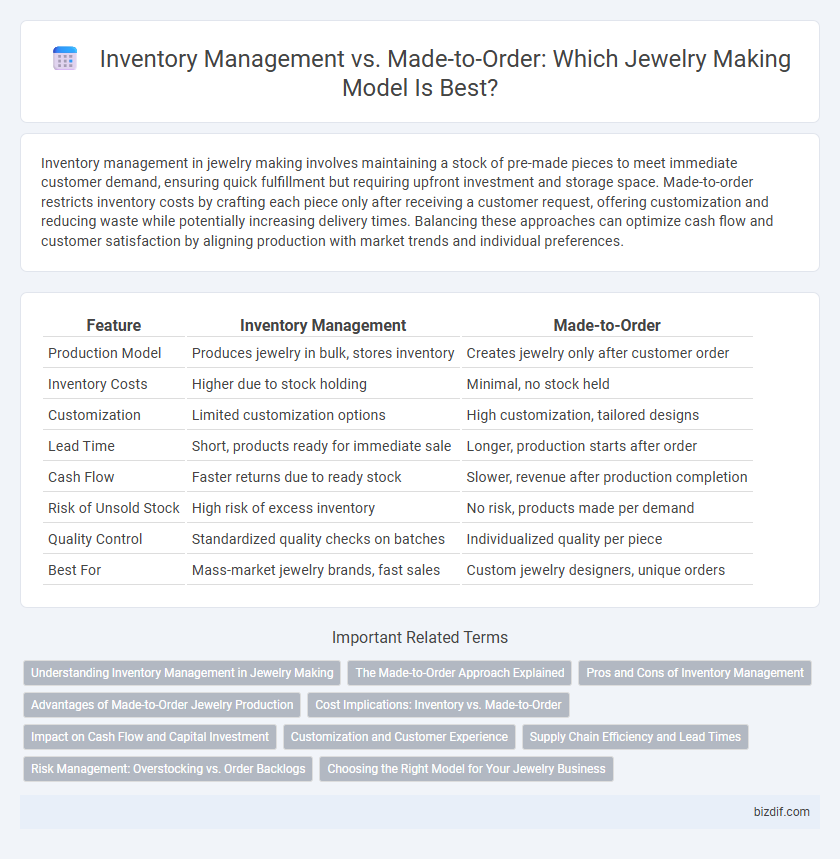

Inventory management in jewelry making involves maintaining a stock of pre-made pieces to meet immediate customer demand, ensuring quick fulfillment but requiring upfront investment and storage space. Made-to-order restricts inventory costs by crafting each piece only after receiving a customer request, offering customization and reducing waste while potentially increasing delivery times. Balancing these approaches can optimize cash flow and customer satisfaction by aligning production with market trends and individual preferences.

Table of Comparison

| Feature | Inventory Management | Made-to-Order |

|---|---|---|

| Production Model | Produces jewelry in bulk, stores inventory | Creates jewelry only after customer order |

| Inventory Costs | Higher due to stock holding | Minimal, no stock held |

| Customization | Limited customization options | High customization, tailored designs |

| Lead Time | Short, products ready for immediate sale | Longer, production starts after order |

| Cash Flow | Faster returns due to ready stock | Slower, revenue after production completion |

| Risk of Unsold Stock | High risk of excess inventory | No risk, products made per demand |

| Quality Control | Standardized quality checks on batches | Individualized quality per piece |

| Best For | Mass-market jewelry brands, fast sales | Custom jewelry designers, unique orders |

Understanding Inventory Management in Jewelry Making

Inventory management in jewelry making involves maintaining an optimal stock of raw materials and finished pieces to meet customer demand efficiently. It requires tracking gemstones, metals, and components to minimize holding costs while ensuring timely production and delivery. Effective inventory control reduces waste, prevents overstocking, and improves cash flow for jewelers balancing supply and demand.

The Made-to-Order Approach Explained

The made-to-order approach in jewelry making involves crafting pieces only after receiving a customer's specific request, which reduces the need for extensive inventory storage and minimizes material waste. This method ensures personalized, unique designs tailored to individual preferences, enhancing customer satisfaction and exclusivity. By contrast, traditional inventory management requires maintaining stock of finished items, potentially leading to overproduction and increased holding costs.

Pros and Cons of Inventory Management

Inventory management in jewelry making allows for immediate product availability, enhancing customer satisfaction and increasing sales potential by meeting demand instantly. However, it requires significant upfront investment and carries the risk of unsold stock, leading to potential financial loss and storage costs. Efficient inventory tracking systems and demand forecasting are essential to minimize overproduction and maintain optimal stock levels.

Advantages of Made-to-Order Jewelry Production

Made-to-order jewelry production minimizes inventory costs by eliminating the need for large stockpiles, allowing jewelers to invest in higher-quality materials and craftsmanship. This approach enhances customization options, enabling designers to meet specific customer preferences and trends, which increases customer satisfaction and loyalty. It also reduces waste and storage challenges, improving overall sustainability in the jewelry-making business.

Cost Implications: Inventory vs. Made-to-Order

Inventory management in jewelry making involves upfront investment in raw materials and finished pieces, leading to holding costs such as storage, insurance, and potential depreciation from unsold stock. Made-to-order models reduce overhead by producing items only after receiving customer orders, minimizing waste and tied-up capital but often increasing lead times and per-unit production costs. Balancing these approaches requires analyzing cash flow constraints, market demand predictability, and scalability to optimize profitability and operational efficiency.

Impact on Cash Flow and Capital Investment

Inventory management in jewelry making requires substantial capital investment to maintain stock, which can tie up cash flow and increase storage costs. Made-to-order models minimize upfront expenses by producing pieces only after customer orders, improving cash flow but potentially extending delivery times. Balancing inventory costs with production lead times is crucial for optimizing financial health and meeting market demand.

Customization and Customer Experience

Inventory management in jewelry making streamlines production by keeping ready-made pieces available, reducing wait times but limiting customization options. Made-to-order approaches prioritize unique designs tailored to individual customer preferences, enhancing personalization and satisfaction despite longer delivery periods. Balancing inventory and bespoke orders optimizes customer experience by combining efficiency with exclusive customization.

Supply Chain Efficiency and Lead Times

Inventory management in jewelry making involves maintaining stock levels to meet demand quickly, enhancing supply chain efficiency by reducing lead times and ensuring faster order fulfillment. Made-to-order production minimizes inventory costs and waste but lengthens lead times due to the need for custom crafting after order placement. Balancing these strategies optimizes supply chain responsiveness and customer satisfaction by aligning production speed with demand variability.

Risk Management: Overstocking vs. Order Backlogs

Inventory management in jewelry making mitigates risks of overstocking that tie up capital and lead to outdated designs in fast-changing fashion trends. Made-to-order models minimize inventory costs by producing pieces only after receiving customer orders, reducing the risk of excess stock but risking order backlogs during high demand periods. Efficient risk management requires balancing production schedules with market demand to avoid financial losses from unsold inventory or delayed deliveries that impact customer satisfaction.

Choosing the Right Model for Your Jewelry Business

Inventory management in jewelry businesses enables quick fulfillment by maintaining stock of popular pieces, reducing lead times and ensuring consistent cash flow, while made-to-order models minimize upfront costs and allow for greater customization tailored to customer preferences. Selecting the right model depends on factors such as production capacity, target market demand, and cash flow considerations, with hybrid approaches often balancing inventory availability and bespoke craftsmanship. Effective use of point-of-sale systems and inventory tracking software can optimize stock levels and order processing, enhancing overall operational efficiency in either model.

Inventory management vs Made-to-order Infographic

bizdif.com

bizdif.com