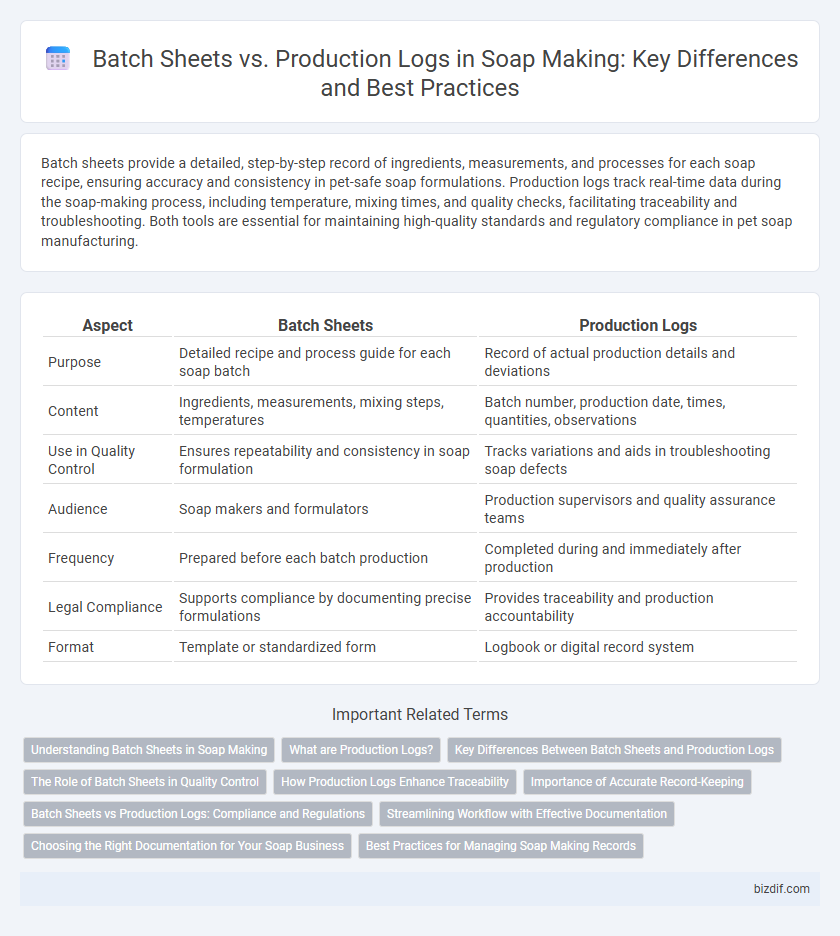

Batch sheets provide a detailed, step-by-step record of ingredients, measurements, and processes for each soap recipe, ensuring accuracy and consistency in pet-safe soap formulations. Production logs track real-time data during the soap-making process, including temperature, mixing times, and quality checks, facilitating traceability and troubleshooting. Both tools are essential for maintaining high-quality standards and regulatory compliance in pet soap manufacturing.

Table of Comparison

| Aspect | Batch Sheets | Production Logs |

|---|---|---|

| Purpose | Detailed recipe and process guide for each soap batch | Record of actual production details and deviations |

| Content | Ingredients, measurements, mixing steps, temperatures | Batch number, production date, times, quantities, observations |

| Use in Quality Control | Ensures repeatability and consistency in soap formulation | Tracks variations and aids in troubleshooting soap defects |

| Audience | Soap makers and formulators | Production supervisors and quality assurance teams |

| Frequency | Prepared before each batch production | Completed during and immediately after production |

| Legal Compliance | Supports compliance by documenting precise formulations | Provides traceability and production accountability |

| Format | Template or standardized form | Logbook or digital record system |

Understanding Batch Sheets in Soap Making

Batch sheets in soap making document precise ingredient measurements, mixing times, and processing conditions to ensure product consistency and traceability. They serve as a detailed recipe record critical for quality control, regulatory compliance, and replicability of soap batches. Unlike production logs, batch sheets emphasize formulation specifics rather than operational workflow data.

What are Production Logs?

Production logs are detailed records that document every step of the soap-making process, including ingredient quantities, batch numbers, temperatures, and curing times. These logs ensure traceability, quality control, and regulatory compliance throughout soap production. Maintaining accurate production logs helps identify issues, streamline workflows, and guarantee product consistency in artisanal and commercial soap making.

Key Differences Between Batch Sheets and Production Logs

Batch sheets in soap making provide detailed formulations, ingredient measurements, and process instructions for a single batch, ensuring consistency and repeatability. Production logs record actual production data, including batch numbers, quantities made, process deviations, and quality control checks, offering traceability and compliance documentation. While batch sheets guide manufacturing, production logs document execution, making both essential for efficient soap production management.

The Role of Batch Sheets in Quality Control

Batch sheets play a critical role in quality control during soap making by providing detailed documentation of each ingredient, precise measurements, and production steps for every batch. They ensure consistency, traceability, and accountability, allowing soap makers to identify and correct deviations in formulation or process quickly. By meticulously recording batch information, batch sheets facilitate compliance with safety standards and support quality assurance protocols.

How Production Logs Enhance Traceability

Production logs provide detailed, time-stamped records of each step during the soap making process, significantly enhancing traceability by allowing producers to track raw materials, formulations, and process variables. Unlike batch sheets, which offer a static summary, production logs capture dynamic operational data, enabling quick identification of deviations and facilitating quality control. This granular documentation supports regulatory compliance and improves overall product consistency and safety in soap manufacturing.

Importance of Accurate Record-Keeping

Accurate record-keeping in soap making ensures consistency in batch quality and compliance with safety and regulatory standards. Batch sheets capture detailed information about ingredients, quantities, and processing steps, enabling traceability and troubleshooting. Production logs document daily operations and equipment maintenance, supporting operational efficiency and accountability throughout the manufacturing process.

Batch Sheets vs Production Logs: Compliance and Regulations

Batch sheets and production logs are essential for meeting compliance and regulatory standards in soap making, with batch sheets providing detailed documentation of ingredient quantities, process steps, and quality control checkpoints for each batch. Production logs serve as real-time records capturing every action during manufacturing, ensuring traceability and accountability in accordance with Good Manufacturing Practices (GMP). Regulatory agencies often require both documents to verify consistency, safety, and adherence to approved formulations throughout the production lifecycle.

Streamlining Workflow with Effective Documentation

Batch sheets detail specific ingredient quantities, process steps, and equipment settings for each soap batch, ensuring consistency and quality control. Production logs record real-time data such as production time, temperature, and personnel involved, facilitating traceability and troubleshooting. Using both documents together streamlines workflow by improving accuracy, compliance, and operational efficiency in soap making.

Choosing the Right Documentation for Your Soap Business

Batch sheets provide detailed, step-by-step instructions and ingredient lists critical for maintaining consistency and quality control in soap making, ideal for small to medium-sized soap businesses. Production logs capture real-time data and adjustments during the soap-making process, offering a comprehensive record essential for scaling operations or ensuring regulatory compliance. Selecting the right documentation hinges on your business size, production scale, and the need for traceability or quality assurance in artisanal or commercial soap manufacturing.

Best Practices for Managing Soap Making Records

Batch sheets provide detailed, step-by-step records of soap recipes, ingredients, and processes, ensuring consistency and quality control in soap production. Production logs track the overall soap making workflow, including production dates, batch numbers, and equipment used, helping to monitor efficiency and traceability. Maintaining both documents with accurate, organized entries supports compliance with safety standards and facilitates troubleshooting during soap manufacturing.

Batch Sheets vs Production Logs Infographic

bizdif.com

bizdif.com