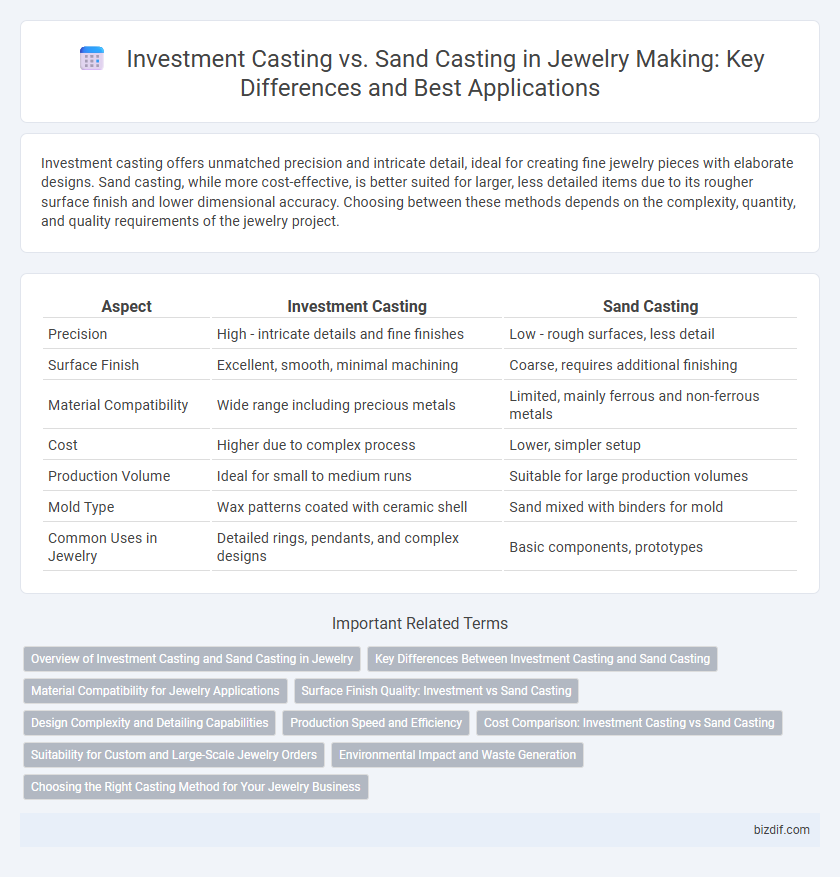

Investment casting offers unmatched precision and intricate detail, ideal for creating fine jewelry pieces with elaborate designs. Sand casting, while more cost-effective, is better suited for larger, less detailed items due to its rougher surface finish and lower dimensional accuracy. Choosing between these methods depends on the complexity, quantity, and quality requirements of the jewelry project.

Table of Comparison

| Aspect | Investment Casting | Sand Casting |

|---|---|---|

| Precision | High - intricate details and fine finishes | Low - rough surfaces, less detail |

| Surface Finish | Excellent, smooth, minimal machining | Coarse, requires additional finishing |

| Material Compatibility | Wide range including precious metals | Limited, mainly ferrous and non-ferrous metals |

| Cost | Higher due to complex process | Lower, simpler setup |

| Production Volume | Ideal for small to medium runs | Suitable for large production volumes |

| Mold Type | Wax patterns coated with ceramic shell | Sand mixed with binders for mold |

| Common Uses in Jewelry | Detailed rings, pendants, and complex designs | Basic components, prototypes |

Overview of Investment Casting and Sand Casting in Jewelry

Investment casting in jewelry involves creating intricate, precise pieces by pouring molten metal into ceramic molds crafted from wax models, enabling high detail and smooth finishes. Sand casting uses sand molds to form metal shapes, which is more cost-effective but less precise, often resulting in rougher textures suitable for larger or simpler jewelry designs. Both methods vary significantly in mold material, detail accuracy, and surface quality, impacting the final jewelry aesthetics and production costs.

Key Differences Between Investment Casting and Sand Casting

Investment casting offers superior precision and intricate detail, ideal for delicate jewelry components, while sand casting is more cost-effective but yields rougher surfaces and less accuracy. Investment casting uses wax patterns and ceramic molds, resulting in fine finishes with minimal machining, whereas sand casting employs sand molds, suitable for larger, less detailed pieces. The choice between investment and sand casting depends on desired detail, production volume, and budget constraints in jewelry making.

Material Compatibility for Jewelry Applications

Investment casting offers superior material compatibility for jewelry making, accommodating precious metals like gold, silver, and platinum with high precision and smooth surface finishes. Sand casting, while more cost-effective, often struggles with fine detail and may introduce impurities or rough textures unsuitable for delicate jewelry pieces. Choosing investment casting ensures better fidelity to intricate designs and consistent material quality essential for high-end jewelry applications.

Surface Finish Quality: Investment vs Sand Casting

Investment casting in jewelry making provides a superior surface finish quality with smooth, intricate details and minimal surface imperfections, ideal for delicate designs. Sand casting often results in a rougher texture due to the granular nature of the sand mold, requiring extensive finishing work to achieve a polished appearance. The precision of investment casting reduces post-processing time, enhancing the final product's aesthetic and value.

Design Complexity and Detailing Capabilities

Investment casting offers superior design complexity and fine detailing capabilities compared to sand casting, making it ideal for intricate jewelry pieces with delicate features. The wax patterns used in investment casting allow for precise reproduction of complex shapes and surface textures, resulting in high-quality finishes with minimal post-processing. Sand casting, while cost-effective for bulkier designs, lacks the resolution needed for detailed jewelry, often requiring additional machining to achieve finer details.

Production Speed and Efficiency

Investment casting offers higher production speed and superior precision compared to sand casting, making it ideal for creating intricate jewelry designs with minimal finishing required. Sand casting, while slower due to its manual mold preparation, allows for larger production runs at lower costs but often demands additional polishing and finishing. Efficiency in jewelry making is enhanced with investment casting through reduced material waste and quicker turnaround times, streamlining the manufacturing process.

Cost Comparison: Investment Casting vs Sand Casting

Investment casting involves higher initial costs due to precise wax pattern creation and metal mold fabrication, but it offers superior detail and minimal finishing, reducing long-term labor expenses. Sand casting has lower upfront costs with reusable sand molds but often requires more machining and surface finishing, increasing overall production time and labor. For high-volume jewelry production, investment casting's efficiency and superior quality justify its greater initial investment compared to the more cost-effective but less precise sand casting method.

Suitability for Custom and Large-Scale Jewelry Orders

Investment casting offers high precision and fine detail, making it ideal for custom jewelry orders requiring intricate designs and smooth finishes. Sand casting, being more cost-effective and faster, suits large-scale production but may lack the fine detail needed for delicate jewelry pieces. Jewelry makers often choose investment casting for bespoke creations and sand casting for bulk manufacturing due to these specific advantages.

Environmental Impact and Waste Generation

Investment casting in jewelry making produces less waste due to precise mold creation from wax patterns, minimizing material loss and reducing the need for extensive machining. Sand casting generates more environmental impact through high sand consumption and difficult mold recycling, leading to increased solid waste and energy use. Choosing investment casting supports sustainable practices by lowering emissions and promoting resource efficiency in metal usage.

Choosing the Right Casting Method for Your Jewelry Business

Investment casting provides unparalleled precision and detail, ideal for intricate jewelry designs requiring smooth surfaces and fine features. Sand casting offers cost-effective, larger-scale production but may result in rougher finishes and less intricate detail, suitable for bold, textured pieces. Selecting the right casting method depends on design complexity, budget, and production volume, ensuring optimal quality and profitability for your jewelry business.

Investment casting vs Sand casting Infographic

bizdif.com

bizdif.com