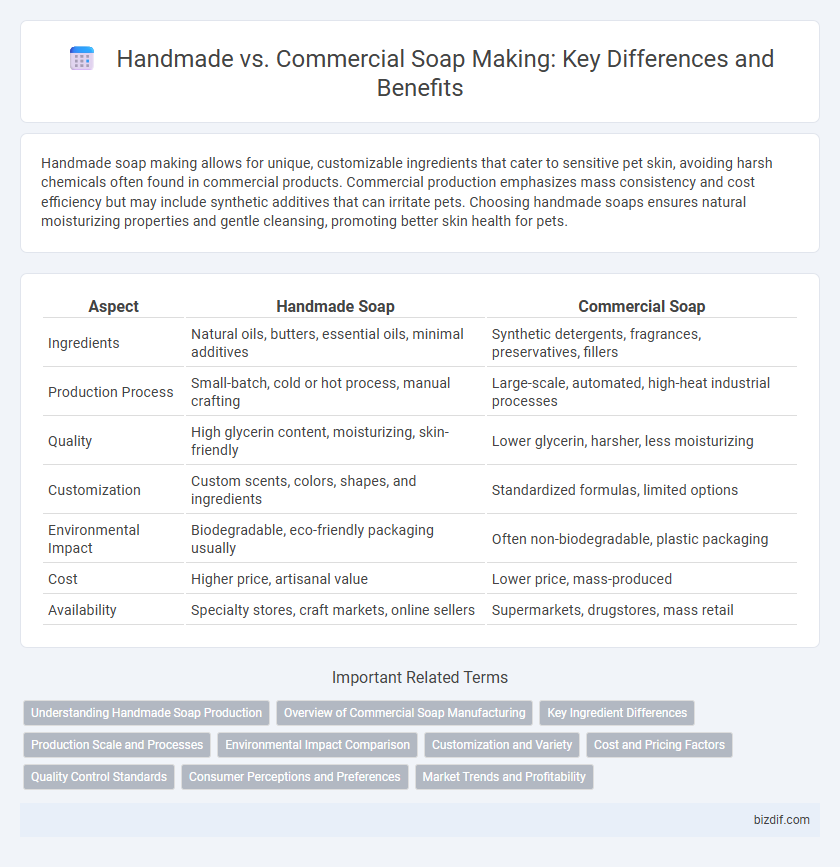

Handmade soap making allows for unique, customizable ingredients that cater to sensitive pet skin, avoiding harsh chemicals often found in commercial products. Commercial production emphasizes mass consistency and cost efficiency but may include synthetic additives that can irritate pets. Choosing handmade soaps ensures natural moisturizing properties and gentle cleansing, promoting better skin health for pets.

Table of Comparison

| Aspect | Handmade Soap | Commercial Soap |

|---|---|---|

| Ingredients | Natural oils, butters, essential oils, minimal additives | Synthetic detergents, fragrances, preservatives, fillers |

| Production Process | Small-batch, cold or hot process, manual crafting | Large-scale, automated, high-heat industrial processes |

| Quality | High glycerin content, moisturizing, skin-friendly | Lower glycerin, harsher, less moisturizing |

| Customization | Custom scents, colors, shapes, and ingredients | Standardized formulas, limited options |

| Environmental Impact | Biodegradable, eco-friendly packaging usually | Often non-biodegradable, plastic packaging |

| Cost | Higher price, artisanal value | Lower price, mass-produced |

| Availability | Specialty stores, craft markets, online sellers | Supermarkets, drugstores, mass retail |

Understanding Handmade Soap Production

Handmade soap production involves blending natural oils, lye, and additives through a cold or hot process, allowing for customization in ingredients and fragrances that enhance skin benefits. Unlike commercial soaps, handmade soaps retain glycerin, a natural moisturizer, and typically avoid synthetic detergents and harsh chemicals, resulting in a gentler product. Artisanal methods emphasize small-batch crafting and curing times that ensure superior quality, texture, and skin compatibility.

Overview of Commercial Soap Manufacturing

Commercial soap manufacturing involves large-scale production using automated machinery that ensures consistent quality and uniformity across batches. The process often incorporates synthetic detergents and additives to enhance lather, scent, and shelf life, contrasting with the natural ingredients typically found in handmade soaps. Efficiency and cost-effectiveness are prioritized, allowing mass distribution to a wide consumer base through various retail channels.

Key Ingredient Differences

Handmade soap production prioritizes natural ingredients such as essential oils, plant-based oils, and organic additives like herbs and clays, resulting in a product free from synthetic chemicals and preservatives. Commercial soaps often contain synthetic detergents, artificial fragrances, and stabilizers to enhance shelf life and reduce costs, which may affect skin sensitivity and environmental impact. The choice of key ingredients directly influences the soap's moisturizing properties, aroma, and overall skin compatibility.

Production Scale and Processes

Handmade soap production typically involves small-scale batches crafted using traditional methods like cold process or hot process, which allow for greater control over ingredient quality and customization. Commercial soap production operates on a large scale with automated systems and continuous processes, optimizing efficiency but often relying on synthetic additives and standardized formulations. The production scale significantly impacts product texture, ingredient sourcing, and environmental footprint.

Environmental Impact Comparison

Handmade soap production typically uses natural, biodegradable ingredients and small-batch processes that minimize waste and reduce energy consumption compared to commercial soap manufacturing. Commercial production often relies on synthetic chemicals and large-scale machinery, contributing to higher carbon emissions, water pollution, and plastic packaging waste. Choosing handmade soaps supports sustainable practices by reducing environmental footprints and promoting eco-friendly sourcing.

Customization and Variety

Handmade soap offers unparalleled customization, allowing artisans to tailor ingredients, scents, and textures to meet specific skin types and preferences. Commercial production emphasizes mass appeal and consistency, often limiting the variety of formulations available to consumers. Unique blends and specialty additives in handmade soaps support niche markets and personalized skincare needs that commercial products rarely address.

Cost and Pricing Factors

Handmade soap production involves higher raw material costs due to premium oils, natural additives, and small-batch processes, resulting in higher retail prices. Commercial production benefits from economies of scale, automated machinery, and synthetic ingredients, significantly reducing manufacturing expenses and enabling lower pricing. Consumers often pay a premium for handmade soaps because of artisanal quality, customization, and perceived natural benefits, despite the higher production costs.

Quality Control Standards

Handmade soap production emphasizes stringent quality control standards through small-batch monitoring, ensuring consistent ingredient quality and curing times that enhance natural benefits and skin compatibility. Commercial production relies on automated processes and standardized testing protocols to maintain uniformity and meet regulatory compliance across large volumes. Both methods implement quality assurance measures but differ in the scale, customization, and attention to artisanal detail.

Consumer Perceptions and Preferences

Handmade soap is often perceived by consumers as a higher-quality, natural alternative compared to commercial soap, emphasizing artisanal craftsmanship and unique ingredient blends. Preferences favor handmade soaps for their skin-friendly properties, absence of harsh chemicals, and environmental sustainability. Commercial soaps, while praised for affordability and consistency, may be viewed as less personalized and more synthetic by discerning buyers seeking niche benefits.

Market Trends and Profitability

Handmade soap production leverages unique, natural ingredients and artisanal techniques, catering to growing consumer demand for eco-friendly, personalized products, which drives higher market value and profit margins despite smaller batch sizes. Commercial soap production benefits from economies of scale and automated processes, resulting in lower costs per unit and widespread distribution but faces stiff competition and narrower profit margins. Current market trends indicate increased consumer preference for sustainable, handcrafted soaps, enhancing the profitability of artisan brands within niche markets.

Handmade vs Commercial Production Infographic

bizdif.com

bizdif.com