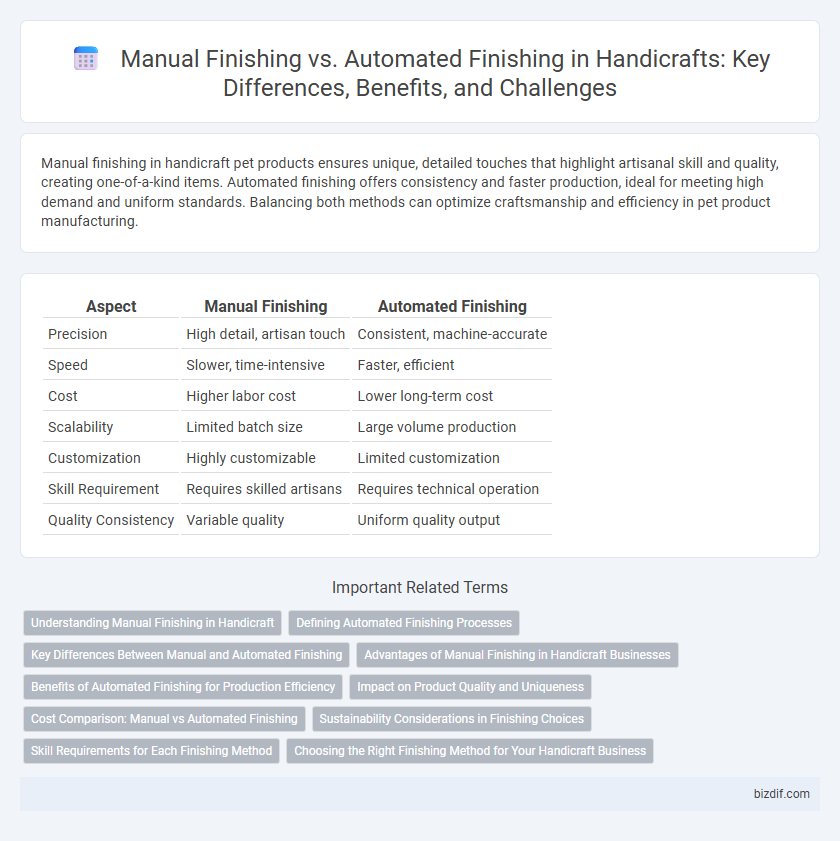

Manual finishing in handicraft pet products ensures unique, detailed touches that highlight artisanal skill and quality, creating one-of-a-kind items. Automated finishing offers consistency and faster production, ideal for meeting high demand and uniform standards. Balancing both methods can optimize craftsmanship and efficiency in pet product manufacturing.

Table of Comparison

| Aspect | Manual Finishing | Automated Finishing |

|---|---|---|

| Precision | High detail, artisan touch | Consistent, machine-accurate |

| Speed | Slower, time-intensive | Faster, efficient |

| Cost | Higher labor cost | Lower long-term cost |

| Scalability | Limited batch size | Large volume production |

| Customization | Highly customizable | Limited customization |

| Skill Requirement | Requires skilled artisans | Requires technical operation |

| Quality Consistency | Variable quality | Uniform quality output |

Understanding Manual Finishing in Handicraft

Manual finishing in handicraft emphasizes intricate detailing and personalized touches that machines cannot replicate, enhancing the uniqueness of each piece. Artisans rely on skilled handwork to achieve precise textures, fine engraving, and delicate embellishments that reflect cultural heritage and craftsmanship. This hands-on approach ensures superior quality control and authenticity, vital for bespoke and high-value handicraft products.

Defining Automated Finishing Processes

Automated finishing processes in handicraft involve the use of machinery and technology to apply surface treatments such as polishing, painting, or coating with precision and consistency. These methods increase production efficiency and ensure uniform quality, reducing human error commonly found in manual finishing. Integration of robotics and computer-controlled systems allows for customizable and scalable finishing solutions tailored to diverse handcrafted products.

Key Differences Between Manual and Automated Finishing

Manual finishing in handicraft involves skilled artisans using hand tools to achieve intricate details and a personalized touch, offering superior customization and craftsmanship quality. Automated finishing utilizes machines for consistent, high-speed production, enhancing efficiency and uniformity across large volumes but often lacks the nuanced detail of manual processes. Key differences include precision control, production scale, and the balance between artisanal authenticity versus industrial consistency.

Advantages of Manual Finishing in Handicraft Businesses

Manual finishing in handicraft businesses ensures superior attention to detail and personalized quality that automated processes often cannot replicate. Skilled artisans can make precise adjustments and intricate touches, enhancing the uniqueness and authenticity of each product. This handcrafted approach also allows for greater flexibility in design customization, meeting specific customer preferences effectively.

Benefits of Automated Finishing for Production Efficiency

Automated finishing significantly enhances production efficiency by accelerating the finishing process and reducing human error, ensuring consistent quality across handicraft products. Integration of robotic systems and precision machinery facilitates high-volume output with minimal labor costs, optimizing resource allocation. This technology also shortens turnaround times, enabling faster market delivery while maintaining intricate design details.

Impact on Product Quality and Uniqueness

Manual finishing in handicrafts enhances product quality by allowing artisans to apply personalized touches and intricate details, resulting in unique, one-of-a-kind items. Automated finishing ensures consistent quality and precision, speeding up production while sometimes compromising the distinctiveness of individual pieces. The choice between manual and automated finishing significantly influences the balance between craftsmanship authenticity and manufacturing efficiency.

Cost Comparison: Manual vs Automated Finishing

Manual finishing in handicrafts typically incurs higher labor costs due to skilled artisans required for intricate detailing, while automated finishing reduces labor expenses but involves significant upfront investment in machinery. Cost efficiency varies depending on production volume; automated finishing becomes more economical for large-scale operations, whereas manual finishing remains cost-effective for small batches and customized products. Maintenance and training expenses for automation also impact total costs, highlighting a balance between personalized craftsmanship and scalability.

Sustainability Considerations in Finishing Choices

Manual finishing in handicrafts promotes sustainability by minimizing energy consumption and reducing waste through precise, small-batch techniques that preserve material integrity. Automated finishing, while boosting production efficiency, often relies on energy-intensive machinery and standardized processes that can generate excess waste and increase the carbon footprint. Choosing manual methods supports eco-friendly practices by enabling artisans to use biodegradable materials and limit harmful chemical use, aligning with sustainable manufacturing goals.

Skill Requirements for Each Finishing Method

Manual finishing demands highly skilled artisans with precision, attention to detail, and dexterity to achieve unique, intricate designs characteristic of handcrafted products. Automated finishing requires proficiency in operating machinery, programming, and maintenance, emphasizing technical expertise over craftsmanship. Skill requirements diverge significantly, with manual finishing centered on artistic skill and automated finishing relying on technical and mechanical knowledge.

Choosing the Right Finishing Method for Your Handicraft Business

Selecting the appropriate finishing method for your handicraft business depends on factors such as product complexity, volume, and desired quality. Manual finishing offers personalized detailing and higher customization, ideal for unique or limited-edition pieces, while automated finishing enhances consistency and efficiency for large-scale production. Balancing craftsmanship authenticity with production demands ensures optimal outcomes and customer satisfaction.

Manual finishing vs Automated finishing Infographic

bizdif.com

bizdif.com