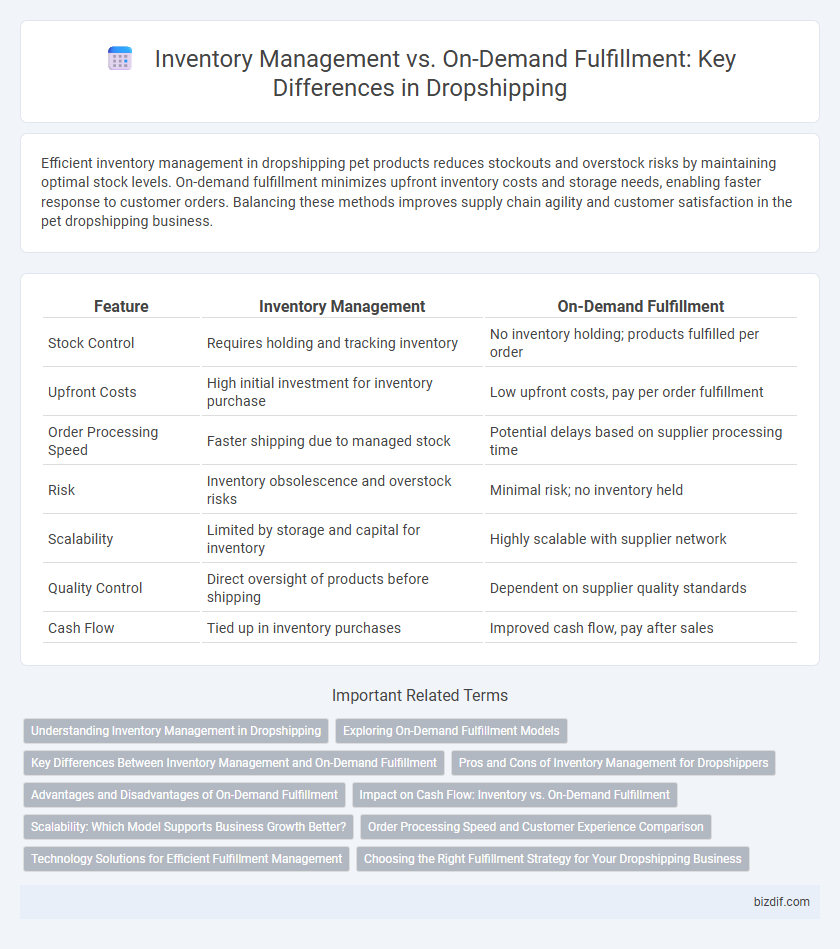

Efficient inventory management in dropshipping pet products reduces stockouts and overstock risks by maintaining optimal stock levels. On-demand fulfillment minimizes upfront inventory costs and storage needs, enabling faster response to customer orders. Balancing these methods improves supply chain agility and customer satisfaction in the pet dropshipping business.

Table of Comparison

| Feature | Inventory Management | On-Demand Fulfillment |

|---|---|---|

| Stock Control | Requires holding and tracking inventory | No inventory holding; products fulfilled per order |

| Upfront Costs | High initial investment for inventory purchase | Low upfront costs, pay per order fulfillment |

| Order Processing Speed | Faster shipping due to managed stock | Potential delays based on supplier processing time |

| Risk | Inventory obsolescence and overstock risks | Minimal risk; no inventory held |

| Scalability | Limited by storage and capital for inventory | Highly scalable with supplier network |

| Quality Control | Direct oversight of products before shipping | Dependent on supplier quality standards |

| Cash Flow | Tied up in inventory purchases | Improved cash flow, pay after sales |

Understanding Inventory Management in Dropshipping

Inventory management in dropshipping involves maintaining accurate tracking of products sourced from suppliers, ensuring stock availability without holding physical goods, which minimizes upfront costs and storage risks. Efficient inventory management systems integrate real-time data synchronization between suppliers and online stores, preventing overselling and stockouts. Mastering these processes enhances customer satisfaction by guaranteeing timely order fulfillment and accurate product availability information.

Exploring On-Demand Fulfillment Models

On-demand fulfillment models in dropshipping eliminate the need for holding inventory by directly shipping products from suppliers to customers, reducing storage costs and minimizing risks of overstock. This approach leverages real-time order processing, enabling businesses to offer a wider variety of products without upfront investment in inventory. By integrating automated systems with supplier databases, on-demand fulfillment optimizes supply chain efficiency and enhances customer satisfaction through faster, accurate deliveries.

Key Differences Between Inventory Management and On-Demand Fulfillment

Inventory management involves maintaining stock levels, tracking product quantities, and forecasting demand to ensure availability, while on-demand fulfillment relies on suppliers to ship products directly to customers without holding inventory. Inventory management offers greater control over product quality and shipping times but requires upfront investment and storage costs, whereas on-demand fulfillment reduces overhead and risk but may result in longer delivery times and less control over inventory status. The key differences lie in inventory ownership, cost structure, and operational control, impacting scalability and customer experience in dropshipping businesses.

Pros and Cons of Inventory Management for Dropshippers

Inventory management in dropshipping offers control over stock levels, enabling faster order processing and better customer satisfaction, but it requires upfront investment and carries the risk of unsold inventory. Maintaining inventory allows for bulk purchasing discounts and improved product quality assurance, yet it demands storage space and increases the complexity of logistics. Dropshippers must weigh the benefits of immediate availability and profit margins against the potential challenges of holding stock and managing supply chain disruptions.

Advantages and Disadvantages of On-Demand Fulfillment

On-demand fulfillment eliminates the need for maintaining large inventory, reducing overhead costs and minimizing the risk of unsold stock, which enhances cash flow efficiency for dropshipping businesses. However, this model often results in longer shipping times and less control over product quality and packaging, potentially affecting customer satisfaction and brand reputation. While on-demand fulfillment offers scalability and flexibility, reliance on third-party suppliers can lead to inventory shortages and inconsistent order processing.

Impact on Cash Flow: Inventory vs. On-Demand Fulfillment

Inventory management requires upfront investment in stock, tying up significant cash flow and increasing risks of overstock or obsolescence. On-demand fulfillment eliminates inventory holding costs by shipping products only after customer orders, improving cash flow flexibility and reducing financial risk. Efficient cash flow management through on-demand fulfillment enables businesses to allocate resources dynamically and scale without large capital commitments.

Scalability: Which Model Supports Business Growth Better?

On-demand fulfillment offers superior scalability by minimizing upfront inventory costs and allowing businesses to quickly adapt to market demand fluctuations without holding stock. Inventory management requires significant capital investment and storage space, potentially limiting rapid expansion due to stock risks and logistical complexities. Choosing on-demand fulfillment enables faster growth and operational flexibility, making it a preferred model for scaling dropshipping businesses efficiently.

Order Processing Speed and Customer Experience Comparison

Inventory management often results in faster order processing since products are pre-stocked and ready for immediate shipment, enhancing customer satisfaction with prompt delivery. On-demand fulfillment relies on suppliers to ship directly to customers, which can introduce delays, potentially impacting the overall customer experience. Efficient inventory control minimizes backorders and stockouts, ensuring consistent order fulfillment speed compared to the variable timelines of on-demand models.

Technology Solutions for Efficient Fulfillment Management

Inventory management leverages technology solutions such as automated stock tracking systems and integrated warehouse management software to maintain optimal stock levels and reduce overstock risks. On-demand fulfillment relies on real-time order processing platforms and API integrations with suppliers to enable seamless, just-in-time product delivery without holding inventory. Advanced technologies like AI-driven demand forecasting and cloud-based fulfillment management systems enhance efficiency by synchronizing inventory data and streamlining supply chain operations.

Choosing the Right Fulfillment Strategy for Your Dropshipping Business

Selecting the right fulfillment strategy for your dropshipping business hinges on balancing inventory management and on-demand fulfillment. Inventory management involves pre-purchasing products to ensure stock availability, reducing shipping times but increasing upfront costs and storage risks. On-demand fulfillment minimizes inventory costs by shipping items only when orders are placed, enhancing flexibility but possibly extending delivery times and relying heavily on supplier reliability.

Inventory Management vs On-Demand Fulfillment Infographic

bizdif.com

bizdif.com