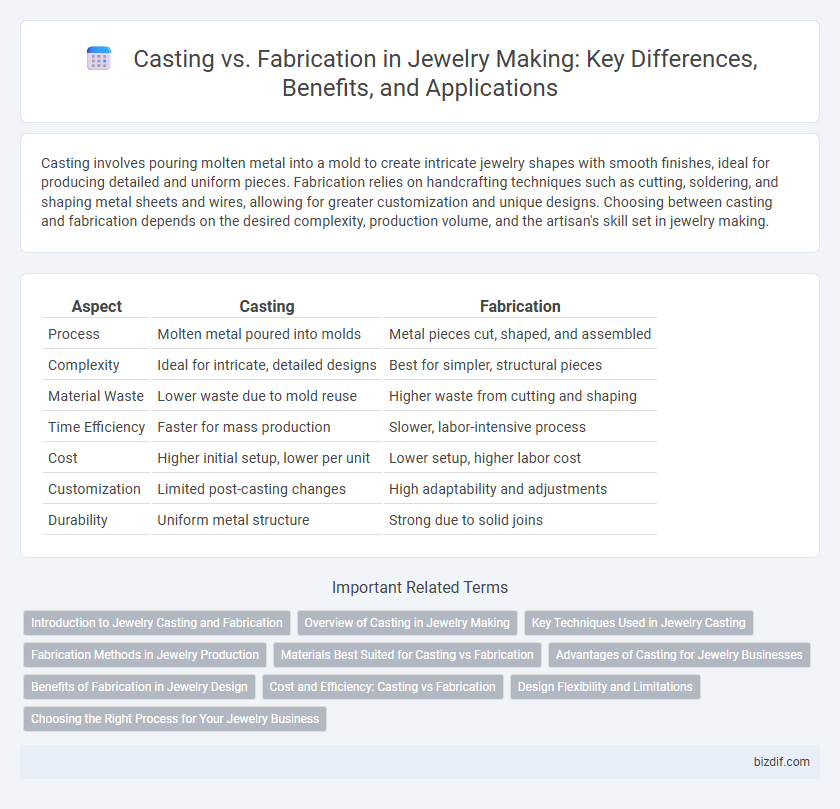

Casting involves pouring molten metal into a mold to create intricate jewelry shapes with smooth finishes, ideal for producing detailed and uniform pieces. Fabrication relies on handcrafting techniques such as cutting, soldering, and shaping metal sheets and wires, allowing for greater customization and unique designs. Choosing between casting and fabrication depends on the desired complexity, production volume, and the artisan's skill set in jewelry making.

Table of Comparison

| Aspect | Casting | Fabrication |

|---|---|---|

| Process | Molten metal poured into molds | Metal pieces cut, shaped, and assembled |

| Complexity | Ideal for intricate, detailed designs | Best for simpler, structural pieces |

| Material Waste | Lower waste due to mold reuse | Higher waste from cutting and shaping |

| Time Efficiency | Faster for mass production | Slower, labor-intensive process |

| Cost | Higher initial setup, lower per unit | Lower setup, higher labor cost |

| Customization | Limited post-casting changes | High adaptability and adjustments |

| Durability | Uniform metal structure | Strong due to solid joins |

Introduction to Jewelry Casting and Fabrication

Jewelry casting involves creating intricate designs by pouring molten metal into molds, allowing for detailed and reproducible pieces. Fabrication relies on hand tools and techniques such as sawing, soldering, and hammering to shape metal components individually. Both methods are essential in jewelry making, offering distinct advantages in design flexibility and production efficiency.

Overview of Casting in Jewelry Making

Casting in jewelry making involves pouring molten metal into a mold to create intricate and precise designs, allowing for high detail and consistency in production. This method is ideal for replicating complex shapes and is commonly used for producing rings, pendants, and other ornamental pieces. Compared to fabrication, casting offers faster mass production while maintaining quality and durability of the jewelry components.

Key Techniques Used in Jewelry Casting

Jewelry casting involves key techniques such as lost-wax casting, where a wax model is encased in a refractory mold and melted away to form a cavity for molten metal. Investment casting ensures high detail and precision by using a silica-based investment material to create the mold. Centrifugal and vacuum casting methods improve metal flow and reduce defects, enhancing the quality of intricate designs in fine jewelry production.

Fabrication Methods in Jewelry Production

Fabrication methods in jewelry production involve shaping and assembling metals through techniques such as soldering, hammering, bending, and cutting to create intricate designs without melting the material. This hands-on approach allows jewelers to achieve precise detailing and structural integrity, often used for custom or one-of-a-kind pieces. Unlike casting, fabrication provides greater control over metal thickness and texture, enhancing durability and artistic expression in finished jewelry.

Materials Best Suited for Casting vs Fabrication

Precious metals like gold, silver, and platinum are best suited for casting due to their excellent meltability and ability to capture intricate details in molds. Fabrication excels with metals such as brass, copper, and stainless steel, offering superior strength and durability through techniques like soldering and bending. Choosing the right material depends on the desired design complexity and structural requirements of the jewelry piece.

Advantages of Casting for Jewelry Businesses

Casting offers jewelry businesses precise replication of intricate designs, enhancing production efficiency and consistency. This technique reduces material waste by accurately melting and pouring metals into molds, lowering overall costs. Casting also enables scalability, allowing manufacturers to produce large quantities of complex pieces quickly without sacrificing detail or quality.

Benefits of Fabrication in Jewelry Design

Fabrication in jewelry design offers unparalleled precision and flexibility, allowing artisans to create intricate custom pieces with unique shapes and textures that casting often cannot achieve. This method reduces material waste and enhances durability by enabling direct manipulation of metals through techniques such as soldering, bending, and cutting. Fabrication also supports on-demand adjustments and repairs, making it an ideal choice for personalized, high-quality jewelry creation.

Cost and Efficiency: Casting vs Fabrication

Casting in jewelry making often involves higher initial costs due to mold creation but allows for efficient mass production with consistent quality and reduced labor expenses. Fabrication requires more skilled manual labor and time, leading to higher per-piece costs especially for complex designs, but offers greater flexibility for customization and one-of-a-kind pieces. Choosing casting optimizes cost efficiency for large runs, while fabrication suits bespoke projects where unique craftsmanship justifies the expense.

Design Flexibility and Limitations

Casting offers high design flexibility by enabling intricate, complex shapes and fine details to be reproduced consistently from molds, ideal for detailed jewelry pieces. Fabrication allows for greater customization and alterations during the creation process but is limited by the artisan's manual skills and tools, restricting extremely delicate or repetitive designs. Each method's design limitations directly impact the choice between mass production with precision and bespoke craftsmanship with adaptability.

Choosing the Right Process for Your Jewelry Business

Casting offers intricate detail and mass production efficiency, ideal for businesses focusing on complex and repeatable designs. Fabrication provides greater flexibility and craftsmanship, suited for custom or one-of-a-kind pieces requiring manual manipulation of metals. Evaluating project scale, design complexity, and production volume helps determine the optimal process to maximize quality and profitability in jewelry making.

Casting vs Fabrication Infographic

bizdif.com

bizdif.com