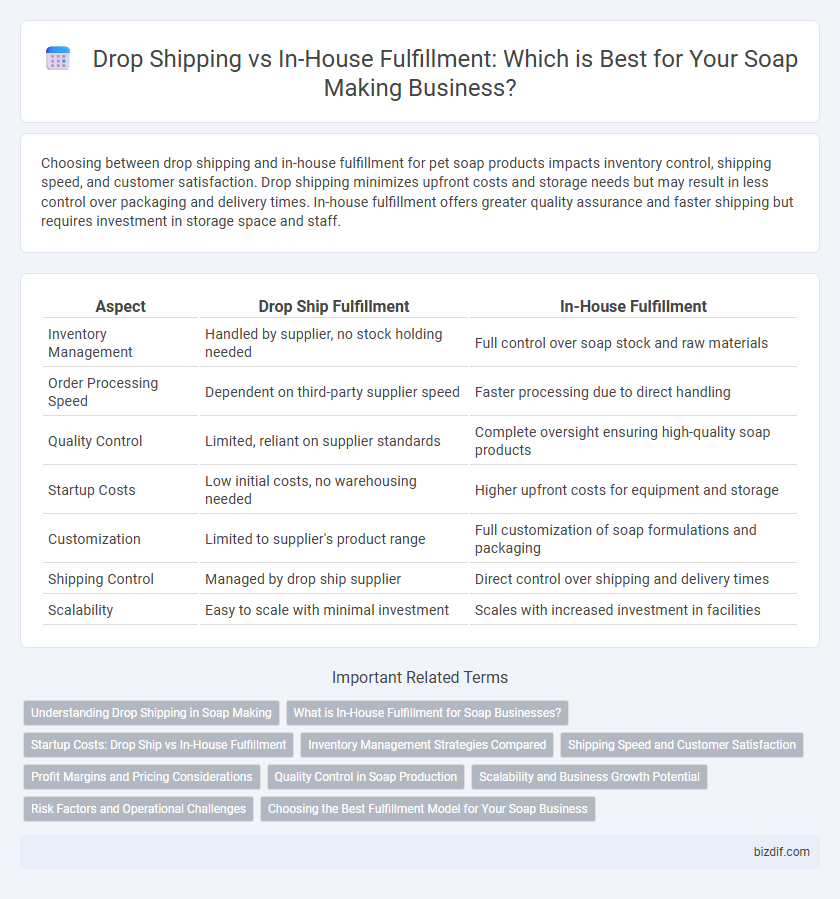

Choosing between drop shipping and in-house fulfillment for pet soap products impacts inventory control, shipping speed, and customer satisfaction. Drop shipping minimizes upfront costs and storage needs but may result in less control over packaging and delivery times. In-house fulfillment offers greater quality assurance and faster shipping but requires investment in storage space and staff.

Table of Comparison

| Aspect | Drop Ship Fulfillment | In-House Fulfillment |

|---|---|---|

| Inventory Management | Handled by supplier, no stock holding needed | Full control over soap stock and raw materials |

| Order Processing Speed | Dependent on third-party supplier speed | Faster processing due to direct handling |

| Quality Control | Limited, reliant on supplier standards | Complete oversight ensuring high-quality soap products |

| Startup Costs | Low initial costs, no warehousing needed | Higher upfront costs for equipment and storage |

| Customization | Limited to supplier's product range | Full customization of soap formulations and packaging |

| Shipping Control | Managed by drop ship supplier | Direct control over shipping and delivery times |

| Scalability | Easy to scale with minimal investment | Scales with increased investment in facilities |

Understanding Drop Shipping in Soap Making

Drop shipping in soap making allows artisans to sell products without maintaining inventory, relying on third-party suppliers to handle storage and shipping. This model reduces upfront costs and minimizes risk but requires careful selection of reliable suppliers to ensure product quality and timely delivery. Understanding the logistics, communication, and packaging standards of drop shipping is crucial for maintaining brand reputation and customer satisfaction in the competitive soap market.

What is In-House Fulfillment for Soap Businesses?

In-house fulfillment for soap businesses involves managing the entire production, packaging, and shipping process within the company's own facilities. This approach allows for greater control over product quality, customization, and inventory management specific to handcrafted or specialty soaps. By handling fulfillment internally, soap makers can ensure timely delivery and maintain consistent branding throughout the customer experience.

Startup Costs: Drop Ship vs In-House Fulfillment

Drop shipping minimizes startup costs by eliminating inventory purchase and warehousing expenses, allowing soap makers to launch with limited capital. In-house fulfillment requires investment in raw materials, storage space, packaging, and labor, increasing initial overhead for soap production businesses. Choosing drop shipping reduces financial risk for soap startups, while in-house fulfillment offers greater control with higher upfront costs.

Inventory Management Strategies Compared

Drop ship inventory management for soap making minimizes storage costs by relying on suppliers to ship products directly to customers, reducing capital tied up in stock. In-house fulfillment requires maintaining a well-organized inventory system to track raw materials like oils, lye, and fragrances, ensuring timely production and order accuracy. Efficient stock rotation and demand forecasting are essential in both methods to prevent ingredient spoilage and meet customer expectations promptly.

Shipping Speed and Customer Satisfaction

Drop ship soap making businesses often experience slower shipping speeds due to reliance on third-party suppliers, which can negatively impact customer satisfaction. In-house fulfillment allows greater control over inventory and shipping processes, resulting in faster delivery times and enhanced customer experience. Prioritizing in-house fulfillment can lead to higher repeat purchases and stronger brand loyalty through reliable and timely soap product deliveries.

Profit Margins and Pricing Considerations

In soap making, drop shipping reduces upfront costs but often results in lower profit margins due to higher per-unit prices and less control over wholesale pricing. In-house fulfillment increases operational expenses but allows for better pricing strategies and higher profit margins by controlling production and packaging costs. Careful analysis of sales volume, shipping logistics, and customer experience impacts pricing decisions and overall profitability in both models.

Quality Control in Soap Production

In soap production, quality control significantly benefits from in-house fulfillment by enabling direct oversight over ingredient sourcing, mixing, curing, and packaging processes. Drop shipping limits a producer's ability to inspect each batch, increasing the risk of inconsistencies in texture, scent, and ingredient potency. Maintaining strict quality control standards is critical for ensuring customer satisfaction and compliance with cosmetic safety regulations.

Scalability and Business Growth Potential

Drop shipping enables soap makers to scale quickly with minimal upfront investment by outsourcing inventory and shipping, allowing focus on marketing and product development. In-house fulfillment offers greater control over quality and branding but requires significant resources and infrastructure, potentially limiting rapid expansion. Choosing drop shipping supports faster business growth through flexible scalability, while in-house fulfillment may better suit established brands aiming for premium customer experience.

Risk Factors and Operational Challenges

Drop shipping in soap making reduces upfront inventory costs but introduces risks such as inconsistent product quality and delayed shipping times, affecting customer satisfaction. In-house fulfillment offers better quality control and faster turnaround but demands higher operational investments in storage, labor, and supply chain management. Balancing these options requires evaluating risks related to stockouts, shipping errors, and scalability to optimize the soap business's efficiency and reputation.

Choosing the Best Fulfillment Model for Your Soap Business

Choosing the best fulfillment model for your soap business involves evaluating cost, control, and scalability factors, where in-house fulfillment offers direct oversight and customization of packaging while drop shipping minimizes inventory risks and upfront investment. Assess order volume and customer expectations to determine whether in-house fulfillment's faster shipping and quality assurance outweigh drop shipping's convenience and reduced operational complexity. Prioritizing fulfillment speed, product quality, and profit margins ensures alignment with your soap brand's growth strategy and customer satisfaction goals.

Drop Ship vs In-House Fulfillment Infographic

bizdif.com

bizdif.com