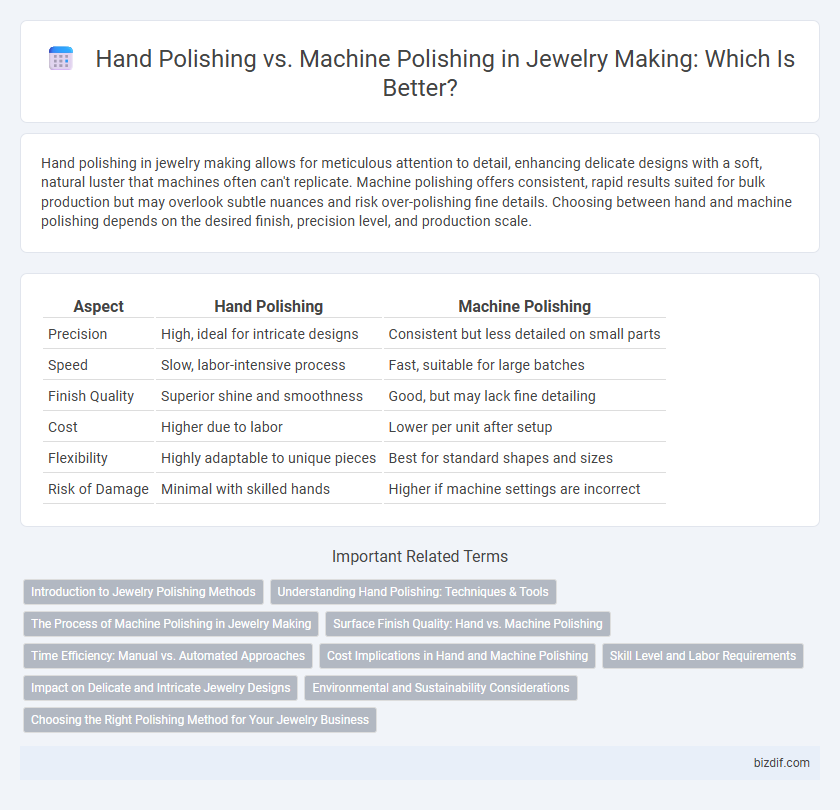

Hand polishing in jewelry making allows for meticulous attention to detail, enhancing delicate designs with a soft, natural luster that machines often can't replicate. Machine polishing offers consistent, rapid results suited for bulk production but may overlook subtle nuances and risk over-polishing fine details. Choosing between hand and machine polishing depends on the desired finish, precision level, and production scale.

Table of Comparison

| Aspect | Hand Polishing | Machine Polishing |

|---|---|---|

| Precision | High, ideal for intricate designs | Consistent but less detailed on small parts |

| Speed | Slow, labor-intensive process | Fast, suitable for large batches |

| Finish Quality | Superior shine and smoothness | Good, but may lack fine detailing |

| Cost | Higher due to labor | Lower per unit after setup |

| Flexibility | Highly adaptable to unique pieces | Best for standard shapes and sizes |

| Risk of Damage | Minimal with skilled hands | Higher if machine settings are incorrect |

Introduction to Jewelry Polishing Methods

Jewelry polishing methods include hand polishing and machine polishing, each offering unique advantages for achieving a high-quality finish. Hand polishing provides precise control and is ideal for delicate or intricate designs where attention to detail is essential. Machine polishing enhances efficiency and consistency, making it suitable for larger batches and simpler shapes, thereby streamlining the jewelry production process.

Understanding Hand Polishing: Techniques & Tools

Hand polishing in jewelry making involves using fine abrasives, polishing cloths, and rotary tools to achieve a smooth, high-gloss finish on metal surfaces. Techniques such as burnishing and buffing rely on precise manual control to enhance details and preserve intricate designs without removing significant material. Skilled artisans select specific polishing compounds and tools based on the metal type and desired finish, making hand polishing ideal for delicate or custom pieces.

The Process of Machine Polishing in Jewelry Making

Machine polishing in jewelry making involves using automated rotary or vibrating polishing wheels with abrasive compounds to achieve a high-gloss finish on metals and gemstones. This process ensures uniform surface smoothness and significantly reduces production time compared to hand polishing. Precision-controlled machinery can reach intricate areas, enhancing consistency and improving overall jewelry quality.

Surface Finish Quality: Hand vs. Machine Polishing

Hand polishing in jewelry making delivers a unique, refined surface finish that highlights intricate details and allows artisans to control texture with precision, often resulting in a more customized appearance. Machine polishing offers consistent, uniform surface finishes suitable for high-volume production, efficiently smoothing out imperfections at a faster rate. The choice between hand and machine polishing impacts the final aesthetic and tactile quality, with hand polishing favored for bespoke pieces and machine polishing preferred for standardized finishes.

Time Efficiency: Manual vs. Automated Approaches

Hand polishing in jewelry making demands significant time and skilled labor, often requiring several hours to achieve a smooth, reflective surface on intricate pieces. Machine polishing, leveraging automated rotary or vibratory systems, drastically reduces processing time while ensuring consistent finish quality across batches. Time efficiency in automated polishing enhances production scalability, making it preferable for mass manufacturing without compromising detail.

Cost Implications in Hand and Machine Polishing

Hand polishing in jewelry making often involves higher labor costs due to the time-intensive, skilled craftsmanship required to achieve fine details and unique finishes. Machine polishing reduces labor expenses by offering faster processing times and consistent results, though it may involve significant initial investment in equipment and maintenance. Balancing cost implications requires considering production volume, desired finish quality, and long-term operational expenses for either hand or machine polishing.

Skill Level and Labor Requirements

Hand polishing in jewelry making demands a high skill level, as artisans use specialized tools and techniques to achieve intricate finishes on delicate pieces, resulting in unique craftsmanship. Machine polishing requires less manual dexterity, relying on automated equipment that increases efficiency but may lack the refined detail attainable by hand. Labor requirements for hand polishing are intensive, involving careful attention and time, whereas machine polishing allows for faster processing with reduced physical effort.

Impact on Delicate and Intricate Jewelry Designs

Hand polishing preserves the fine details and delicate features of intricate jewelry designs by allowing skilled artisans to carefully maneuver around tiny components without causing damage. Machine polishing, while faster, risks eroding intricate patterns and delicate settings due to its aggressive abrasion and less precise control. For jewelry with complex designs and fragile elements, hand polishing ensures a superior finish with minimal risk of compromising the piece's structural integrity.

Environmental and Sustainability Considerations

Hand polishing in jewelry making minimizes energy consumption and reduces carbon emissions compared to machine polishing, making it a more environmentally friendly choice. Manual techniques also limit the use of harsh chemicals and generate less metal waste, supporting sustainable production practices. While machine polishing offers speed, its higher electricity usage and potential for increased material loss pose greater sustainability challenges in eco-conscious jewelry crafting.

Choosing the Right Polishing Method for Your Jewelry Business

Hand polishing offers exceptional control and precision, ideal for intricate or delicate jewelry designs requiring a gentle touch. Machine polishing delivers consistent, high-speed results for high-volume production, maximizing efficiency without compromising surface shine. Evaluating factors like jewelry complexity, production scale, and desired finish quality helps determine the most suitable polishing method for your jewelry business.

Hand Polishing vs Machine Polishing Infographic

bizdif.com

bizdif.com