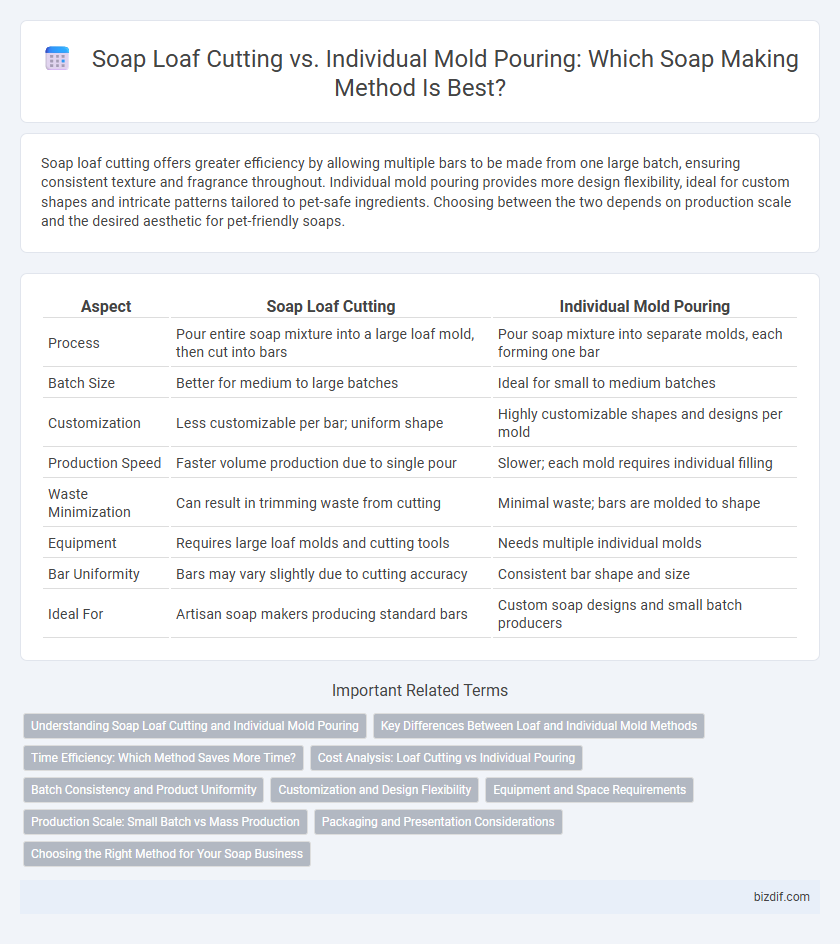

Soap loaf cutting offers greater efficiency by allowing multiple bars to be made from one large batch, ensuring consistent texture and fragrance throughout. Individual mold pouring provides more design flexibility, ideal for custom shapes and intricate patterns tailored to pet-safe ingredients. Choosing between the two depends on production scale and the desired aesthetic for pet-friendly soaps.

Table of Comparison

| Aspect | Soap Loaf Cutting | Individual Mold Pouring |

|---|---|---|

| Process | Pour entire soap mixture into a large loaf mold, then cut into bars | Pour soap mixture into separate molds, each forming one bar |

| Batch Size | Better for medium to large batches | Ideal for small to medium batches |

| Customization | Less customizable per bar; uniform shape | Highly customizable shapes and designs per mold |

| Production Speed | Faster volume production due to single pour | Slower; each mold requires individual filling |

| Waste Minimization | Can result in trimming waste from cutting | Minimal waste; bars are molded to shape |

| Equipment | Requires large loaf molds and cutting tools | Needs multiple individual molds |

| Bar Uniformity | Bars may vary slightly due to cutting accuracy | Consistent bar shape and size |

| Ideal For | Artisan soap makers producing standard bars | Custom soap designs and small batch producers |

Understanding Soap Loaf Cutting and Individual Mold Pouring

Soap loaf cutting involves pouring the soap batter into a large mold, allowing it to harden, and then slicing it into bars, which ensures uniform bar size and efficient curing. Individual mold pouring requires filling separate molds for each bar, resulting in unique shapes and faster unmolding but often demands more space and materials. Choosing between these methods depends on production scale, desired bar consistency, and aesthetics.

Key Differences Between Loaf and Individual Mold Methods

Soap loaf cutting involves pouring a large batch of soap into a single mold and then slicing it into bars after it solidifies, offering efficient production and uniform curing. Individual mold pouring requires filling separate molds for each bar, allowing for intricate designs and varied shapes but generally increasing production time. Key differences include batch size, customization flexibility, and the ease of handling during the curing process.

Time Efficiency: Which Method Saves More Time?

Soap loaf cutting generally saves more time compared to individual mold pouring because it allows a large batch of soap to be poured and cured all at once, reducing repetitive pouring and setting times. Loaves can be sliced into multiple bars quickly after curing, optimizing overall production speed. Individual mold pouring requires filling each mold separately, increasing labor and extending the time needed for soap to harden in each container.

Cost Analysis: Loaf Cutting vs Individual Pouring

Soap loaf cutting generally offers lower production costs due to bulk pouring, reducing mold expenses and labor time compared to individual mold pouring, which requires multiple molds and extended processing. Individual mold pouring tends to increase material costs and time investment but allows for more precise shaping and faster curing, potentially enhancing product value. Choosing between loaf cutting and individual pouring depends on balancing economies of scale with product differentiation and market positioning.

Batch Consistency and Product Uniformity

Cutting soap loaves ensures greater batch consistency as the entire loaf is poured and cured uniformly before being sliced into identical bars, promoting a standardized product texture and hardness. Individual mold pouring can introduce variations in curing and appearance due to small differences in mold shape and heat distribution, potentially affecting product uniformity. For manufacturers prioritizing consistent quality and uniformity across large batches, loaf cutting remains the preferred method.

Customization and Design Flexibility

Soap loaf cutting offers greater customization and design flexibility by allowing soapmakers to create large batches with consistent texture and then slice bars to desired thickness and shape. Individual mold pouring enables detailed, intricate designs and unique shapes in each bar but may limit batch size and uniformity. Choosing between these methods depends on prioritizing large-scale production with adjustable sizing or artisanal, singular soap designs.

Equipment and Space Requirements

Soap loaf cutting requires minimal equipment, mainly a large soap loaf cutter and a sturdy work surface, making it ideal for small-scale production with limited space. Individual mold pouring demands multiple molds and a dedicated area to accommodate mold setup and curing, resulting in a higher spatial footprint and increased equipment complexity. Choosing between these methods depends on production volume, workspace availability, and equipment investment capacity.

Production Scale: Small Batch vs Mass Production

Soap loaf cutting suits small batch production by allowing artisans to create customized soap bars with minimal equipment and flexible batch sizes. Individual mold pouring is ideal for mass production, as it facilitates consistent shapes and faster curing through standardized molds, increasing output efficiency. Choosing between the two depends on the desired production volume, equipment availability, and product uniformity requirements.

Packaging and Presentation Considerations

Soap loaf cutting allows for uniform bar sizes, facilitating consistent packaging and easier labeling, which enhances brand presentation. Individual mold pouring enables more intricate shapes and custom designs, creating a visually appealing product that can attract premium market segments. Both methods influence packaging choices, with loaf cutting favoring bulk wrapping and individual pouring supporting bespoke boxes or clear sleeves to showcase design details.

Choosing the Right Method for Your Soap Business

Choosing the right soap-making method depends on production scale and desired product consistency. Soap loaf cutting offers flexibility for small to medium batches and diverse product shapes, while individual mold pouring ensures uniformity and is ideal for large-scale, consistent bars. Evaluate factors like curing time, aesthetic goals, and equipment investment to optimize efficiency and quality in your soap business.

Soap Loaf Cutting vs Individual Mold Pouring Infographic

bizdif.com

bizdif.com