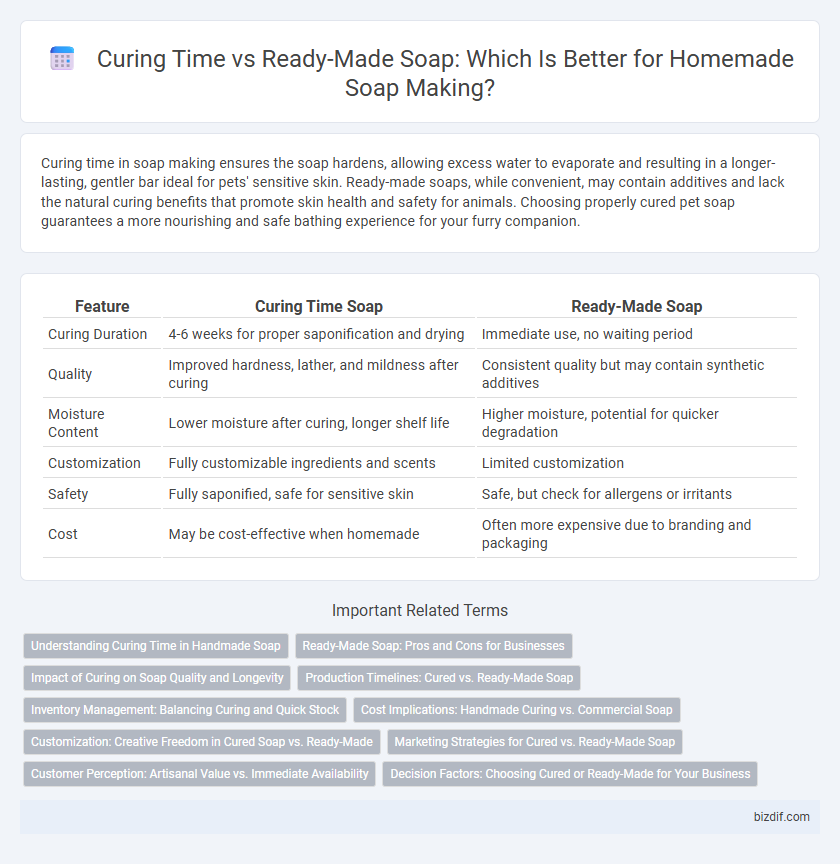

Curing time in soap making ensures the soap hardens, allowing excess water to evaporate and resulting in a longer-lasting, gentler bar ideal for pets' sensitive skin. Ready-made soaps, while convenient, may contain additives and lack the natural curing benefits that promote skin health and safety for animals. Choosing properly cured pet soap guarantees a more nourishing and safe bathing experience for your furry companion.

Table of Comparison

| Feature | Curing Time Soap | Ready-Made Soap |

|---|---|---|

| Curing Duration | 4-6 weeks for proper saponification and drying | Immediate use, no waiting period |

| Quality | Improved hardness, lather, and mildness after curing | Consistent quality but may contain synthetic additives |

| Moisture Content | Lower moisture after curing, longer shelf life | Higher moisture, potential for quicker degradation |

| Customization | Fully customizable ingredients and scents | Limited customization |

| Safety | Fully saponified, safe for sensitive skin | Safe, but check for allergens or irritants |

| Cost | May be cost-effective when homemade | Often more expensive due to branding and packaging |

Understanding Curing Time in Handmade Soap

Curing time is essential in handmade soap production, typically lasting 4 to 6 weeks to allow excess water to evaporate, resulting in a harder, longer-lasting bar. This natural drying process enhances the soap's lather, mildness, and cleansing properties compared to ready-made soaps often containing synthetic additives and moisture retainers. Understanding the curing phase ensures improved soap quality and skin benefits, highlighting the craftsmanship behind handmade soap making.

Ready-Made Soap: Pros and Cons for Businesses

Ready-made soap offers businesses immediate product availability, reducing inventory holding costs and accelerating cash flow. However, it limits customization options and can reduce brand differentiation in competitive markets. Profit margins may be lower due to wholesale pricing and lack of unique formulations tailored to target customer preferences.

Impact of Curing on Soap Quality and Longevity

Curing time significantly enhances soap quality by allowing excess water to evaporate, resulting in a harder, longer-lasting bar that produces a richer lather. Ready-made soaps often contain excess moisture, leading to softer bars that wear down quickly and may irritate sensitive skin. Properly cured soap balances pH and ensures complete saponification, improving both user experience and shelf life.

Production Timelines: Cured vs. Ready-Made Soap

Curing time significantly impacts production timelines, with cured soap typically requiring 4 to 6 weeks for the saponification process to complete and moisture to evaporate, resulting in a harder, longer-lasting bar. Ready-made soaps bypass this extended curing period, allowing for immediate packaging and sale, but often sacrifice durability and mildness. Manufacturers must balance the faster turnover of ready-made options against the superior quality and shelf life offered by properly cured soap.

Inventory Management: Balancing Curing and Quick Stock

Proper inventory management in soap making requires balancing the 4 to 6 weeks curing time that enhances soap hardness and mildness with the immediate availability of ready-made products for quick stock turnover. Maintaining this equilibrium helps prevent overstocking aged inventory while ensuring fresh, customer-ready bars are consistently on hand. Efficiently tracking curing batches and forecasting demand optimizes production schedules and minimizes storage costs.

Cost Implications: Handmade Curing vs. Commercial Soap

Handmade soap requires a curing time of 4 to 6 weeks to allow excess water to evaporate, ensuring hardness and longevity, which increases upfront labor and storage costs. In contrast, ready-made commercial soaps are produced rapidly using synthetic additives, significantly reducing production time and cost but often compromising natural ingredient benefits. The extended curing process in handmade soap results in a higher price point due to quality and time investment, whereas commercial soaps offer affordability at the expense of natural curing advantages.

Customization: Creative Freedom in Cured Soap vs. Ready-Made

Cured soap offers extended customization options, allowing artisans to experiment with unique ingredient blends, scents, and textures that develop fully during the 4 to 6-week curing process. In contrast, ready-made soaps provide limited personalization, as their formulations are fixed and mass-produced for consistency. The curing time enables creative freedom to craft bespoke soaps tailored to specific skin needs and aesthetic preferences, enhancing both quality and uniqueness.

Marketing Strategies for Cured vs. Ready-Made Soap

Highlighting the natural curing process in soap marketing emphasizes product quality, skin benefits, and longevity, appealing to health-conscious consumers seeking artisanal or organic products. Ready-made soaps can be marketed with a focus on convenience, immediate use, and variety, attracting buyers prioritizing speed and accessibility. Effective strategies balance educating customers on the benefits of cured soap's richer lather and moisturizing properties against promoting ready-made options for quick, hassle-free skincare solutions.

Customer Perception: Artisanal Value vs. Immediate Availability

Curing time in soap making enhances artisanal value by allowing chemical processes to complete, resulting in a harder, longer-lasting bar favored by customers seeking natural quality. Ready-made soaps offer immediate availability but may lack the depth of texture and mildness associated with properly cured batches. Customers often perceive cured soaps as premium and handmade, prioritizing craftsmanship over instant use.

Decision Factors: Choosing Cured or Ready-Made for Your Business

Curing time in soap making typically ranges from 4 to 6 weeks, allowing excess water to evaporate and the soap to harden, resulting in a longer-lasting, milder product with better lather and skin benefits. Ready-made soaps offer immediate availability but may lack the full quality and durability achieved through proper curing, impacting customer satisfaction and repurchase rates. Businesses must weigh factors such as production speed, product quality, inventory management, and target market preferences when deciding between cured or ready-made soap products.

Curing Time vs Ready-Made Infographic

bizdif.com

bizdif.com