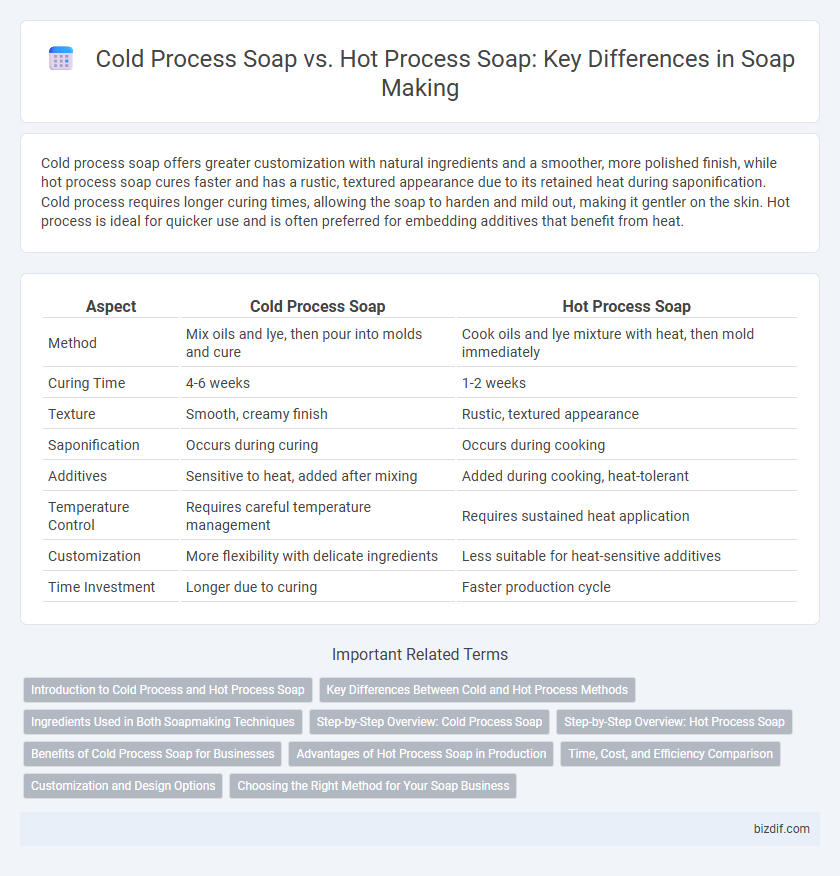

Cold process soap offers greater customization with natural ingredients and a smoother, more polished finish, while hot process soap cures faster and has a rustic, textured appearance due to its retained heat during saponification. Cold process requires longer curing times, allowing the soap to harden and mild out, making it gentler on the skin. Hot process is ideal for quicker use and is often preferred for embedding additives that benefit from heat.

Table of Comparison

| Aspect | Cold Process Soap | Hot Process Soap |

|---|---|---|

| Method | Mix oils and lye, then pour into molds and cure | Cook oils and lye mixture with heat, then mold immediately |

| Curing Time | 4-6 weeks | 1-2 weeks |

| Texture | Smooth, creamy finish | Rustic, textured appearance |

| Saponification | Occurs during curing | Occurs during cooking |

| Additives | Sensitive to heat, added after mixing | Added during cooking, heat-tolerant |

| Temperature Control | Requires careful temperature management | Requires sustained heat application |

| Customization | More flexibility with delicate ingredients | Less suitable for heat-sensitive additives |

| Time Investment | Longer due to curing | Faster production cycle |

Introduction to Cold Process and Hot Process Soap

Cold process soap involves mixing oils and lye solution at room temperature, allowing saponification to occur slowly, which preserves delicate ingredients and results in a smooth, creamy texture. Hot process soap uses external heat to accelerate saponification, creating a textured, rustic appearance with a shorter curing time due to the heat-driven chemical reaction. Both methods require precise measurements of oils, lye, and additives, but cold process offers more control over design detail while hot process is favored for faster usage.

Key Differences Between Cold and Hot Process Methods

Cold process soap involves mixing oils and lye at lower temperatures, preserving the natural glycerin and allowing for a smoother, more customizable texture. Hot process soap uses external heat to accelerate saponification, resulting in a faster cure time and a rustic, dense texture. The key differences lie in curing duration, texture, and the level of control over additives and colors.

Ingredients Used in Both Soapmaking Techniques

Cold process soap and hot process soap both utilize a blend of oils or fats such as olive oil, coconut oil, and palm oil, combined with lye (sodium hydroxide) for saponification. The primary distinction in ingredients lies in the hot process method often incorporating pre-cooked soap batter, allowing for the addition of heat-sensitive additives like essential oils and botanicals after saponification. Both techniques can customize ingredients to manipulate lather quality, moisturizing properties, and hardness by varying oil types and quantities.

Step-by-Step Overview: Cold Process Soap

Cold process soap making involves mixing lye and oils at room temperature, allowing saponification to occur naturally over several weeks. The mixture is blended until it reaches trace, then poured into molds to harden and cure for 4 to 6 weeks to achieve optimal hardness and mildness. This method preserves delicate fragrances and natural additives better than hot process, resulting in a smooth, customizable bar of soap.

Step-by-Step Overview: Hot Process Soap

Hot process soap involves blending oils and lye, then cooking the mixture in a slow cooker or double boiler until it reaches gel phase, typically taking 1 to 2 hours. After cooking, the soap batter is poured into molds and allowed to cure for 4 to 6 weeks to develop hardness and mildness. This method accelerates saponification compared to cold process soap, resulting in a faster, more textured soap ready for use sooner.

Benefits of Cold Process Soap for Businesses

Cold process soap offers businesses superior control over ingredients, allowing the creation of customized, high-quality products that appeal to niche markets. Its extended curing time results in a harder, longer-lasting bar, reducing customer complaints and return rates. The handcrafted appeal and natural aesthetic of cold process soap enhance brand value and justify premium pricing.

Advantages of Hot Process Soap in Production

Hot process soap offers faster curing times, allowing manufacturers to produce and distribute products more quickly compared to cold process soap. The heat applied during hot process soap making ensures complete saponification before molding, which reduces the risk of lye pockets and improves product safety and consistency. This method also allows for easier customization with additives like exfoliants or essential oils, as the soap base is more stable and less prone to separation.

Time, Cost, and Efficiency Comparison

Cold process soap requires a curing time of 4 to 6 weeks, while hot process soap can be used within 24 to 48 hours, making hot process significantly more time-efficient. Cost-wise, cold process soap utilizes less energy, relying on ambient temperatures during saponification, whereas hot process consumes more energy due to prolonged heating. Efficiency in cold process offers greater control over ingredients and detailed designs, whereas hot process is favored for faster batch turnover and more rustic textures.

Customization and Design Options

Cold process soap allows greater customization with intricate designs, swirls, and embedded objects due to its longer curing time and pliable batter. Hot process soap, while faster to cure, offers limited design options as the soap batter thickens quickly, restricting detailed patterns but enabling textured, rustic finishes. Both methods support essential oil and colorant customization but cold process excels in artistic expression and delicate aesthetics.

Choosing the Right Method for Your Soap Business

Cold process soap offers greater customization with intricate designs and smoother textures, ideal for artisan soap businesses targeting niche markets. Hot process soap cures faster, enabling quicker production cycles and consistent, rustic textures that appeal to handmade soap consumers seeking natural, chemical-free products. Selecting between cold and hot process methods depends on your business's production scale, desired aesthetics, and customer preferences for curing time and texture.

Cold Process Soap vs Hot Process Soap Infographic

bizdif.com

bizdif.com