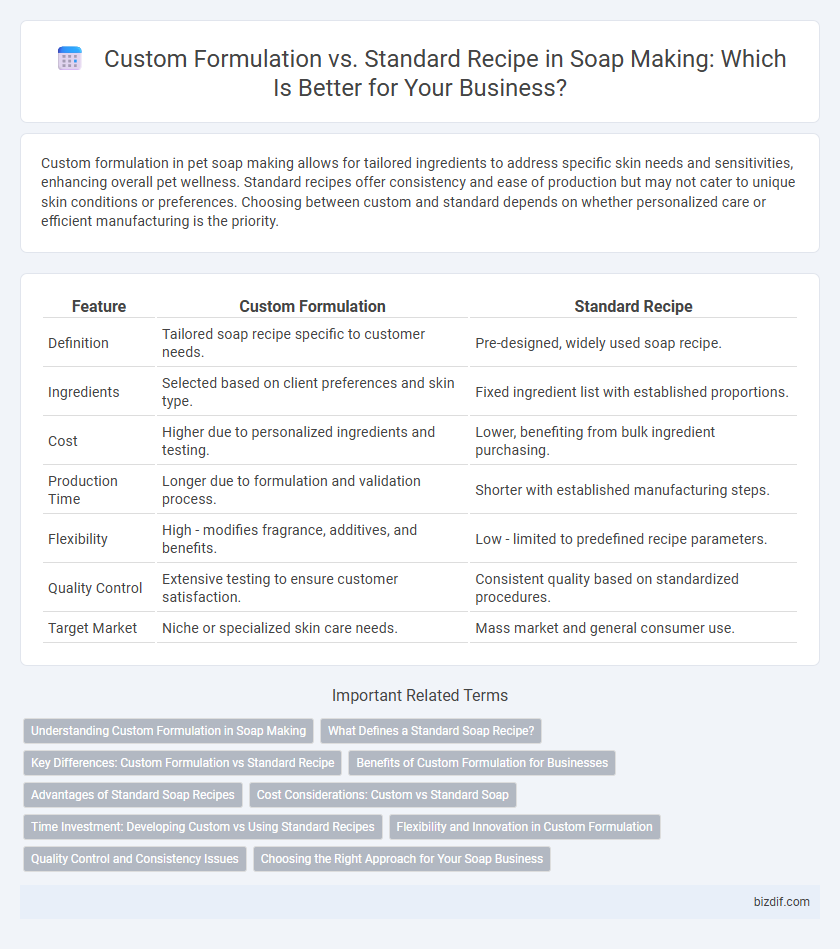

Custom formulation in pet soap making allows for tailored ingredients to address specific skin needs and sensitivities, enhancing overall pet wellness. Standard recipes offer consistency and ease of production but may not cater to unique skin conditions or preferences. Choosing between custom and standard depends on whether personalized care or efficient manufacturing is the priority.

Table of Comparison

| Feature | Custom Formulation | Standard Recipe |

|---|---|---|

| Definition | Tailored soap recipe specific to customer needs. | Pre-designed, widely used soap recipe. |

| Ingredients | Selected based on client preferences and skin type. | Fixed ingredient list with established proportions. |

| Cost | Higher due to personalized ingredients and testing. | Lower, benefiting from bulk ingredient purchasing. |

| Production Time | Longer due to formulation and validation process. | Shorter with established manufacturing steps. |

| Flexibility | High - modifies fragrance, additives, and benefits. | Low - limited to predefined recipe parameters. |

| Quality Control | Extensive testing to ensure customer satisfaction. | Consistent quality based on standardized procedures. |

| Target Market | Niche or specialized skin care needs. | Mass market and general consumer use. |

Understanding Custom Formulation in Soap Making

Custom formulation in soap making allows artisans to tailor ingredients, scent, texture, and skin benefits specifically to individual preferences or skin types, providing a unique and personalized product. This process involves adjusting the ratios of oils, lye, and additives such as essential oils or botanicals, enabling control over moisturizing properties and hardness of the soap. Understanding custom formulation empowers soap makers to innovate and create specialized products that meet niche market demands or personal skincare needs.

What Defines a Standard Soap Recipe?

A standard soap recipe is defined by a fixed ratio of oils, lye, and water that consistently produces a balanced bar with predictable hardness, lather, and moisturizing properties. These recipes rely on commonly used oils such as olive, coconut, and palm oil, ensuring reliable saponification and user experience. Standard recipes simplify production and quality control, making them ideal for beginners and large-scale soap manufacture.

Key Differences: Custom Formulation vs Standard Recipe

Custom formulation in soap making allows precise control over ingredients, enabling tailored properties such as scent, texture, and skin benefits, unlike standard recipes that follow fixed ingredient ratios. Standard recipes offer consistency and simplicity, ensuring reliable results ideal for beginners or mass production. Key differences lie in flexibility, customization potential, and suitability for specific skin types or market demands.

Benefits of Custom Formulation for Businesses

Custom formulation in soap making allows businesses to create unique products tailored to specific customer preferences, enhancing brand differentiation and loyalty. It enables precise control over ingredient quality and quantities, improving product performance and meeting regulatory standards more effectively. This flexibility supports innovation and responsiveness to market trends, driving competitive advantage and increased profitability.

Advantages of Standard Soap Recipes

Standard soap recipes offer consistent results by using proven ingredient ratios that ensure balanced cleansing and moisturizing properties. They simplify the soap-making process, making it easier for beginners to achieve high-quality bars without extensive testing or adjustments. Cost efficiency is also enhanced, as standard recipes minimize ingredient waste and reduce trial-and-error expenses.

Cost Considerations: Custom vs Standard Soap

Custom soap formulations typically incur higher costs due to specialized ingredients, tailored processes, and smaller production scales, making them less economical for mass production. Standard soap recipes benefit from bulk purchasing of common raw materials and streamlined manufacturing, resulting in significantly lower per-unit costs. Businesses must weigh the premium price of custom formulations against the cost-efficiency and consistency offered by standard recipes to meet budget and market demands effectively.

Time Investment: Developing Custom vs Using Standard Recipes

Developing a custom soap formulation requires a significant time investment for research, ingredient testing, and iterative adjustments to achieve desired qualities such as scent, texture, and skin benefits. In contrast, using a standard recipe drastically reduces production time by relying on proven ingredient ratios and methods, allowing for quicker batch creation and consistency across products. Time spent on custom formulations can lead to unique, tailored soaps, but standardized recipes are ideal for efficiency and uniform results in soap making.

Flexibility and Innovation in Custom Formulation

Custom formulation in soap making offers unparalleled flexibility, allowing artisans to tailor ingredients, scents, and textures to meet specific skin types and customer preferences. This approach fosters innovation by enabling experimentation with unique combinations of oils, additives, and essential oils that standard recipes often lack. Emphasizing personalization, custom formulations drive the creation of distinctive, high-quality soaps that stand out in a competitive market.

Quality Control and Consistency Issues

Custom formulation in soap making allows for tailored ingredient combinations to address specific skin needs, but it often introduces variability that challenges quality control and consistency. Standard recipes benefit from established ratios and tested processes, ensuring uniform texture, fragrance, and cleansing properties across batches. Maintaining stringent quality control protocols is essential when experimenting with custom formulations to prevent fluctuations in pH, lather formation, and hardness, which can impact product performance and consumer satisfaction.

Choosing the Right Approach for Your Soap Business

Choosing between custom formulation and standard recipes in soap making hinges on your business goals and target market preferences. Custom formulation offers unique, tailored products that can differentiate your brand and meet specific customer needs, while standard recipes ensure consistency, ease of production, and cost efficiency. Evaluating factors such as ingredient sourcing, production scale, and consumer demand will guide the decision to maximize profitability and brand loyalty.

Custom Formulation vs Standard Recipe Infographic

bizdif.com

bizdif.com