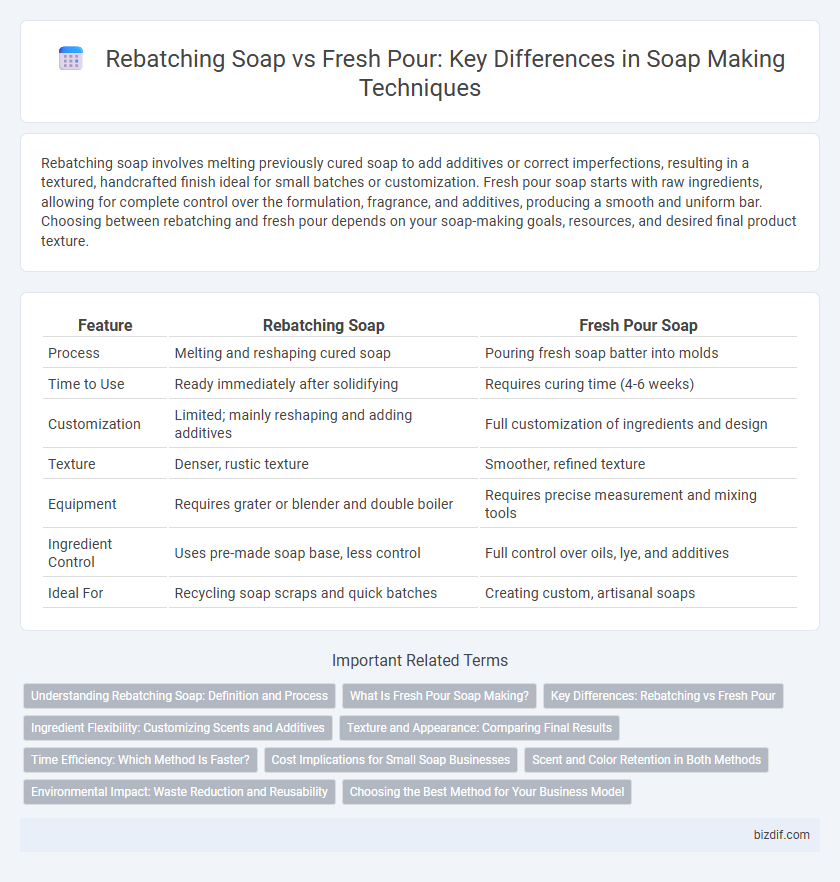

Rebatching soap involves melting previously cured soap to add additives or correct imperfections, resulting in a textured, handcrafted finish ideal for small batches or customization. Fresh pour soap starts with raw ingredients, allowing for complete control over the formulation, fragrance, and additives, producing a smooth and uniform bar. Choosing between rebatching and fresh pour depends on your soap-making goals, resources, and desired final product texture.

Table of Comparison

| Feature | Rebatching Soap | Fresh Pour Soap |

|---|---|---|

| Process | Melting and reshaping cured soap | Pouring fresh soap batter into molds |

| Time to Use | Ready immediately after solidifying | Requires curing time (4-6 weeks) |

| Customization | Limited; mainly reshaping and adding additives | Full customization of ingredients and design |

| Texture | Denser, rustic texture | Smoother, refined texture |

| Equipment | Requires grater or blender and double boiler | Requires precise measurement and mixing tools |

| Ingredient Control | Uses pre-made soap base, less control | Full control over oils, lye, and additives |

| Ideal For | Recycling soap scraps and quick batches | Creating custom, artisanal soaps |

Understanding Rebatching Soap: Definition and Process

Rebatching soap is a soap-making technique where pre-made soap bars are grated, melted, and remolded to create new soap without starting from raw ingredients. This process preserves the original soap's qualities while allowing for customization with added fragrances, colors, or exfoliants. Rebatching is ideal for refining imperfect soap batches or incorporating sensitive additives that might degrade during fresh pour methods.

What Is Fresh Pour Soap Making?

Fresh pour soap making involves melting pre-made soap base, adding custom colors, scents, and additives, then pouring the mixture into molds to harden. This method allows for quick production without the wait time required for cold process soap to cure, enabling immediate use once set. Fresh pour soap maintains the original base's antibacterial properties and is ideal for beginners seeking customization without complex chemical reactions.

Key Differences: Rebatching vs Fresh Pour

Rebatching soap involves melting and reformulating cured soap bars to fix issues or add ingredients, preserving the original soap's characteristics without starting from raw oils. Fresh pour soap, also called cold process soap, requires mixing raw oils with lye and curing for several weeks before use, allowing complete saponification. Key differences include the curing time, process complexity, and flexibility in ingredient customization, with rebatching offering quicker turnaround and repair options while fresh pour enables full control of the soap formulation.

Ingredient Flexibility: Customizing Scents and Additives

Rebatching soap offers greater ingredient flexibility by allowing soapmakers to incorporate scents, colorants, and additives directly into cured base bars, ensuring precise customization without compromising soap stability. Fresh pour soap requires careful formulation beforehand, as ingredients must be fully integrated during the mixing stage, limiting post-pour adjustments. This makes rebatching ideal for experimenting with unique fragrance blends and delicate additives that may degrade in hot processed batches.

Texture and Appearance: Comparing Final Results

Rebatching soap produces a denser, more rustic texture with visible swirls and uneven surfaces, offering a handcrafted aesthetic favored by artisanal soap makers. Fresh pour soap yields a smoother, more uniform appearance with vibrant colors and subtle marbling, ideal for intricate designs and a polished finish. The choice between rebatching and fresh pouring directly impacts the soap's tactile feel and visual appeal, influencing both consumer experience and product presentation.

Time Efficiency: Which Method Is Faster?

Rebatching soap is generally slower because it involves grating, melting, and reshaping pre-made soap, adding extra steps compared to fresh pours. Fresh pour soap is faster as it requires mixing raw ingredients once before pouring them into molds, streamlining the entire process. For soap makers prioritizing time efficiency, fresh pour methods typically save hours in production.

Cost Implications for Small Soap Businesses

Rebatching soap reduces raw material waste by salvaging imperfect batches, making it a cost-effective choice for small soap businesses with limited budgets. Fresh pour soap demands more raw ingredients and time investment, increasing upfront costs but offering greater customization and uniformity that can justify premium pricing. Small businesses must weigh the balance between lower production expenses in rebatching and the potential revenue boost from fresh pour's higher quality appeal.

Scent and Color Retention in Both Methods

Rebatching soap retains scent and color more effectively because it involves melting and reforming already cured soap, which stabilizes fragrance oils and pigments. Fresh pour soap often experiences some scent and color loss due to the intense chemical reactions during saponification. Choosing rebatching helps preserve vibrant hues and stronger aromas, ideal for artisan soap makers prioritizing product consistency.

Environmental Impact: Waste Reduction and Reusability

Rebatching soap significantly reduces waste by salvaging imperfect or leftover soap batches, minimizing the need for new raw materials and lowering overall environmental footprint. Fresh pour soaps require more resources and often generate excess discard due to curing imperfections or unsold products. Emphasizing reusability, rebatching transforms discarded soap into new bars, promoting sustainable practices in soap making through efficient resource use and reduced landfill contribution.

Choosing the Best Method for Your Business Model

Rebatching soap preserves intricate designs and utilizes leftover or imperfect batches, reducing waste and maintaining product consistency, ideal for small-scale or artisanal businesses. Fresh pour soap offers faster production and greater scalability with the ability to experiment with new formulas, better suited for larger operations focused on volume and innovation. Assessing factors like production capacity, resource availability, and target market preferences helps determine the most efficient method to optimize profitability and brand identity.

Rebatching Soap vs Fresh Pour Infographic

bizdif.com

bizdif.com