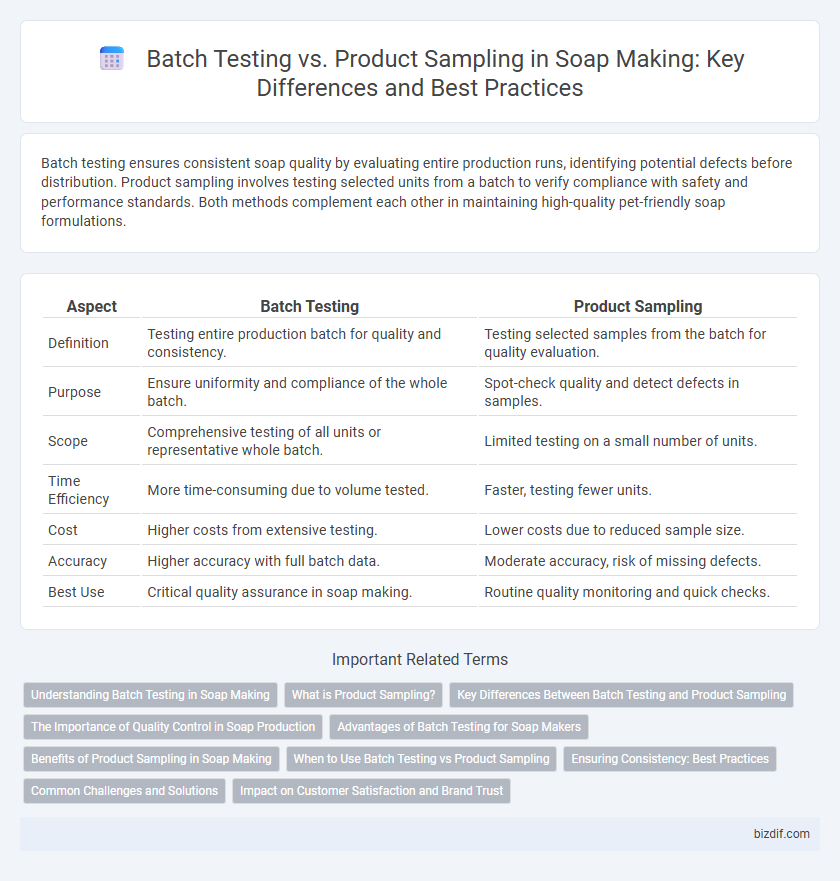

Batch testing ensures consistent soap quality by evaluating entire production runs, identifying potential defects before distribution. Product sampling involves testing selected units from a batch to verify compliance with safety and performance standards. Both methods complement each other in maintaining high-quality pet-friendly soap formulations.

Table of Comparison

| Aspect | Batch Testing | Product Sampling |

|---|---|---|

| Definition | Testing entire production batch for quality and consistency. | Testing selected samples from the batch for quality evaluation. |

| Purpose | Ensure uniformity and compliance of the whole batch. | Spot-check quality and detect defects in samples. |

| Scope | Comprehensive testing of all units or representative whole batch. | Limited testing on a small number of units. |

| Time Efficiency | More time-consuming due to volume tested. | Faster, testing fewer units. |

| Cost | Higher costs from extensive testing. | Lower costs due to reduced sample size. |

| Accuracy | Higher accuracy with full batch data. | Moderate accuracy, risk of missing defects. |

| Best Use | Critical quality assurance in soap making. | Routine quality monitoring and quick checks. |

Understanding Batch Testing in Soap Making

Batch testing in soap making involves analyzing a specific quantity of soap produced under controlled conditions to ensure consistency, safety, and quality standards are met before large-scale production or distribution. It typically includes assessing pH levels, texture, scent, and moisture content to detect any deviations that could affect product performance or user experience. Accurate batch testing minimizes variability, supports regulatory compliance, and enhances consumer trust in the soap products.

What is Product Sampling?

Product sampling in soap making involves selecting a representative portion of a soap batch to evaluate its quality, fragrance, texture, and performance before full-scale production or distribution. It helps identify any potential defects or inconsistencies, ensuring the final product meets brand standards and customer expectations. This process reduces waste and enhances quality control by allowing early adjustments based on real-time feedback.

Key Differences Between Batch Testing and Product Sampling

Batch testing in soap making involves analyzing an entire production batch to ensure consistency, safety, and quality standards, whereas product sampling tests only selected units from the batch for specific attributes. Batch testing is comprehensive and mandatory for regulatory compliance, focusing on uniformity across the entire batch, while product sampling is more efficient for routine quality checks and customer-specific requirements. Key differences include the scale of testing, regulatory implications, and the depth of quality assurance each method provides.

The Importance of Quality Control in Soap Production

Batch testing in soap production ensures each batch meets strict quality standards by analyzing parameters like pH, hardness, and lather consistency, preventing defects before distribution. Product sampling involves selecting finished units from a production line to verify consistency, fragrance retention, and color uniformity, serving as a final checkpoint for consumer safety and satisfaction. Effective quality control combines both methods to minimize variability, guarantee regulatory compliance, and maintain brand reputation in competitive soap manufacturing.

Advantages of Batch Testing for Soap Makers

Batch testing in soap making ensures consistent quality by thoroughly analyzing each production batch for pH balance, moisture content, and saponification completeness, reducing the risk of product defects. This method enables soap makers to identify variations early, maintain compliance with industry standards, and enhance overall safety and customer satisfaction. Compared to random product sampling, batch testing provides comprehensive data that supports reliable scaling and process optimization.

Benefits of Product Sampling in Soap Making

Product sampling in soap making enables real-time quality assessment, ensuring consistent texture, scent, and lather performance before full-scale production. This hands-on evaluation detects formulation discrepancies early, reducing waste and enhancing customer satisfaction by delivering reliably high-quality products. Sampling also facilitates direct feedback from testers, supporting continuous improvement and innovation in soap recipes.

When to Use Batch Testing vs Product Sampling

Batch testing is essential during the production phase to verify consistency, quality, and compliance of each soap batch before mass distribution, ensuring safety and formulation accuracy. Product sampling serves best in post-production scenarios for market feedback, assessing consumer satisfaction, and detecting potential issues in packaging or scent retention over time. Soap makers should use batch testing for regulatory adherence and quality control, while product sampling is ideal for gauging real-world product performance and consumer preferences.

Ensuring Consistency: Best Practices

Batch testing and product sampling are crucial for ensuring consistency in soap making by verifying uniformity in formulation, pH levels, and curing times across batches. Implementing standardized protocols for both methods enhances quality control and helps identify deviations early in production. Regular analysis using batch testing combined with random product sampling ensures that each soap batch meets established safety and performance standards.

Common Challenges and Solutions

Batch testing in soap making ensures consistency and quality by analyzing entire production batches, but it often faces challenges like time-consuming processes and resource intensity. Product sampling offers quicker feedback but risks unrepresentative results due to limited sample size and variability in soap formulations. Implementing standardized protocols and using statistical sampling methods can enhance reliability and address these common challenges in quality control.

Impact on Customer Satisfaction and Brand Trust

Batch testing in soap making ensures consistent product quality by identifying defects before distribution, which directly enhances customer satisfaction and reinforces brand trust. Product sampling allows customers to experience soap variants firsthand, increasing buyer confidence and reducing returns. Combining both strategies optimizes quality control and fosters long-term loyalty through reliable and appealing products.

Batch Testing vs Product Sampling Infographic

bizdif.com

bizdif.com