Jewelers' torches provide precise control and versatility for soldering various metals, making them ideal for traditional jewelry crafting and repairs. Laser soldering offers exceptional accuracy and minimal heat impact, reducing the risk of damage to delicate pieces and allowing for more intricate designs. Choosing between the two methods depends on the complexity of the work, material sensitivity, and desired finish quality.

Table of Comparison

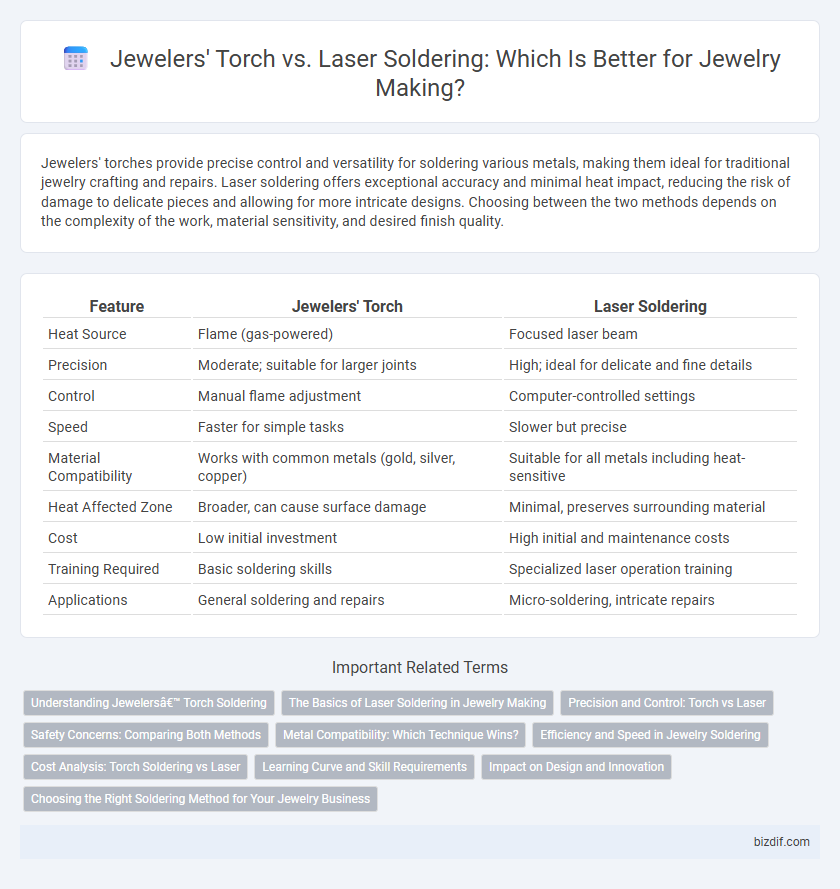

| Feature | Jewelers' Torch | Laser Soldering |

|---|---|---|

| Heat Source | Flame (gas-powered) | Focused laser beam |

| Precision | Moderate; suitable for larger joints | High; ideal for delicate and fine details |

| Control | Manual flame adjustment | Computer-controlled settings |

| Speed | Faster for simple tasks | Slower but precise |

| Material Compatibility | Works with common metals (gold, silver, copper) | Suitable for all metals including heat-sensitive |

| Heat Affected Zone | Broader, can cause surface damage | Minimal, preserves surrounding material |

| Cost | Low initial investment | High initial and maintenance costs |

| Training Required | Basic soldering skills | Specialized laser operation training |

| Applications | General soldering and repairs | Micro-soldering, intricate repairs |

Understanding Jewelers’ Torch Soldering

Jewelers' torch soldering offers precise control of heat using a flame fueled by gases like propane or acetylene, ideal for intricate metalwork and delicate repairs in jewelry making. This technique enables artisans to apply localized heat, ensuring strong, seamless joins on metals such as gold, silver, and platinum while maintaining the integrity of gemstones. Understanding the flame's intensity and flame shape is crucial for achieving optimal solder flow and preventing material damage during the soldering process.

The Basics of Laser Soldering in Jewelry Making

Laser soldering in jewelry making utilizes focused light energy to precisely melt solder, enabling clean, controlled joins without direct flame contact. This method offers enhanced accuracy for delicate pieces, reducing heat distortion commonly associated with jewelers' torches. Laser soldering allows intricate repairs and fine detailing, making it ideal for modern, high-precision jewelry fabrication.

Precision and Control: Torch vs Laser

Torch soldering offers artisans tactile control and flexibility, allowing for precise manipulation of heat and movement on intricate jewelry pieces. Laser soldering delivers unparalleled accuracy by concentrating a fine, focused beam of energy, reducing heat spread and minimizing risk to delicate components. Jewelers prioritize laser technology for ultra-fine, micro-soldering tasks demanding exact precision, whereas torches remain preferred for broader, hands-on applications requiring adaptive heat control.

Safety Concerns: Comparing Both Methods

Jewelers' torches pose higher risks of burns, inhalation of harmful fumes, and fire hazards due to open flames and intense heat. Laser soldering minimizes physical contact, reduces exposure to hazardous fumes, and offers precise heat application, significantly enhancing workplace safety. Proper ventilation, protective eyewear, and trained handling are essential safety measures for both methods in jewelry making.

Metal Compatibility: Which Technique Wins?

Jewelers' torch offers superior versatility by accommodating a wide range of metals, including gold, silver, copper, and brass, due to its adjustable flame temperature and direct heat application. Laser soldering, while precise and effective for delicate or small-scale repairs, is typically limited to metals that respond well to controlled laser energy, such as gold and platinum, but may struggle with materials like copper or brass. The torch remains the preferred choice for broad metal compatibility in jewelry making, ensuring reliable solder joints across diverse alloys.

Efficiency and Speed in Jewelry Soldering

Jewelers' torches provide precise control over heat application, making them efficient for small-scale and detailed soldering tasks that require quick adjustments and immediate flame response. Laser soldering offers superior speed by enabling rapid, localized heat delivery with minimal thermal distortion, ideal for delicate or complex designs requiring high precision in less time. Efficiency in jewelry soldering depends on project complexity, with torches excelling in flexible, hands-on work and laser soldering advantageous for fast, consistent results on intricate pieces.

Cost Analysis: Torch Soldering vs Laser

Torch soldering requires lower initial investment with torches costing between $50 and $500, while laser soldering systems range from $20,000 to over $100,000. Operating expenses for torch soldering include fuel and regularly replacing tips, which remain relatively affordable compared to the maintenance and calibration costs necessary for laser equipment. Efficiency gains with laser soldering can reduce labor costs and improve precision, but the significant upfront and upkeep expenses make torch soldering a more economical choice for small-scale jewelers.

Learning Curve and Skill Requirements

Jewelers' torch soldering demands extensive hands-on practice to master the precise flame control and heat application essential for delicate metalwork, making it a steep learning curve for beginners. Laser soldering offers more precision with reduced thermal impact, yet requires specialized training to operate high-tech equipment effectively. Both techniques demand a strong understanding of metal properties, but laser soldering shifts focus toward handling advanced technology, while torch soldering emphasizes traditional craftsmanship skills.

Impact on Design and Innovation

Jewelers' torch offers hands-on control, allowing artisans to create intricate, unique designs with tailored heat application that fosters traditional craftsmanship and artistic expression. Laser soldering enables precise, minimally invasive connections, facilitating innovative designs with complex structures and delicate materials that are challenging for torch methods. Integration of laser technology accelerates design experimentation and refines detailing, pushing boundaries in jewelry innovation and production efficiency.

Choosing the Right Soldering Method for Your Jewelry Business

Choosing the right soldering method for your jewelry business depends on the precision, speed, and volume of your production needs. Jewelers' torches offer versatility and control for detailed, small-batch work, while laser soldering provides high accuracy and efficiency for complex designs and larger-scale manufacturing. Evaluating factors like project complexity, budget, and desired finish quality helps determine whether traditional torch soldering or advanced laser technology best suits your workshop.

Jewelers’ Torch vs Laser Soldering Infographic

bizdif.com

bizdif.com