Benchwork in jewelry making involves hands-on techniques like sawing, filing, soldering, and stone setting, allowing artisans to create highly detailed and customizable pieces. Casting, on the other hand, uses molds and molten metal to produce multiple identical items efficiently, often ideal for mass production. Choosing between benchwork and casting depends on the desired intricacy, volume, and uniqueness of the jewelry design.

Table of Comparison

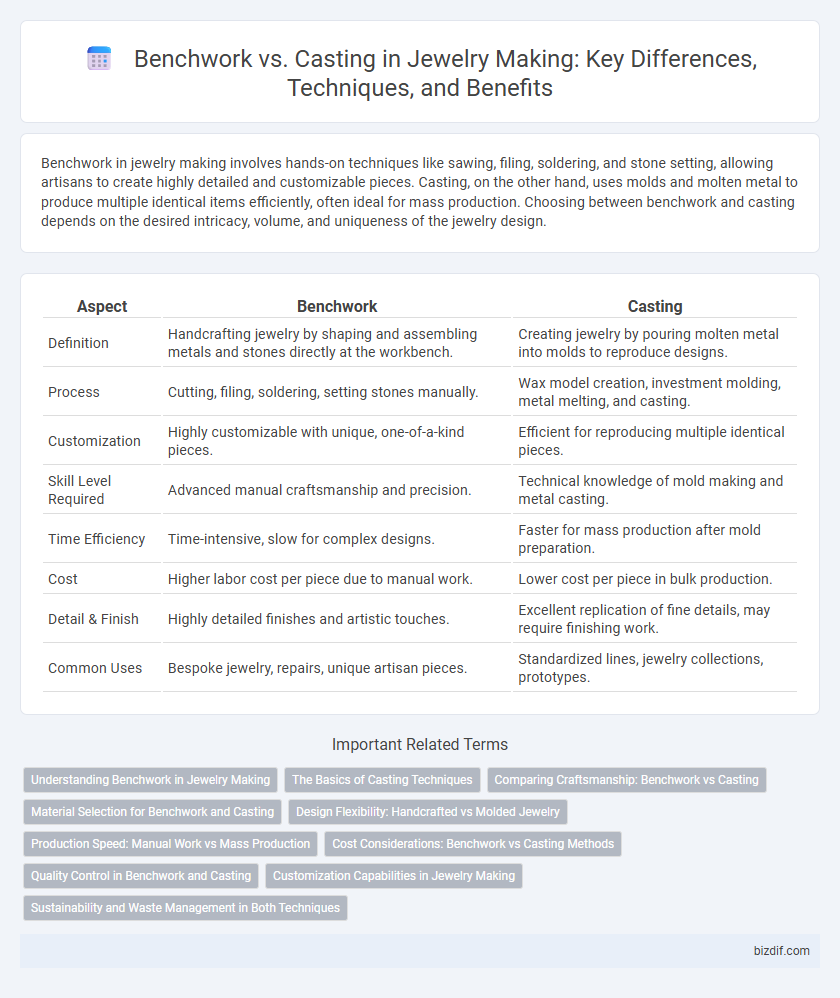

| Aspect | Benchwork | Casting |

|---|---|---|

| Definition | Handcrafting jewelry by shaping and assembling metals and stones directly at the workbench. | Creating jewelry by pouring molten metal into molds to reproduce designs. |

| Process | Cutting, filing, soldering, setting stones manually. | Wax model creation, investment molding, metal melting, and casting. |

| Customization | Highly customizable with unique, one-of-a-kind pieces. | Efficient for reproducing multiple identical pieces. |

| Skill Level Required | Advanced manual craftsmanship and precision. | Technical knowledge of mold making and metal casting. |

| Time Efficiency | Time-intensive, slow for complex designs. | Faster for mass production after mold preparation. |

| Cost | Higher labor cost per piece due to manual work. | Lower cost per piece in bulk production. |

| Detail & Finish | Highly detailed finishes and artistic touches. | Excellent replication of fine details, may require finishing work. |

| Common Uses | Bespoke jewelry, repairs, unique artisan pieces. | Standardized lines, jewelry collections, prototypes. |

Understanding Benchwork in Jewelry Making

Benchwork in jewelry making involves hands-on techniques such as sawing, filing, soldering, and stone setting, allowing artisans precise control over each detail. This method emphasizes craftsmanship and customization, enabling jewelers to create unique, intricate designs directly at the workbench. Mastery of benchwork skills is fundamental for achieving high-quality finishes and personalized artistry in fine jewelry production.

The Basics of Casting Techniques

Casting techniques in jewelry making involve creating a mold from a model to reproduce intricate designs with precision, commonly using methods such as lost-wax casting. This process allows for high-detail replication by melting precious metals like gold, silver, or platinum into the mold, which is ideal for producing complex shapes that are difficult to achieve with traditional benchwork. Mastery of casting basics enhances efficiency and quality in generating consistent, reproducible jewelry pieces.

Comparing Craftsmanship: Benchwork vs Casting

Benchwork in jewelry making emphasizes handcrafted precision, allowing artisans to shape, file, and assemble pieces with intricate detail and personalized artistic touches. Casting leverages mold-based processes to replicate designs efficiently, ideal for producing consistent, complex shapes in larger quantities. The craftsmanship in benchwork showcases individual skill and customization, while casting prioritizes uniformity and scalability in jewelry production.

Material Selection for Benchwork and Casting

Material selection for benchwork emphasizes malleable metals like sterling silver, gold, and copper, which respond well to hand tools and soldering techniques. Casting requires materials with specific melting points and flow characteristics, such as investment casting waxes, sterling silver, gold alloys, and bronze, to achieve precise mold replication. Choosing the right metal directly affects the quality, detail, and durability of the final jewelry piece in both processes.

Design Flexibility: Handcrafted vs Molded Jewelry

Benchwork in jewelry making offers unmatched design flexibility by allowing artisans to create intricate, one-of-a-kind pieces through handcrafting techniques, enabling personalized adjustments and unique textures. In contrast, casting relies on molds to replicate designs, making it ideal for producing consistent, detailed jewelry in larger quantities but limiting customization. Handcrafted jewelry showcases the artisan's skill and creativity, while molded pieces emphasize precision and repeatability in design.

Production Speed: Manual Work vs Mass Production

Benchwork in jewelry making involves meticulous manual craftsmanship, offering flexibility and precision but limited production speed, ideal for custom or small-batch pieces. Casting techniques utilize molds to replicate designs rapidly, significantly accelerating mass production and enabling high-volume output with consistent quality. Choosing between benchwork and casting hinges on the desired balance between artisanal detail and efficient scalability in jewelry manufacturing.

Cost Considerations: Benchwork vs Casting Methods

Benchwork jewelry making typically incurs lower upfront costs as it primarily requires hand tools and basic equipment, making it ideal for small-scale or custom pieces. Casting methods involve higher initial expenses due to investment in molds, casting machines, and specialized materials, but they offer cost efficiency for mass production. Evaluating cost considerations between benchwork and casting depends on production volume, complexity, and desired finish quality.

Quality Control in Benchwork and Casting

Benchwork in jewelry making allows for meticulous quality control through direct artisan involvement, ensuring precision in detailing, symmetry, and finish. Casting offers consistent replication of designs but requires rigorous mold inspection and metal flow monitoring to prevent defects like porosity or incomplete fills. Combining benchwork's hands-on adjustments with casting's reproducibility enhances overall jewelry quality and durability.

Customization Capabilities in Jewelry Making

Benchwork in jewelry making offers superior customization capabilities by allowing artisans to handcraft unique details and make real-time adjustments during the creation process. Casting, while efficient for producing multiple identical pieces, limits customization due to its reliance on pre-made molds and less flexibility for intricate modifications. Choosing benchwork ensures personalized designs tailored to individual preferences, enhancing the distinctiveness of each jewelry piece.

Sustainability and Waste Management in Both Techniques

Benchwork in jewelry making generates less waste as craftsmen use precise methods to shape metals, allowing for easy recycling of scraps and minimizing environmental impact. Casting involves melting metals, which can produce more material waste and emissions, but adopting lost-wax recycling and using eco-friendly alloys improves sustainability. Efficient waste management practices in both benchwork and casting, including metal recovery systems and reducing chemical use, are crucial for eco-conscious jewelry production.

Benchwork vs Casting Infographic

bizdif.com

bizdif.com