Curing time is essential in pet soap making to ensure the soap hardens properly, allowing excess water to evaporate and resulting in a longer-lasting, gentle product perfect for sensitive animal skin. Immediate sale after production can lead to a softer, less durable soap that may not provide the same cleansing or moisturizing benefits and could irritate delicate pet fur and skin. Prioritizing curing time enhances the soap's quality, effectiveness, and safety for pets.

Table of Comparison

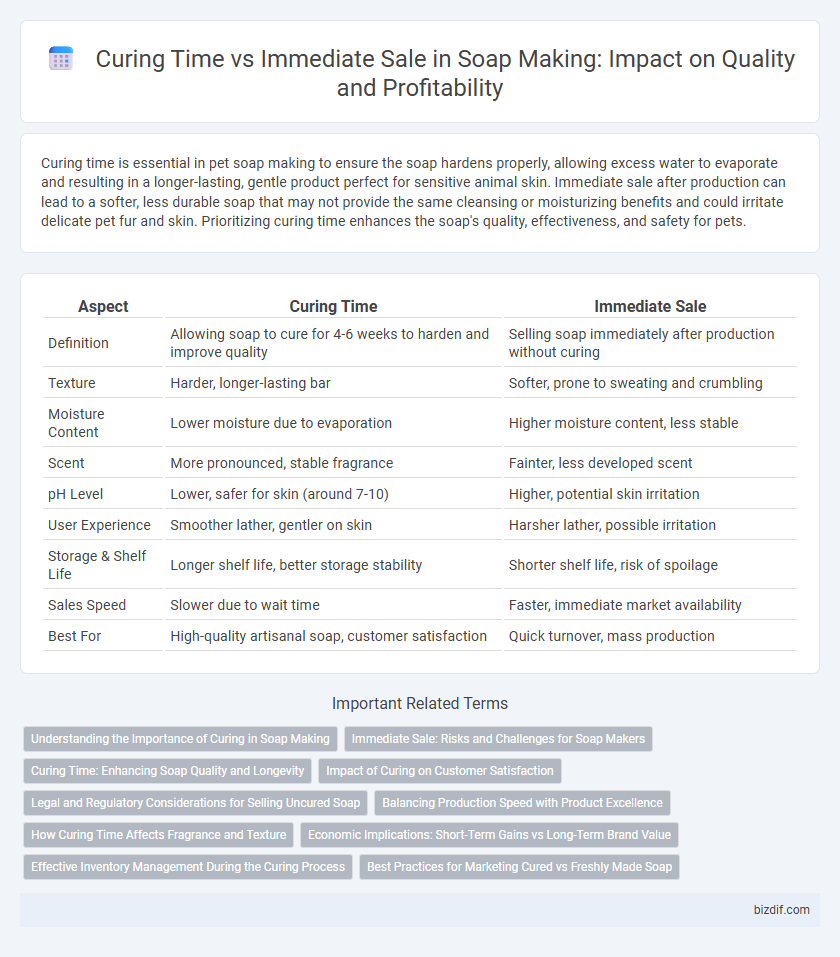

| Aspect | Curing Time | Immediate Sale |

|---|---|---|

| Definition | Allowing soap to cure for 4-6 weeks to harden and improve quality | Selling soap immediately after production without curing |

| Texture | Harder, longer-lasting bar | Softer, prone to sweating and crumbling |

| Moisture Content | Lower moisture due to evaporation | Higher moisture content, less stable |

| Scent | More pronounced, stable fragrance | Fainter, less developed scent |

| pH Level | Lower, safer for skin (around 7-10) | Higher, potential skin irritation |

| User Experience | Smoother lather, gentler on skin | Harsher lather, possible irritation |

| Storage & Shelf Life | Longer shelf life, better storage stability | Shorter shelf life, risk of spoilage |

| Sales Speed | Slower due to wait time | Faster, immediate market availability |

| Best For | High-quality artisanal soap, customer satisfaction | Quick turnover, mass production |

Understanding the Importance of Curing in Soap Making

Curing soap for 4 to 6 weeks allows excess water to evaporate, resulting in a harder, longer-lasting bar that produces a stable lather and gentle cleansing properties. Immediate sale of freshly made soap risks a softer texture and reduced durability due to incomplete saponification, affecting the soap's quality and customer satisfaction. Understanding the importance of curing in soap making ensures optimal product performance and enhances shelf life by promoting full chemical reaction and moisture reduction.

Immediate Sale: Risks and Challenges for Soap Makers

Selling soap immediately after production poses significant risks for soap makers, including incomplete saponification which can result in harsh, irritating products that damage customer trust. The lack of proper curing time also leads to excess moisture, causing soap to be soft, prone to disintegration, and reduced shelf life. This compromises product quality, risks negative reviews, and ultimately harms brand reputation and sales performance.

Curing Time: Enhancing Soap Quality and Longevity

Curing time in soap making allows excess water to evaporate, resulting in a harder, longer-lasting bar with improved lather and skin benefits. Without adequate curing, soap may be soft, prone to dissolving quickly, and less effective in cleansing and moisturizing. Properly cured soap typically requires 4 to 6 weeks to reach optimal quality and durability, ensuring consumer satisfaction and product longevity.

Impact of Curing on Customer Satisfaction

Proper curing time in soap making significantly enhances the soap's hardness, lather quality, and skin-friendliness, directly influencing customer satisfaction and repeat purchases. Immediate sale of uncured soap often results in a softer, less stable product prone to faster disintegration and reduced cleansing effectiveness. Ensuring a curing period of 4 to 6 weeks allows excess water to evaporate, concentrating beneficial oils and creating a longer-lasting, more luxurious soap that meets consumer expectations.

Legal and Regulatory Considerations for Selling Uncured Soap

Selling uncured soap may violate health and safety regulations enforced by agencies such as the FDA or EPA, as proper curing ensures complete saponification and reduces residual alkali levels. Regulations often mandate a minimum curing period, typically 4 to 6 weeks, to ensure product safety and prevent skin irritation for consumers. Failure to comply with these legal requirements can result in penalties, product recalls, and liability issues for manufacturers and retailers.

Balancing Production Speed with Product Excellence

Curing time in soap making is essential for ensuring proper saponification and moisture evaporation, which directly impact the soap's hardness, lather quality, and longevity. Immediate sale compromises these factors by delivering a softer, less stable product that may irritate the skin or disintegrate quickly. Balancing production speed with product excellence requires allowing a minimum curing period of 4 to 6 weeks, optimizing both the soap's performance and customer satisfaction.

How Curing Time Affects Fragrance and Texture

Curing time profoundly enhances soap's fragrance and texture by allowing excess water to evaporate, which concentrates aromatic oils and intensifies scent longevity. The gradual saponification process during curing results in a harder, longer-lasting bar with a smooth, creamy lather compared to freshly made soap. Immediate sale prevents these benefits, often yielding a softer soap with muted fragrance that wears down quickly.

Economic Implications: Short-Term Gains vs Long-Term Brand Value

Selling soap immediately after production may generate short-term revenue but often results in lower product quality, leading to customer dissatisfaction and potential brand damage. Extended curing time enhances soap hardness, lather quality, and shelf life, which increases customer trust and repeat purchases, thereby boosting long-term profitability. Balancing immediate cash flow needs with investment in curing processes is essential for sustainable economic growth and brand reputation in the soap making industry.

Effective Inventory Management During the Curing Process

Curing time in soap making, typically ranging from 4 to 6 weeks, is essential for achieving optimal hardness, lather quality, and skin safety, directly impacting product quality and customer satisfaction. Immediate sale of uncured soap risks adverse consumer reactions and decreased product lifespan, leading to increased returns and Inventory obsolescence. Effective inventory management during the curing process involves tracking batches, maintaining ideal storage conditions, and forecasting demand to balance supply with market readiness, minimizing waste and maximizing profitability.

Best Practices for Marketing Cured vs Freshly Made Soap

Cured soap typically requires 4 to 6 weeks to harden, allowing excess water to evaporate and resulting in a longer-lasting, gentler bar preferred by discerning customers. Marketing cured soap should emphasize its superior quality, skin benefits, and durability, targeting consumers seeking premium, natural skincare. Freshly made soap, though visually appealing and available for immediate sale, often lacks the same performance, so marketing should highlight artisanal freshness and unique scents to attract impulse buyers.

Curing Time vs Immediate Sale Infographic

bizdif.com

bizdif.com