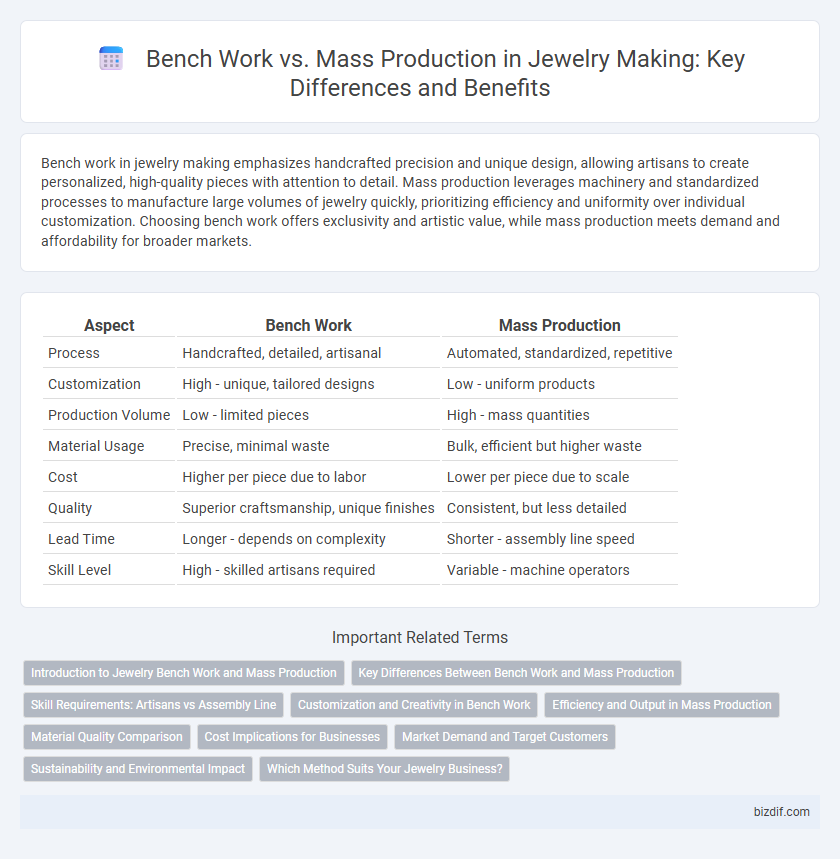

Bench work in jewelry making emphasizes handcrafted precision and unique design, allowing artisans to create personalized, high-quality pieces with attention to detail. Mass production leverages machinery and standardized processes to manufacture large volumes of jewelry quickly, prioritizing efficiency and uniformity over individual customization. Choosing bench work offers exclusivity and artistic value, while mass production meets demand and affordability for broader markets.

Table of Comparison

| Aspect | Bench Work | Mass Production |

|---|---|---|

| Process | Handcrafted, detailed, artisanal | Automated, standardized, repetitive |

| Customization | High - unique, tailored designs | Low - uniform products |

| Production Volume | Low - limited pieces | High - mass quantities |

| Material Usage | Precise, minimal waste | Bulk, efficient but higher waste |

| Cost | Higher per piece due to labor | Lower per piece due to scale |

| Quality | Superior craftsmanship, unique finishes | Consistent, but less detailed |

| Lead Time | Longer - depends on complexity | Shorter - assembly line speed |

| Skill Level | High - skilled artisans required | Variable - machine operators |

Introduction to Jewelry Bench Work and Mass Production

Jewelry bench work involves handcrafted techniques where artisans meticulously shape, solder, and finish each piece, ensuring unique craftsmanship and attention to detail. Mass production in jewelry relies on automated processes such as casting, stamping, and molding to create large quantities of consistent designs, emphasizing efficiency and uniformity. Understanding the distinctions between these approaches helps jewelers choose the right method based on design complexity, production volume, and market demand.

Key Differences Between Bench Work and Mass Production

Bench work in jewelry making involves skilled artisans crafting each piece individually, allowing for intricate detailing and customization, while mass production relies on automated processes to produce large quantities efficiently and uniformly. Bench work emphasizes precision and artistic expression through hand tools and personal techniques, contrasting with mass production's use of molds, machinery, and standardized components. The key differences lie in production scale, craftsmanship level, and flexibility, with bench work suited for unique, high-quality pieces and mass production designed for volume and cost-effectiveness.

Skill Requirements: Artisans vs Assembly Line

Bench work in jewelry making demands highly skilled artisans proficient in intricate techniques such as stone setting, engraving, and soldering, ensuring each piece's uniqueness and quality. Mass production relies on assembly line workers executing repetitive tasks with efficiency and speed, requiring less specialized craftsmanship but emphasizing consistency and volume. The distinction in skill requirements fundamentally shapes the quality, customization, and artistic value of the final jewelry product.

Customization and Creativity in Bench Work

Bench work in jewelry making allows for unparalleled customization and creativity, enabling artisans to craft unique, one-of-a-kind pieces tailored to individual client specifications. Unlike mass production, bench work involves hands-on techniques such as hand carving, soldering, and stone setting, fostering innovation and intricate detailing that machines cannot replicate. This personalized approach results in exceptional craftsmanship and distinctive designs, appealing to customers seeking exclusive and meaningful jewelry.

Efficiency and Output in Mass Production

Mass production in jewelry making maximizes efficiency by utilizing automated processes and standardized components, significantly increasing output compared to traditional bench work. Advanced machinery enables rapid replication of designs, reducing manual labor time and improving consistency across large quantities. This method supports high-volume demand while maintaining quality, making it ideal for commercial jewelry brands aiming for scalability.

Material Quality Comparison

Bench work in jewelry making emphasizes meticulous craftsmanship using high-quality, often precious metals and gemstones, resulting in unique, durable pieces with superior material integrity. Mass production typically employs lower-grade materials or alloys to reduce costs and increase output, potentially compromising the longevity and value of the jewelry. The choice between bench work and mass production significantly impacts the overall quality and aesthetic appeal due to differences in material sourcing and handling.

Cost Implications for Businesses

Bench work in jewelry making involves skilled artisans crafting pieces individually, resulting in higher labor costs but allowing for customization and premium pricing. Mass production utilizes automated processes and standardized components, significantly reducing per-unit costs and enabling economies of scale for businesses. Choosing between bench work and mass production directly impacts overhead expenses, pricing strategies, and profit margins in the jewelry industry.

Market Demand and Target Customers

Bench work in jewelry making caters to niche markets seeking bespoke, handcrafted pieces with intricate details and unique designs, appealing to clients valuing exclusivity and artisanal quality. Mass production targets a broader customer base by offering affordable, trend-driven jewelry with faster turnaround, meeting high market demand for accessible fashion accessories. Understanding these distinctions allows jewelers to align their production methods with specific consumer preferences and market dynamics.

Sustainability and Environmental Impact

Bench work in jewelry making promotes sustainability by minimizing waste through careful material use and allowing for repairs that extend the life of pieces. Mass production often relies on energy-intensive processes and generates significant metal scraps and chemical byproducts, increasing environmental impact. Choosing bench work supports eco-friendly practices by emphasizing handcrafted quality and resource conservation in jewelry creation.

Which Method Suits Your Jewelry Business?

Bench work offers unparalleled precision and customization, ideal for artisans seeking unique, high-quality pieces that showcase intricate craftsmanship. Mass production excels in efficiency and cost-effectiveness, perfect for businesses targeting large markets with standard designs and faster turnaround times. Assess your brand's goals, target audience, and design complexity to determine whether personalized artistry or scalable volume best suits your jewelry business.

Bench work vs mass production Infographic

bizdif.com

bizdif.com