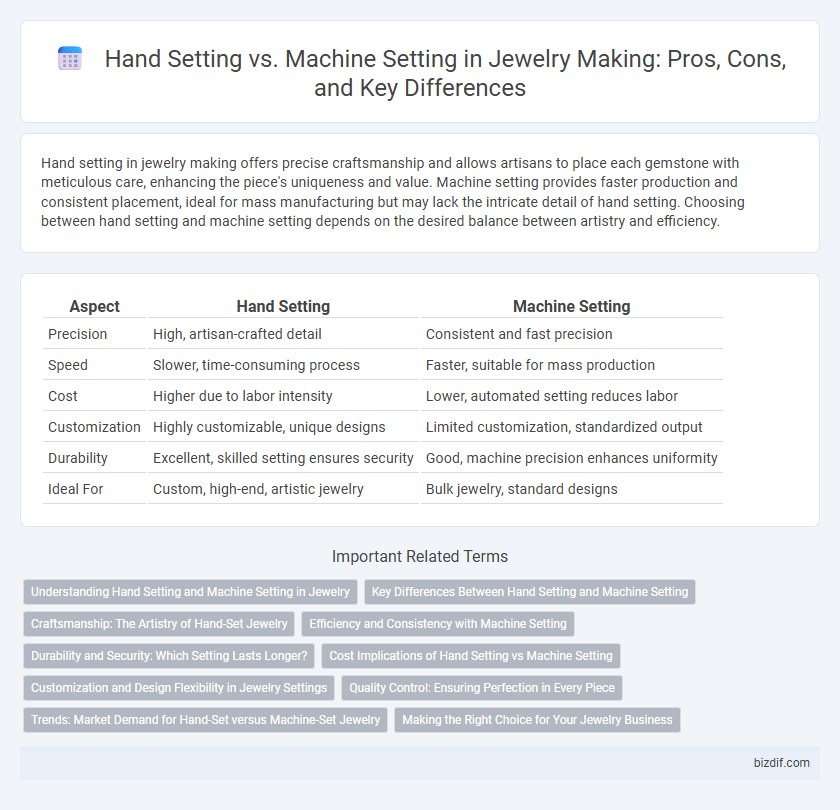

Hand setting in jewelry making offers precise craftsmanship and allows artisans to place each gemstone with meticulous care, enhancing the piece's uniqueness and value. Machine setting provides faster production and consistent placement, ideal for mass manufacturing but may lack the intricate detail of hand setting. Choosing between hand setting and machine setting depends on the desired balance between artistry and efficiency.

Table of Comparison

| Aspect | Hand Setting | Machine Setting |

|---|---|---|

| Precision | High, artisan-crafted detail | Consistent and fast precision |

| Speed | Slower, time-consuming process | Faster, suitable for mass production |

| Cost | Higher due to labor intensity | Lower, automated setting reduces labor |

| Customization | Highly customizable, unique designs | Limited customization, standardized output |

| Durability | Excellent, skilled setting ensures security | Good, machine precision enhances uniformity |

| Ideal For | Custom, high-end, artistic jewelry | Bulk jewelry, standard designs |

Understanding Hand Setting and Machine Setting in Jewelry

Hand setting in jewelry involves a skilled artisan carefully placing each gemstone by hand, ensuring precise alignment and enhancing the piece's overall craftsmanship and uniqueness. Machine setting uses automated technology to embed stones quickly and uniformly, increasing production speed and consistency for mass-produced jewelry. Both techniques impact the final quality, with hand setting offering customization and detail, while machine setting provides efficiency and uniformity.

Key Differences Between Hand Setting and Machine Setting

Hand setting in jewelry making involves skilled artisans meticulously placing each gemstone by hand, offering precise control and customization for unique designs. Machine setting utilizes automated equipment to position stones quickly and consistently, enhancing production speed and uniformity for mass-produced pieces. Key differences include the level of craftsmanship, time efficiency, cost implications, and the ability to handle complex or delicate stone placements.

Craftsmanship: The Artistry of Hand-Set Jewelry

Hand setting in jewelry making highlights meticulous craftsmanship, allowing artisans to individually place each gemstone with precision and care, resulting in unique, intricate designs. Machine setting offers speed and uniformity, but it often lacks the nuanced detail and artistic expression found in hand-set pieces. The artistry of hand-set jewelry preserves traditional techniques and elevates each creation into a wearable work of art, showcasing exceptional skill and dedication.

Efficiency and Consistency with Machine Setting

Machine setting in jewelry making offers superior efficiency and consistency compared to hand setting, drastically reducing production time while maintaining uniform quality. Automated machines precisely place stones with minimal error, enhancing overall accuracy and repeatability in large-scale manufacturing. This technological advantage ensures scalable output and consistent aesthetic appeal across batches, essential for commercial jewelers.

Durability and Security: Which Setting Lasts Longer?

Hand setting offers superior durability and security due to the jeweler's precise craftsmanship, ensuring each stone is securely fastened with minimal risk of loosening over time. Machine setting, while faster and more uniform, may be less reliable in withstanding daily wear and tear because it often involves less intricate metal work around the stones. The longevity of hand-set jewelry typically surpasses machine-set pieces, making it a preferred choice for high-value or sentimental items that require lasting durability.

Cost Implications of Hand Setting vs Machine Setting

Hand setting in jewelry making typically incurs higher labor costs due to the skilled craftsmanship required, resulting in increased overall expense compared to machine setting. Machine setting reduces production time and labor expenses by utilizing automated precision, making it more cost-effective for large-scale manufacturing. Despite the higher initial cost, hand setting often adds value to the piece through intricate detail and unique design, which can justify the investment for premium and custom jewelry.

Customization and Design Flexibility in Jewelry Settings

Hand setting in jewelry making offers unparalleled customization and design flexibility, allowing artisans to meticulously place each stone with precision tailored to unique designs and intricate patterns. Machine setting streamlines production but often limits creative freedom, as settings follow standardized templates that can restrict design complexity. Custom jewelry pieces benefit from hand setting by enabling bespoke arrangements and detailed craftsmanship that machines cannot replicate.

Quality Control: Ensuring Perfection in Every Piece

Hand setting in jewelry making allows expert artisans to meticulously place each stone, ensuring precise alignment and balance that machines may overlook. Machine setting offers consistent, high-speed production but can sometimes sacrifice the nuanced quality control achieved through manual inspection. Combining both methods optimizes quality control, guaranteeing flawless craftsmanship and durability in every piece.

Trends: Market Demand for Hand-Set versus Machine-Set Jewelry

Market demand for hand-set jewelry remains strong among consumers valuing artisanal craftsmanship and unique, intricate designs, driving brands to highlight bespoke features. Machine-set jewelry gains traction through mass production efficiency and consistent quality, appealing to budget-conscious buyers and fast fashion markets. Emerging trends show a hybrid approach, combining hand-setting precision with machine setting speed to meet diverse customer preferences and optimize production costs.

Making the Right Choice for Your Jewelry Business

Hand setting provides unparalleled precision and artistry, allowing jewelers to customize each piece with intricate detail and unique stone placement. Machine setting offers speed and uniformity, ideal for high-volume production and consistent quality across large batches. Evaluating your business goals, production scale, and customer expectations will guide the optimal choice between the craftsmanship of hand setting and the efficiency of machine setting.

Hand setting vs Machine setting Infographic

bizdif.com

bizdif.com