Lost-wax casting offers exceptional precision and intricate detail, making it ideal for creating delicate and complex jewelry designs. Sand casting, while more cost-effective and suitable for larger pieces, often results in a rougher surface finish requiring additional refinement. Choosing between these methods depends on the desired level of detail, production volume, and budget constraints in jewelry making.

Table of Comparison

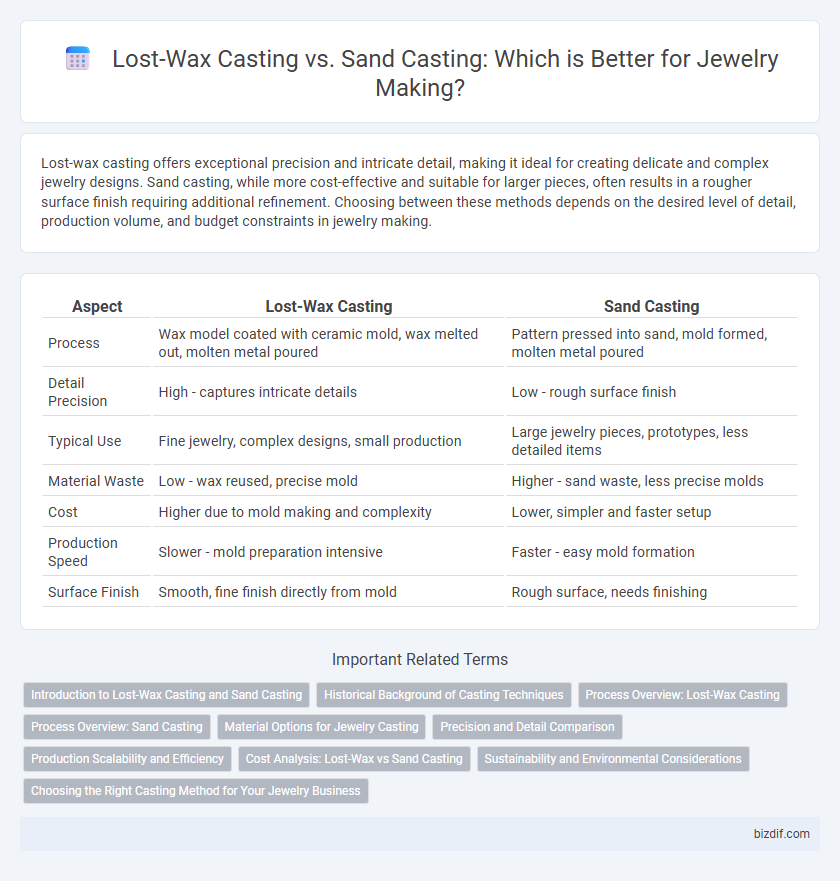

| Aspect | Lost-Wax Casting | Sand Casting |

|---|---|---|

| Process | Wax model coated with ceramic mold, wax melted out, molten metal poured | Pattern pressed into sand, mold formed, molten metal poured |

| Detail Precision | High - captures intricate details | Low - rough surface finish |

| Typical Use | Fine jewelry, complex designs, small production | Large jewelry pieces, prototypes, less detailed items |

| Material Waste | Low - wax reused, precise mold | Higher - sand waste, less precise molds |

| Cost | Higher due to mold making and complexity | Lower, simpler and faster setup |

| Production Speed | Slower - mold preparation intensive | Faster - easy mold formation |

| Surface Finish | Smooth, fine finish directly from mold | Rough surface, needs finishing |

Introduction to Lost-Wax Casting and Sand Casting

Lost-wax casting involves creating a detailed wax model that is encased in a ceramic shell, which is then heated to melt away the wax, leaving a precise mold for molten metal to be poured into, ideal for intricate jewelry designs. Sand casting uses a sand-based mold formed around a pattern, suitable for simpler shapes but less precise detail compared to lost-wax casting. Both methods are foundational in jewelry making, with lost-wax casting preferred for its fine resolution and sand casting valued for cost-effectiveness and rapid prototyping.

Historical Background of Casting Techniques

Lost-wax casting, dating back over 5,000 years to ancient Mesopotamia, has been a pivotal technique in fine jewelry making due to its precision in capturing intricate details from wax models. Sand casting, with origins traced to ancient China and Egypt, involves creating molds from sand and has traditionally been used for producing larger, less detailed metal objects. Understanding these historical casting methods highlights their evolution and enduring significance in the craftsmanship of contemporary jewelry design.

Process Overview: Lost-Wax Casting

Lost-wax casting in jewelry making begins with creating a detailed wax model of the desired piece, which is then encased in a heat-resistant ceramic mold. Once the mold hardens, the wax is melted and drained away, leaving a precise cavity for molten metal to be poured in. This process allows for high-detail replicas, making it ideal for intricate designs and fine jewelry production.

Process Overview: Sand Casting

Sand casting in jewelry making involves creating a mold by packing sand around a wax or metal pattern, which is then removed to leave a cavity. Molten metal is poured into this cavity to form the jewelry piece as it solidifies. This process allows intricate designs and is cost-effective for both prototyping and small production runs, though it typically results in a rougher surface finish compared to lost-wax casting.

Material Options for Jewelry Casting

Lost-wax casting offers a wider range of material options including gold, silver, platinum, and intricate alloys ideal for detailed jewelry designs, while sand casting primarily suits metals like bronze and brass with limited precision. The lost-wax process enables the use of high-melting-point materials and allows for intricate textures, making it favored for fine jewelry pieces. Sand casting is more cost-effective for bulkier, simpler items but less versatile in handling precious or complex materials required for delicate jewelry craftsmanship.

Precision and Detail Comparison

Lost-wax casting offers superior precision and intricate detail reproduction, capturing fine textures and complex designs essential for high-quality jewelry pieces. Sand casting, while more cost-effective, tends to produce rougher surfaces and less detailed results due to the granular nature of the sand mold. Jewelers prioritize lost-wax casting when exactness and elaborate detail are critical, especially for delicate or custom-designed items.

Production Scalability and Efficiency

Lost-wax casting offers superior production scalability and efficiency for jewelry making due to its ability to produce highly detailed and complex designs with minimal post-casting work. This method allows for consistent replication of intricate pieces, making it ideal for both small-batch artisan production and larger runs. Sand casting, while more cost-effective for larger, less detailed items, generally involves longer setup times and less precision, limiting its efficiency for high-volume, detailed jewelry manufacturing.

Cost Analysis: Lost-Wax vs Sand Casting

Lost-wax casting generally incurs higher initial costs due to its detailed wax model creation and specialized investment materials, but it offers superior precision and finer detail for intricate jewelry designs. Sand casting presents a more budget-friendly option with lower setup expenses and reusable sand molds, making it suitable for larger, less detailed pieces or lower production volumes. An effective cost analysis weighs the complexity and quality demands of the jewelry against mold reuse frequency and material expenses to determine the optimal casting method.

Sustainability and Environmental Considerations

Lost-wax casting generates less waste compared to sand casting, as the wax can be reused and the process avoids large volumes of sand disposal. Sand casting often requires significant sand treatment and disposal, which can impact local ecosystems. Choosing lost-wax casting supports more sustainable practices in jewelry making by minimizing material waste and reducing harmful environmental effects.

Choosing the Right Casting Method for Your Jewelry Business

Lost-wax casting offers unparalleled precision and fine detail, making it ideal for intricate jewelry designs and high-quality production runs. Sand casting, while less precise, provides a cost-effective solution for simpler, larger pieces and short-run projects with less detail requirements. Selecting the right casting method depends on your business's design complexity, production volume, and budget constraints to ensure optimal craftsmanship and profitability.

Lost-wax casting vs sand casting Infographic

bizdif.com

bizdif.com