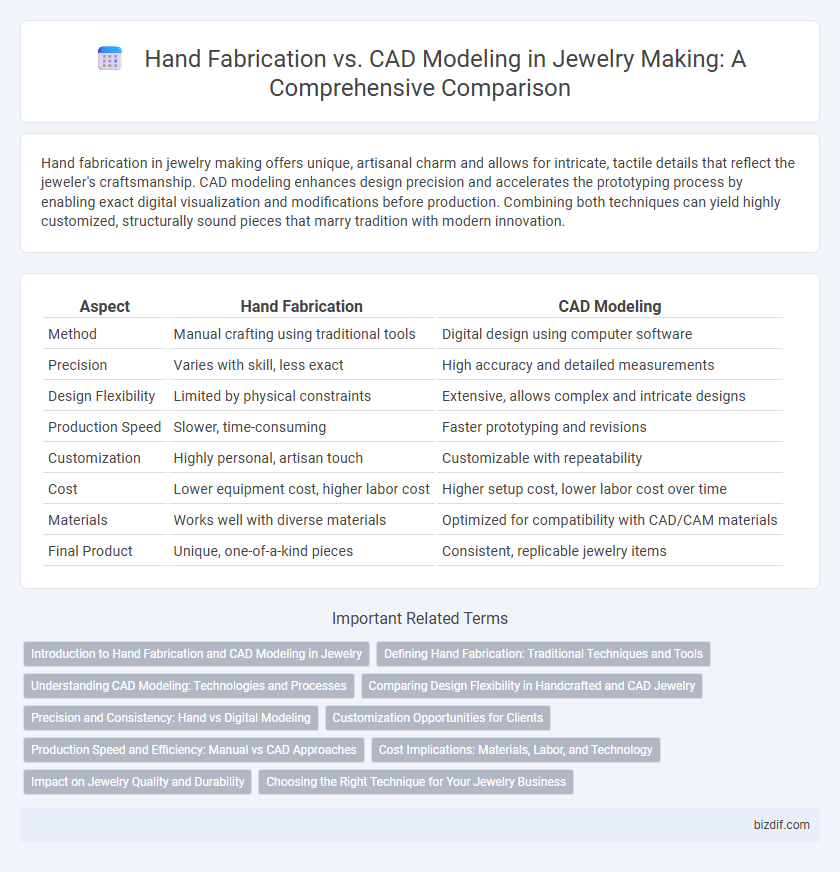

Hand fabrication in jewelry making offers unique, artisanal charm and allows for intricate, tactile details that reflect the jeweler's craftsmanship. CAD modeling enhances design precision and accelerates the prototyping process by enabling exact digital visualization and modifications before production. Combining both techniques can yield highly customized, structurally sound pieces that marry tradition with modern innovation.

Table of Comparison

| Aspect | Hand Fabrication | CAD Modeling |

|---|---|---|

| Method | Manual crafting using traditional tools | Digital design using computer software |

| Precision | Varies with skill, less exact | High accuracy and detailed measurements |

| Design Flexibility | Limited by physical constraints | Extensive, allows complex and intricate designs |

| Production Speed | Slower, time-consuming | Faster prototyping and revisions |

| Customization | Highly personal, artisan touch | Customizable with repeatability |

| Cost | Lower equipment cost, higher labor cost | Higher setup cost, lower labor cost over time |

| Materials | Works well with diverse materials | Optimized for compatibility with CAD/CAM materials |

| Final Product | Unique, one-of-a-kind pieces | Consistent, replicable jewelry items |

Introduction to Hand Fabrication and CAD Modeling in Jewelry

Hand fabrication in jewelry involves crafting pieces manually using traditional tools such as saws, files, and soldering torches, allowing artisans to directly manipulate metals for unique, detailed designs. CAD modeling employs computer-aided design software to create precise, digital 3D models of jewelry, enabling complex geometries and efficient prototyping. Both techniques offer distinct advantages, with hand fabrication emphasizing craftsmanship and tactile control, while CAD modeling focuses on accuracy and repeatability in design.

Defining Hand Fabrication: Traditional Techniques and Tools

Hand fabrication in jewelry making involves traditional techniques such as soldering, shaping, and texturing metals using tools like hammers, files, and torches. This method emphasizes craftsmanship and allows artisans to create one-of-a-kind pieces through manual manipulation of materials. It contrasts with CAD modeling by prioritizing tactile skills and direct interaction with physical metals instead of digital design processes.

Understanding CAD Modeling: Technologies and Processes

CAD modeling in jewelry making utilizes advanced technologies such as 3D scanning, parametric design, and computer-aided drafting to create precise digital prototypes. This process enables jewelers to simulate complex designs, optimize material usage, and streamline production workflows before physical fabrication. Software tools like Rhino, MatrixGold, and ZBrush facilitate detailed customization, enhancing accuracy and creative possibilities beyond traditional hand fabrication methods.

Comparing Design Flexibility in Handcrafted and CAD Jewelry

Hand fabrication in jewelry making offers unmatched tactile control and organic design flexibility, allowing artisans to create unique, one-of-a-kind pieces with intricate details shaped by hand. CAD modeling enhances design flexibility through precise modifications, complex geometry, and the ability to easily iterate designs digitally before production. While handcrafted jewelry excels in artistic spontaneity and texture variation, CAD enables scalability and consistency in replicating intricate designs.

Precision and Consistency: Hand vs Digital Modeling

Hand fabrication in jewelry making offers unique artisanal precision through skilled craftsmanship, allowing for subtle variations that add character to each piece. CAD modeling delivers unmatched consistency and exactness by utilizing digital measurements and automated processes, ensuring every item matches design specifications perfectly. The integration of CAD technology enhances production accuracy, while hand fabrication preserves the individuality and intricate detailing of handcrafted jewelry.

Customization Opportunities for Clients

Hand fabrication in jewelry making offers unparalleled customization opportunities by allowing artisans to create unique, one-of-a-kind pieces tailored to individual client specifications through meticulous manual techniques. CAD modeling provides clients with precise visualization and design flexibility, enabling adjustments in real time to achieve exact size, shape, and style preferences before production. Combining both methods can enhance customization by merging handcrafted artistry with digital precision, resulting in personalized luxury jewelry.

Production Speed and Efficiency: Manual vs CAD Approaches

Hand fabrication in jewelry making often involves meticulous manual techniques that can be time-consuming, leading to slower production speeds and variable efficiency depending on artisan skill. CAD modeling streamlines the design process by enabling precise digital creations that can be rapidly prototyped and reproduced, significantly enhancing production speed and consistency. Integrating CAD technology into jewelry manufacturing optimizes workflow efficiency and reduces errors compared to traditional hand-fabricated methods.

Cost Implications: Materials, Labor, and Technology

Hand fabrication in jewelry making typically incurs higher labor costs due to skilled craftsmanship and time-intensive processes, while CAD modeling reduces labor expenses by streamlining design and production. Material usage in hand fabrication can be less efficient, with more waste from manual cutting and shaping, whereas CAD allows for precise calculations and minimal material loss. Technology investment in CAD requires upfront costs for software and equipment but offers long-term savings through improved accuracy, faster prototyping, and reduced error rates.

Impact on Jewelry Quality and Durability

Hand fabrication in jewelry making ensures exceptional craftsmanship with meticulous attention to detail, resulting in uniquely durable pieces that often exhibit superior strength due to manual shaping and soldering techniques. CAD modeling offers precision and consistency, enabling complex designs that maintain high structural integrity through computer-aided accuracy and repeatability. The combination of traditional hand fabrication and advanced CAD technology significantly enhances overall jewelry quality and durability by leveraging the strengths of both methods.

Choosing the Right Technique for Your Jewelry Business

Hand fabrication offers unmatched craftsmanship and customization through traditional techniques like soldering and shaping, ideal for unique, high-end pieces. CAD modeling enhances precision and efficiency by enabling detailed digital designs and rapid prototyping, perfect for scalable production. Selecting the right technique depends on business goals, budget, and desired product complexity to balance artistry with technological advantage.

Hand fabrication vs CAD modeling Infographic

bizdif.com

bizdif.com