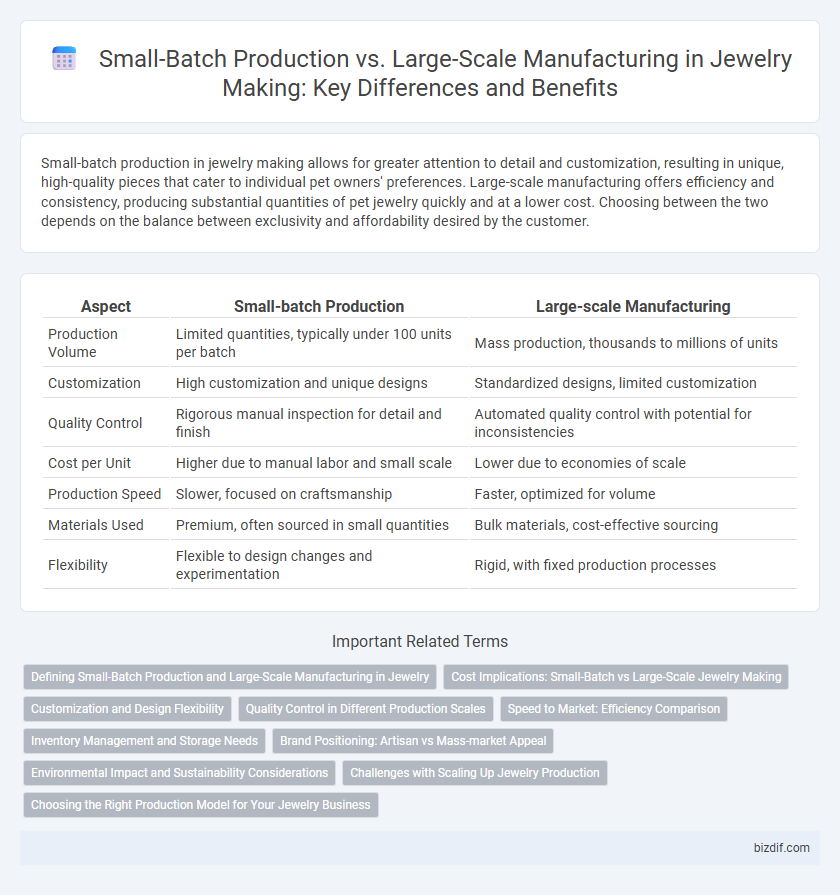

Small-batch production in jewelry making allows for greater attention to detail and customization, resulting in unique, high-quality pieces that cater to individual pet owners' preferences. Large-scale manufacturing offers efficiency and consistency, producing substantial quantities of pet jewelry quickly and at a lower cost. Choosing between the two depends on the balance between exclusivity and affordability desired by the customer.

Table of Comparison

| Aspect | Small-batch Production | Large-scale Manufacturing |

|---|---|---|

| Production Volume | Limited quantities, typically under 100 units per batch | Mass production, thousands to millions of units |

| Customization | High customization and unique designs | Standardized designs, limited customization |

| Quality Control | Rigorous manual inspection for detail and finish | Automated quality control with potential for inconsistencies |

| Cost per Unit | Higher due to manual labor and small scale | Lower due to economies of scale |

| Production Speed | Slower, focused on craftsmanship | Faster, optimized for volume |

| Materials Used | Premium, often sourced in small quantities | Bulk materials, cost-effective sourcing |

| Flexibility | Flexible to design changes and experimentation | Rigid, with fixed production processes |

Defining Small-Batch Production and Large-Scale Manufacturing in Jewelry

Small-batch production in jewelry making involves crafting limited quantities of unique pieces, emphasizing artisanal techniques and customization. Large-scale manufacturing relies on automated processes and mass production to achieve high volume and uniformity across designs. This distinction impacts flexibility, quality control, and the ability to personalize each jewelry item.

Cost Implications: Small-Batch vs Large-Scale Jewelry Making

Small-batch jewelry production often incurs higher per-unit costs due to manual craftsmanship, limited economies of scale, and premium material sourcing, making it ideal for bespoke designs and luxury markets. Large-scale manufacturing benefits from bulk purchasing, automated processes, and streamlined labor, significantly reducing costs and enabling competitive pricing for mass-market jewelry. Balancing quality, customization, and budget constraints is crucial when choosing between small-batch and large-scale jewelry production methods.

Customization and Design Flexibility

Small-batch production in jewelry making offers superior customization and design flexibility, allowing artisans to tailor each piece to specific customer preferences and experiment with unique materials or techniques. Large-scale manufacturing prioritizes efficiency and cost-effectiveness but often limits design variations due to standardized processes and mass production constraints. This trade-off influences the choice between bespoke, intricate designs and uniform, widely available product lines.

Quality Control in Different Production Scales

Small-batch production in jewelry making allows for meticulous quality control through hands-on inspection of each piece, ensuring superior craftsmanship and attention to detail. In contrast, large-scale manufacturing relies heavily on automated processes and statistical sampling methods, which may increase efficiency but can lead to inconsistencies in individual item quality. Balancing production scale with stringent quality control protocols is essential to maintain brand reputation and meet customer expectations in the jewelry industry.

Speed to Market: Efficiency Comparison

Small-batch production enables faster speed to market by allowing jewelers to quickly respond to trends with minimal setup time and flexible workflows. Large-scale manufacturing offers efficiency through economies of scale but often involves longer lead times due to complex machinery and bulk material procurement. Prioritizing small-batch methods enhances agility in launching new designs, while large-scale operations excel in consistent output for established collections.

Inventory Management and Storage Needs

Small-batch production in jewelry making allows for tighter inventory control and reduces storage requirements, as fewer raw materials and finished pieces are stocked at any time. Large-scale manufacturing demands extensive storage facilities and sophisticated inventory management systems to handle bulk materials and finished goods efficiently. Optimizing inventory turnover and minimizing excess stock are critical to preventing storage overflow and reducing carrying costs in both production scales.

Brand Positioning: Artisan vs Mass-market Appeal

Small-batch production in jewelry making emphasizes handcrafted quality and unique designs, aligning with an artisan brand positioned for exclusivity and premium pricing. Large-scale manufacturing targets mass-market appeal, prioritizing consistency, affordability, and widespread distribution to attract a broader customer base. Brand positioning in small-batch production often highlights the story, craftsmanship, and limited availability, whereas large-scale brands focus on accessibility, trends, and volume sales.

Environmental Impact and Sustainability Considerations

Small-batch production in jewelry making significantly reduces environmental impact by minimizing waste, conserving resources, and allowing for the use of ethically sourced materials, promoting sustainability. Large-scale manufacturing often involves energy-intensive processes and mass material consumption, leading to higher carbon footprints and increased waste generation. Prioritizing small-batch practices supports eco-friendly craftsmanship and encourages responsible sourcing, aligning with sustainable industry standards.

Challenges with Scaling Up Jewelry Production

Scaling up jewelry production from small-batch to large-scale manufacturing presents challenges such as maintaining consistent quality and craftsmanship across higher volumes. Suppliers and artisans can struggle with sourcing materials and managing deadlines while preserving intricate design details. Efficient workflow automation and quality control systems become critical to address these scaling complexities without compromising the brand's artistic integrity.

Choosing the Right Production Model for Your Jewelry Business

Small-batch production offers greater customization and quality control, ideal for artisans targeting niche markets or bespoke jewelry clients. Large-scale manufacturing emphasizes efficiency and cost-effectiveness, suited for businesses aiming to meet high demand with consistent designs. Selecting the right production model depends on your brand's goals, target audience, and the balance between exclusivity and scalability.

Small-batch production vs Large-scale manufacturing Infographic

bizdif.com

bizdif.com