors like metal type, design complexity, and production volume, ensuring efficiency and quality in your jewelry business.

Soldering vs Laser welding Infographic

bizdif.com

bizdif.com