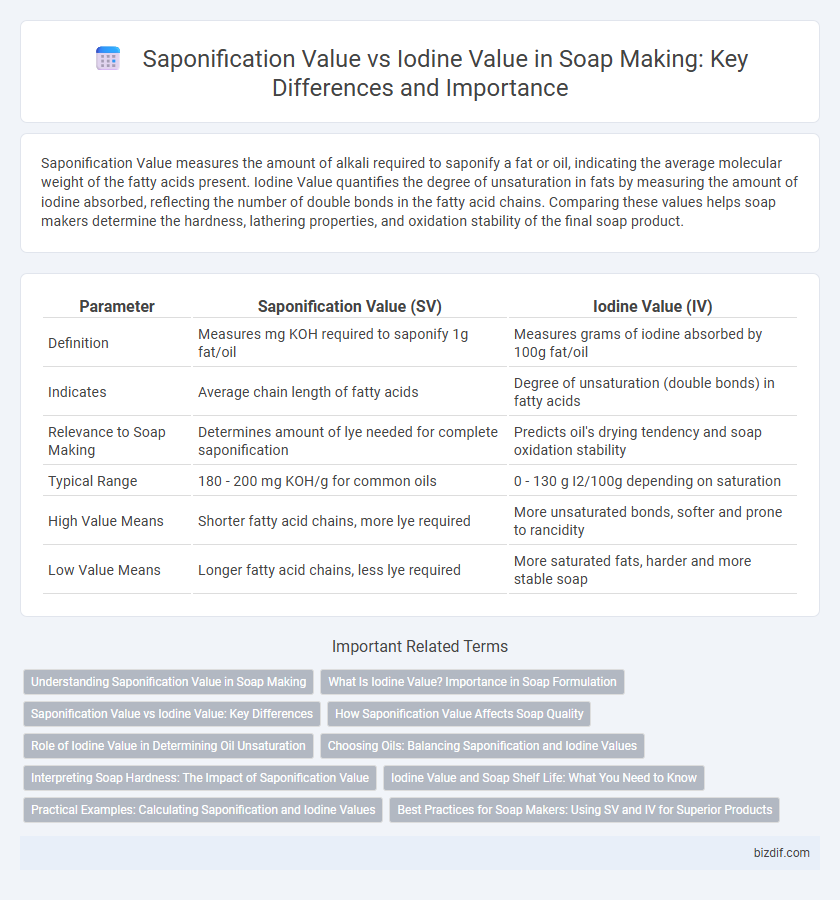

Saponification Value measures the amount of alkali required to saponify a fat or oil, indicating the average molecular weight of the fatty acids present. Iodine Value quantifies the degree of unsaturation in fats by measuring the amount of iodine absorbed, reflecting the number of double bonds in the fatty acid chains. Comparing these values helps soap makers determine the hardness, lathering properties, and oxidation stability of the final soap product.

Table of Comparison

| Parameter | Saponification Value (SV) | Iodine Value (IV) |

|---|---|---|

| Definition | Measures mg KOH required to saponify 1g fat/oil | Measures grams of iodine absorbed by 100g fat/oil |

| Indicates | Average chain length of fatty acids | Degree of unsaturation (double bonds) in fatty acids |

| Relevance to Soap Making | Determines amount of lye needed for complete saponification | Predicts oil's drying tendency and soap oxidation stability |

| Typical Range | 180 - 200 mg KOH/g for common oils | 0 - 130 g I2/100g depending on saturation |

| High Value Means | Shorter fatty acid chains, more lye required | More unsaturated bonds, softer and prone to rancidity |

| Low Value Means | Longer fatty acid chains, less lye required | More saturated fats, harder and more stable soap |

Understanding Saponification Value in Soap Making

Saponification Value measures the amount of alkali required to completely saponify a fat or oil, directly influencing soap hardness and cleansing power. A high Saponification Value indicates a greater proportion of short-chain fatty acids, enhancing lather and solubility, while a low value correlates with softer, conditioning soap bars. Understanding Saponification Value is essential for formulating balanced soaps by accurately calculating lye quantities to ensure complete oil conversion and optimal product quality.

What Is Iodine Value? Importance in Soap Formulation

Iodine Value measures the degree of unsaturation in fats and oils used for soap making by quantifying the amount of iodine absorbed per 100 grams of fat. This parameter is crucial in soap formulation because a higher iodine value indicates more unsaturated bonds, which correlate with softer, less stable soap bars prone to quicker rancidity. Understanding the iodine value helps soap makers balance hardness, lather quality, and shelf life by selecting oils that complement desired soap characteristics alongside the saponification value.

Saponification Value vs Iodine Value: Key Differences

Saponification Value measures the amount of alkali needed to saponify a fat or oil, indicating the average molecular weight of the fatty acids, while Iodine Value quantifies the degree of unsaturation in the fat or oil by measuring iodine absorption. High Saponification Values suggest shorter-chain fatty acids, essential for predicting soap hardness and cleansing properties, whereas high Iodine Values indicate more unsaturated bonds, affecting oil stability and soap shelf life. Understanding the difference between Saponification Value and Iodine Value helps formulators balance soap texture, lather quality, and durability.

How Saponification Value Affects Soap Quality

Saponification value measures the amount of alkali required to saponify a fat or oil, directly influencing soap hardness and cleansing ability. Higher saponification values indicate shorter-chain fatty acids, leading to soaps that lather well but may be softer or more soluble. Controlling saponification value optimizes soap quality by balancing firmness, longevity, and moisturizing properties essential for effective soap formulation.

Role of Iodine Value in Determining Oil Unsaturation

Iodine value measures the degree of unsaturation in oils by quantifying the amount of iodine absorbed by double bonds in fatty acids, which is crucial for predicting soap hardness and oxidation stability. Oils with higher iodine values contain more unsaturated fatty acids, resulting in softer soaps with faster rancidity potential. Understanding iodine value helps soap makers select oils that balance durability and moisturizing properties in the final product.

Choosing Oils: Balancing Saponification and Iodine Values

Choosing oils for soap making requires balancing saponification value, which indicates the amount of lye needed to fully saponify a given oil, with iodine value, representing the degree of unsaturation and softness in the final soap. Oils with high saponification values demand more lye and yield harder soaps, while higher iodine values contribute to softer, more conditioning bars but may reduce shelf life. Optimal soap formulation hinges on selecting oils that provide a balance between these values to achieve desired soap hardness, lather quality, and longevity.

Interpreting Soap Hardness: The Impact of Saponification Value

Saponification value measures the amount of alkali required to saponify a fat or oil, directly influencing soap hardness by indicating the fatty acid chain length and saturation. Higher saponification values generally signify shorter chain fatty acids, resulting in harder soaps with better cleansing properties. In contrast, iodine value relates to unsaturation levels but plays a lesser role in determining soap hardness compared to saponification value.

Iodine Value and Soap Shelf Life: What You Need to Know

Iodine value measures the degree of unsaturation in oils and fats, directly impacting soap's oxidation rate and shelf life. Higher iodine values indicate more unsaturated bonds, making soaps prone to faster rancidity and shorter shelf stability. Understanding iodine value helps soap makers select oils that enhance product longevity by minimizing oxidation and extending shelf life.

Practical Examples: Calculating Saponification and Iodine Values

Calculating Saponification Value (SV) involves determining the amount of potassium hydroxide (KOH) required to saponify a fat or oil sample, typically measured in mg KOH per gram of fat, to assess soap yield and quality. Iodine Value (IV) quantifies the degree of unsaturation in fats or oils, given in grams of iodine absorbed per 100 grams of sample, which influences the hardness and shelf life of soap. For practical soap making, combining SV and IV calculations guides formulators in selecting oils that balance lather properties, hardness, and stability in the final soap product.

Best Practices for Soap Makers: Using SV and IV for Superior Products

Saponification Value (SV) measures the amount of alkali needed to fully saponify a specific fat or oil, guiding soap makers in accurately balancing lye for optimal hardness and lather quality. Iodine Value (IV) indicates the degree of unsaturation in oils, influencing the soap's moisturizing properties and oxidation stability. Combining SV and IV data enables artisans to select and blend oils precisely, ensuring superior soap texture, longevity, and skin compatibility.

Saponification Value vs Iodine Value Infographic

bizdif.com

bizdif.com