Melt and Pour soap making involves melting a pre-made soap base and adding fragrances or colors before pouring it into molds, making it ideal for beginners due to its simplicity. Rebatching requires grating or chopping existing soap, melting it at lower temperatures, then remolding, which helps preserve delicate additives and allows customization for sensitive skin or specific textures. Choosing between melt and pour versus rebatching depends on skill level, desired control over ingredients, and the final soap quality sought.

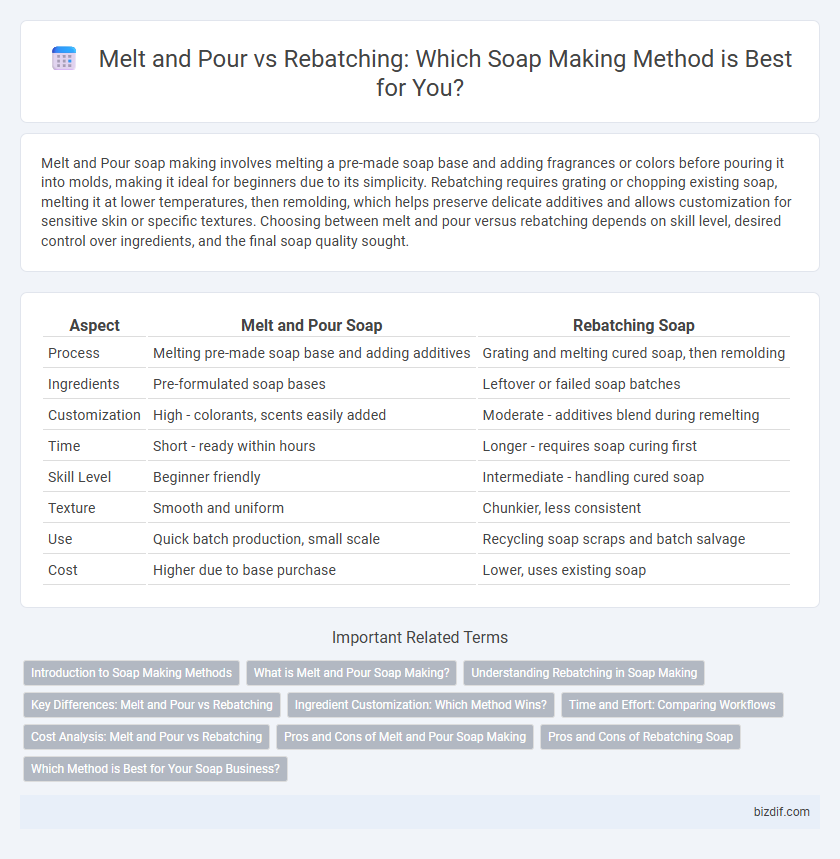

Table of Comparison

| Aspect | Melt and Pour Soap | Rebatching Soap |

|---|---|---|

| Process | Melting pre-made soap base and adding additives | Grating and melting cured soap, then remolding |

| Ingredients | Pre-formulated soap bases | Leftover or failed soap batches |

| Customization | High - colorants, scents easily added | Moderate - additives blend during remelting |

| Time | Short - ready within hours | Longer - requires soap curing first |

| Skill Level | Beginner friendly | Intermediate - handling cured soap |

| Texture | Smooth and uniform | Chunkier, less consistent |

| Use | Quick batch production, small scale | Recycling soap scraps and batch salvage |

| Cost | Higher due to base purchase | Lower, uses existing soap |

Introduction to Soap Making Methods

Melt and pour soap making involves melting pre-made soap bases and adding custom ingredients, offering convenience and quick results ideal for beginners. Rebatching requires grating and melting previously cured soap to incorporate additives, providing better control over texture and ingredients but demanding more time and effort. Both methods bypass the lye handling process, making them safer alternatives to cold process soap making.

What is Melt and Pour Soap Making?

Melt and pour soap making involves melting pre-made soap bases to which colorants, fragrances, and additives are added before pouring into molds for quick solidification. This method eliminates the need for handling lye, making it safe and accessible for beginners in soap crafting. It allows for creative customization while significantly reducing curing time compared to cold process methods.

Understanding Rebatching in Soap Making

Rebatching in soap making involves grating and melting pre-made soap bars to reformulate and customize them with additional ingredients or scents, ensuring a smooth texture and uniform consistency. Unlike melt and pour soap bases, rebatching allows for greater control over the soap's composition and properties, preserving the original soap's qualities while enabling repair of batches with imperfections. This method is ideal for artisans aiming to refine soap texture, adjust ingredients, or salvage failed soap batches without starting from scratch.

Key Differences: Melt and Pour vs Rebatching

Melt and Pour soap involves melting pre-made soap bases and adding colorants or scents before molding, offering ease and speed for beginners and decorative projects. Rebatching entails grating and melting existing soap bars to incorporate additives, preserving natural glycerin and providing greater control over texture and ingredients. The primary difference lies in Melt and Pour's reliance on ready-made bases versus Rebatching's process of reshaping soap, impacting customization and glycerin retention.

Ingredient Customization: Which Method Wins?

Melt and Pour soap offers limited ingredient customization since it uses pre-made soap bases, restricting additions to colorants, fragrances, and exfoliants. Rebatching allows greater flexibility by remelting and blending existing soaps with fresh oils, additives, and botanicals, enabling tailored formulations for specific skin types or preferences. For maximum ingredient customization and control over the final product, rebatching is the superior soap making method.

Time and Effort: Comparing Workflows

Melt and Pour soap crafting significantly reduces time and effort by eliminating the need for saponification, allowing soapmakers to quickly melt pre-made bases and customize with colors, fragrances, and additives. Rebatching, on the other hand, involves grating and melting previously made soaps, requiring more hands-on labor and longer processing times but offers greater control over texture and inclusion of reclaimed soap. Choosing between these workflows depends on prioritizing speed and convenience versus detailed customization and sustainable reuse of soap materials.

Cost Analysis: Melt and Pour vs Rebatching

Melt and Pour soap bases typically incur higher upfront costs due to pre-made ingredients and convenience, while rebatching demands lower initial investment but requires more time and effort for processing leftover soap. Melt and Pour enables faster production cycles, reducing labor expenses, whereas rebatching offers cost savings by recycling scraps, making it ideal for budget-conscious artisans. Balancing material costs, labor input, and batch size is crucial when deciding between Melt and Pour and rebatching methods in soap making.

Pros and Cons of Melt and Pour Soap Making

Melt and pour soap making offers convenience and speed, allowing crafters to avoid dealing with lye, which enhances safety and simplifies the process for beginners. This method enables customization with colorants, fragrances, and additives without compromising soap quality, but it limits the ability to control the core soap chemistry compared to cold process methods. The main drawbacks include higher cost per batch and reduced creative control over ingredients and saponification, making it less suitable for advanced soap makers seeking full formulation flexibility.

Pros and Cons of Rebatching Soap

Rebatching soap allows for greater control over texture and ingredients, making it ideal for correcting imperfections in soap bars. This method preserves the original properties of the soap but requires more labor and time compared to melt and pour techniques. However, rebatching can result in a grainier appearance and less uniformity, posing challenges for commercial consistency.

Which Method is Best for Your Soap Business?

Melt and pour soap offers a quick, beginner-friendly option with ready-made bases, ideal for small batches and customization through additives and fragrances. Rebatching involves grating and remelting previously cured soap to refine texture and incorporate ingredients, providing greater control over final product quality but requiring more time and skill. Soap businesses focusing on efficiency and variety often prefer melt and pour, while those prioritizing artisanal textures and sustainable practices lean toward rebatching.

Melt and Pour vs Rebatching Infographic

bizdif.com

bizdif.com