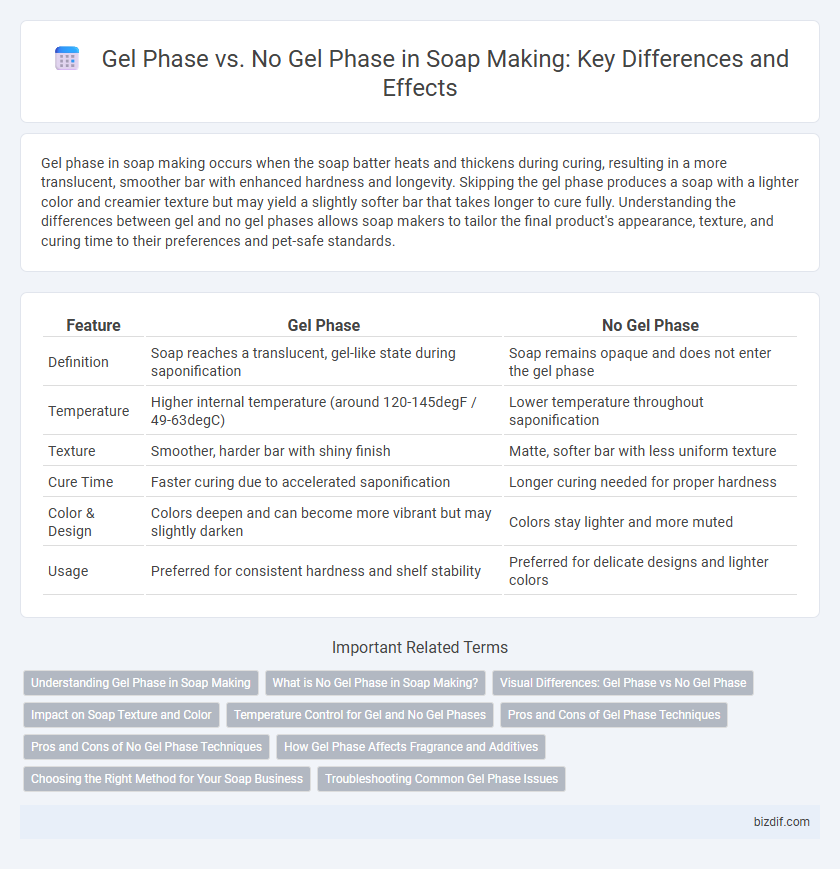

Gel phase in soap making occurs when the soap batter heats and thickens during curing, resulting in a more translucent, smoother bar with enhanced hardness and longevity. Skipping the gel phase produces a soap with a lighter color and creamier texture but may yield a slightly softer bar that takes longer to cure fully. Understanding the differences between gel and no gel phases allows soap makers to tailor the final product's appearance, texture, and curing time to their preferences and pet-safe standards.

Table of Comparison

| Feature | Gel Phase | No Gel Phase |

|---|---|---|

| Definition | Soap reaches a translucent, gel-like state during saponification | Soap remains opaque and does not enter the gel phase |

| Temperature | Higher internal temperature (around 120-145degF / 49-63degC) | Lower temperature throughout saponification |

| Texture | Smoother, harder bar with shiny finish | Matte, softer bar with less uniform texture |

| Cure Time | Faster curing due to accelerated saponification | Longer curing needed for proper hardness |

| Color & Design | Colors deepen and can become more vibrant but may slightly darken | Colors stay lighter and more muted |

| Usage | Preferred for consistent hardness and shelf stability | Preferred for delicate designs and lighter colors |

Understanding Gel Phase in Soap Making

Gel phase in soap making is a heat-driven process where the soap mixture reaches a translucent, jelly-like consistency as it heats internally, typically between 125degF and 180degF. This phase enhances soap clarity, accelerates saponification, and can produce a harder, more durable bar with improved color vibrancy. Absence of gel phase results in a soap that cools uniformly, maintaining a creamy, opaque appearance but with slower trace development and potentially softer texture.

What is No Gel Phase in Soap Making?

No gel phase in soap making occurs when the soap mixture remains cool during saponification, preventing the internal heat rise that causes gel phase. This results in soap with a more opaque and matte appearance, often producing a harder bar with less vibrant color. Soaps made without gel phase typically cure slower but tend to have a longer-lasting lather and more resilient texture.

Visual Differences: Gel Phase vs No Gel Phase

Gel phase in soap making results in a translucent, glossy appearance, often with enhanced color vibrancy and a warmer, slightly opaque center. Soaps that do not undergo gel phase tend to have a matte finish with more uniform, muted colors and a cooler, opaque texture throughout the loaf. Visual indicators of gel phase include a shiny surface and visible heat retention during curing, contrasting with the dull, cooler look of no gel phase soap.

Impact on Soap Texture and Color

Gel phase in soap making results in a warmer, denser texture with vibrant, deeper colors due to increased heat retention during saponification. Soaps that do not undergo gel phase tend to be harder and have a more opaque, muted appearance with a drier surface. Understanding the gel phase's influence helps artisans control the final soap's aesthetic and tactile qualities.

Temperature Control for Gel and No Gel Phases

Maintaining precise temperature control during soap making determines whether the mixture undergoes gel phase, with temperatures between 110degF and 130degF promoting gelation, resulting in a smoother, more translucent bar. Avoiding gel phase requires cooler temperatures below 100degF, preserving lighter colors and allowing for more pronounced swirl effects in soap aesthetics. Thermoregulation ensures consistency in texture, hardness, and curing time, critical for achieving desired soap qualities.

Pros and Cons of Gel Phase Techniques

Gel phase in soap making enhances color vibrancy and promotes a faster trace, resulting in a smoother texture and a more homogeneous bar. However, it can cause the soap to overheat, potentially leading to soap cracking or frosting, and may reduce the longevity of delicate additives like essential oils. Choosing gel phase techniques depends on the desired soap aesthetics and the sensitivity of ingredients involved.

Pros and Cons of No Gel Phase Techniques

No Gel Phase soap making preserves the natural marbling and mottled designs, offering a visually distinctive finish favored by artistic soapers. It reduces the risk of overheating, which helps maintain the integrity of heat-sensitive additives like essential oils and botanical extracts. However, skipping gel phase can result in a longer curing time and slightly harder soap bars, potentially affecting texture and lather quality.

How Gel Phase Affects Fragrance and Additives

Gel phase in soap making significantly influences fragrance retention and the behavior of additives by creating a more uniform, gelatinous structure that traps essential oils and scent molecules effectively. This phase enhances scent longevity and uniform distribution, preventing additives like herbs or exfoliants from settling or discoloring unevenly. Conversely, no gel phase may result in less vibrant fragrance and uneven additive placement, impacting the soap's overall aesthetic and olfactory quality.

Choosing the Right Method for Your Soap Business

Gel phase in soap making enhances translucency and color vibrancy, improving product aesthetics that attract customers. Skipping gel phase results in a milder, less glossy bar with a more natural look, appealing to eco-conscious markets. Selecting the right method depends on your brand's target audience, desired visual appeal, and production timeline to maximize market impact and customer satisfaction.

Troubleshooting Common Gel Phase Issues

Gel phase in soap making influences clarity, texture, and hardness of the final product; common issues include uneven gelation causing patchy appearance and inconsistent curing. Troubleshooting involves adjusting batter temperature, insulating molds adequately, and modifying lye concentration to promote uniform heat distribution and optimal gel formation. Avoiding rapid cooling and excessive water content also helps maintain proper gel phase, ensuring balanced saponification and smoother, more stable soap bars.

Gel Phase vs No Gel Phase Infographic

bizdif.com

bizdif.com