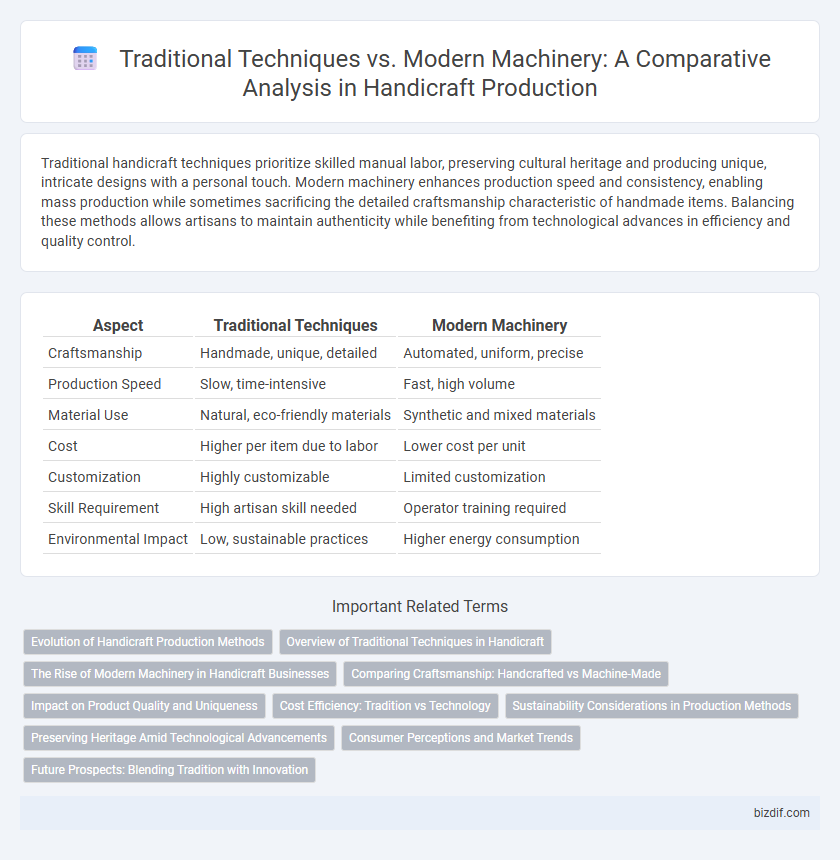

Traditional handicraft techniques prioritize skilled manual labor, preserving cultural heritage and producing unique, intricate designs with a personal touch. Modern machinery enhances production speed and consistency, enabling mass production while sometimes sacrificing the detailed craftsmanship characteristic of handmade items. Balancing these methods allows artisans to maintain authenticity while benefiting from technological advances in efficiency and quality control.

Table of Comparison

| Aspect | Traditional Techniques | Modern Machinery |

|---|---|---|

| Craftsmanship | Handmade, unique, detailed | Automated, uniform, precise |

| Production Speed | Slow, time-intensive | Fast, high volume |

| Material Use | Natural, eco-friendly materials | Synthetic and mixed materials |

| Cost | Higher per item due to labor | Lower cost per unit |

| Customization | Highly customizable | Limited customization |

| Skill Requirement | High artisan skill needed | Operator training required |

| Environmental Impact | Low, sustainable practices | Higher energy consumption |

Evolution of Handicraft Production Methods

Traditional handicraft techniques rely on manual skills and artisanal tools, preserving cultural heritage and intricate craftsmanship. Modern machinery accelerates production, enhances precision, and enables mass customization while maintaining quality standards. The evolution from hand-operated methods to mechanized processes has expanded market reach and innovation in materials, blending tradition with technology in contemporary handicraft production.

Overview of Traditional Techniques in Handicraft

Traditional techniques in handicraft emphasize the use of time-honored skills such as hand carving, weaving, and pottery, which rely on manual dexterity and artisanal knowledge passed down through generations. These methods prioritize unique craftsmanship and intricate detailing, often utilizing natural materials and sustainable practices. The preservation of these techniques supports cultural heritage and provides a distinct, authentic quality that modern machinery cannot replicate.

The Rise of Modern Machinery in Handicraft Businesses

The rise of modern machinery in handicraft businesses has revolutionized production efficiency and consistency, enabling artisans to scale operations without compromising quality. Advanced tools like laser cutters, CNC machines, and automated looms integrate seamlessly with traditional craftsmanship, enhancing intricate designs and reducing manual labor. This fusion of technology and tradition boosts market competitiveness while preserving the cultural essence of handmade goods.

Comparing Craftsmanship: Handcrafted vs Machine-Made

Handcrafted items showcase unique artistry and attention to detail, reflecting the artisan's skill and cultural heritage, which often results in one-of-a-kind products. Machine-made goods offer uniformity and efficiency, enabling mass production with consistent quality but lacking individualized character. The value of handcrafted craftsmanship lies in its authenticity and intricate designs, whereas modern machinery prioritizes speed and scalability.

Impact on Product Quality and Uniqueness

Traditional techniques in handicraft emphasize artisanal skill and cultural heritage, producing unique, high-quality items with intricate details and authentic character. Modern machinery enhances efficiency and consistency, enabling mass production but often at the expense of individuality and the nuanced craftsmanship found in handmade products. The impact on product quality reflects a trade-off between precision and uniqueness, where traditional methods create distinctive art pieces, while modern methods focus on uniformity and scalability.

Cost Efficiency: Tradition vs Technology

Traditional handicraft techniques often involve labor-intensive processes that increase production time and labor costs, making them less cost-efficient compared to modern machinery. Modern machinery streamlines production, reduces human error, and lowers labor expenses, significantly enhancing cost efficiency in large-scale manufacturing. However, traditional methods offer unique value through craftsmanship and cultural heritage that machinery cannot replicate, balancing cost with artistic authenticity.

Sustainability Considerations in Production Methods

Traditional handicraft techniques often prioritize sustainability by utilizing natural, local materials and minimizing waste through meticulous handcrafting processes. Modern machinery can increase production efficiency but may rely on non-renewable resources and generate higher carbon emissions. Sustainable production in handicrafts increasingly integrates eco-friendly machinery and energy-efficient practices to balance heritage preservation with environmental responsibility.

Preserving Heritage Amid Technological Advancements

Traditional handicraft techniques emphasize intricate, manual skills passed down through generations, preserving cultural heritage and unique artistry. Modern machinery increases production efficiency but often risks diluting the authenticity and detailed craftsmanship inherent in handmade products. Balancing these approaches involves integrating selective technological tools while maintaining the core artisanal processes that uphold historical significance and cultural identity.

Consumer Perceptions and Market Trends

Consumers increasingly value the authenticity and uniqueness of handicrafts created through traditional techniques, associating them with cultural heritage and superior craftsmanship. Market trends show a growing niche demand for handmade products despite the efficiency and lower costs offered by modern machinery, reflecting a preference for sustainability and artisanal quality. Brands leveraging traditional methods often capitalize on storytelling and ethical production to differentiate themselves in competitive markets dominated by mass-produced goods.

Future Prospects: Blending Tradition with Innovation

Future prospects in handicraft emphasize integrating traditional techniques with modern machinery to enhance efficiency while preserving cultural authenticity. Advanced tools enable artisans to maintain intricate craftsmanship at scale, fostering innovation without sacrificing heritage. This blend of tradition and technology promises sustainable growth in the global handicraft market, appealing to both contemporary consumers and cultural preservationists.

Traditional Techniques vs Modern Machinery Infographic

bizdif.com

bizdif.com