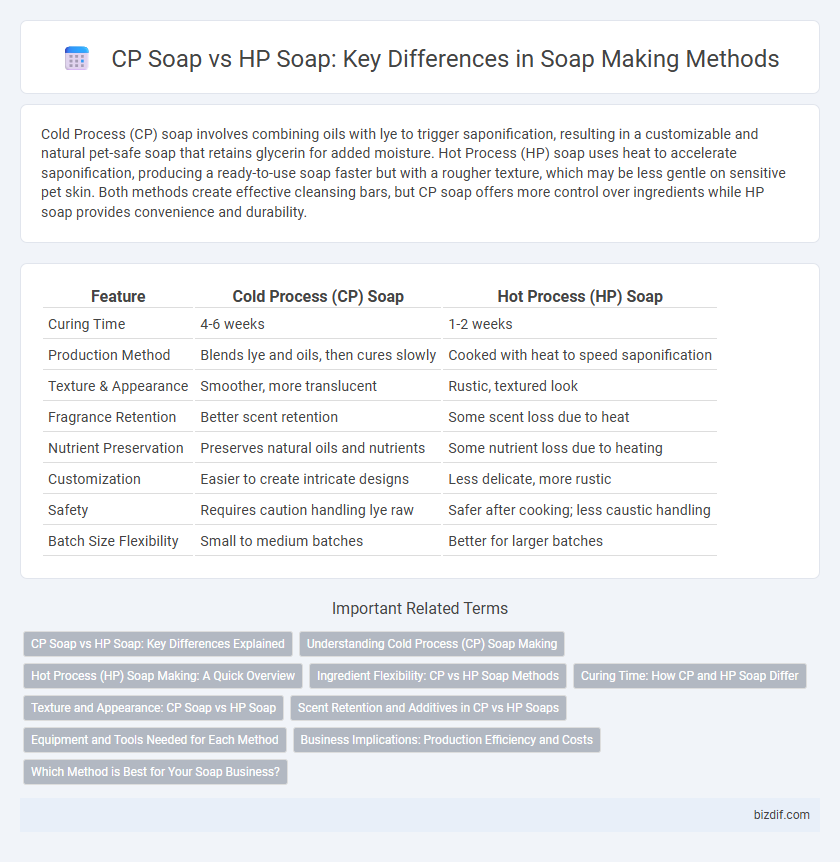

Cold Process (CP) soap involves combining oils with lye to trigger saponification, resulting in a customizable and natural pet-safe soap that retains glycerin for added moisture. Hot Process (HP) soap uses heat to accelerate saponification, producing a ready-to-use soap faster but with a rougher texture, which may be less gentle on sensitive pet skin. Both methods create effective cleansing bars, but CP soap offers more control over ingredients while HP soap provides convenience and durability.

Table of Comparison

| Feature | Cold Process (CP) Soap | Hot Process (HP) Soap |

|---|---|---|

| Curing Time | 4-6 weeks | 1-2 weeks |

| Production Method | Blends lye and oils, then cures slowly | Cooked with heat to speed saponification |

| Texture & Appearance | Smoother, more translucent | Rustic, textured look |

| Fragrance Retention | Better scent retention | Some scent loss due to heat |

| Nutrient Preservation | Preserves natural oils and nutrients | Some nutrient loss due to heating |

| Customization | Easier to create intricate designs | Less delicate, more rustic |

| Safety | Requires caution handling lye raw | Safer after cooking; less caustic handling |

| Batch Size Flexibility | Small to medium batches | Better for larger batches |

CP Soap vs HP Soap: Key Differences Explained

Cold Process (CP) soap and Hot Process (HP) soap differ primarily in their curing methods and texture. CP soap undergoes a slow saponification at room temperature, resulting in a smoother, more customizable bar with a longer curing time of 4-6 weeks. HP soap is cooked at higher temperatures, accelerating saponification and producing a rustic, thicker bar that can be used sooner, typically after 1-2 weeks of curing.

Understanding Cold Process (CP) Soap Making

Cold Process (CP) soap making involves mixing oils and lye without external heat, allowing saponification to occur naturally, which preserves the beneficial properties of oils and additives. CP soap requires a curing period of 4 to 6 weeks for water evaporation and hardening, resulting in a longer-lasting, gentler bar compared to Hot Process (HP) soap. HP soap involves cooking the mixture, accelerating saponification but often resulting in a rougher texture and less control over the final product's quality.

Hot Process (HP) Soap Making: A Quick Overview

Hot Process (HP) soap making involves cooking the soap mixture after saponification to accelerate the curing time, resulting in a ready-to-use product within days compared to weeks for Cold Process (CP) soap. The heat in HP soap making allows for immediate saponification completion, producing a rustic texture and a more natural, earthy scent. This method is favored by artisans who prioritize quick batch turnaround and a robust, durable bar of soap.

Ingredient Flexibility: CP vs HP Soap Methods

Cold Process (CP) soap allows greater ingredient flexibility due to the ability to add delicate additives like essential oils, botanicals, and milk after saponification begins, preserving their properties. Hot Process (HP) soap involves cooking the soap batter, which limits the types of additives that can be used as heat may degrade sensitive ingredients. CP soap typically benefits from a wider range of fragrance and color options, while HP soap favors durability over ingredient sensitivity.

Curing Time: How CP and HP Soap Differ

Cold Process (CP) soap requires a curing time of 4 to 6 weeks to allow excess water to evaporate and the soap to harden, enhancing lather and durability. In contrast, Hot Process (HP) soap undergoes a heat phase that accelerates saponification, reducing curing time to about 1 to 2 weeks while still producing a mild, long-lasting bar. This difference in curing time affects production schedules and the final texture of the soap, with CP soap often yielding smoother bars and HP soap offering quicker use.

Texture and Appearance: CP Soap vs HP Soap

Cold Process (CP) soap typically has a smooth, creamy texture and a matte finish, allowing for intricate designs and vibrant colors due to the slow saponification process. Hot Process (HP) soap tends to have a rustic, slightly rough texture with a more opaque and handcrafted appearance because heat accelerates saponification, causing the soap to gel and sometimes crack on the surface. CP soap's aesthetic versatility contrasts with HP soap's sturdy, natural look, influencing their respective uses in artisanal and practical soap making.

Scent Retention and Additives in CP vs HP Soaps

Cold Process (CP) soap typically retains scent better than Hot Process (HP) soap due to lower temperatures used during saponification, which helps preserve essential oils and fragrance compounds. CP soap allows for a wider variety of additives, including delicate botanicals and exfoliants, as the longer curing time and gentle process minimize degradation. Conversely, HP soap's higher heat can diminish scent strength and restrict the use of heat-sensitive additives, though it provides a faster manufacturing turnaround.

Equipment and Tools Needed for Each Method

Cold Process (CP) soap making requires precise digital scales for accurate measurement of oils and lye, a heat-resistant mixing container, stick blender for emulsification, and silicone molds for shaping bars. Hot Process (HP) soap making demands similar equipment but additionally uses a slow cooker or double boiler for cooking the soap batter to complete saponification. Both methods also need safety gear such as gloves and goggles due to caustic lye handling, but HP soap making benefits from a more heat-resistant environment due to prolonged heating.

Business Implications: Production Efficiency and Costs

Cold Process (CP) soap offers greater control over formulation but demands longer curing times, impacting production efficiency and inventory costs. Hot Process (HP) soap shortens curing to hours, accelerating turnaround and reducing storage expenses, which benefits businesses with high volume demands. The choice between CP and HP soap affects operational costs, labor intensity, and scalability in competitive soap manufacturing environments.

Which Method is Best for Your Soap Business?

Cold Process (CP) soap offers full control over ingredients and customization, ideal for artisan soap businesses emphasizing natural, high-quality products. Hot Process (HP) soap accelerates curing time and allows for faster production cycles, benefiting businesses that prioritize efficiency and quicker inventory turnover. Choosing the best method depends on your business goals, whether emphasizing product uniqueness with CP or maximizing output speed with HP.

CP Soap vs HP Soap Infographic

bizdif.com

bizdif.com