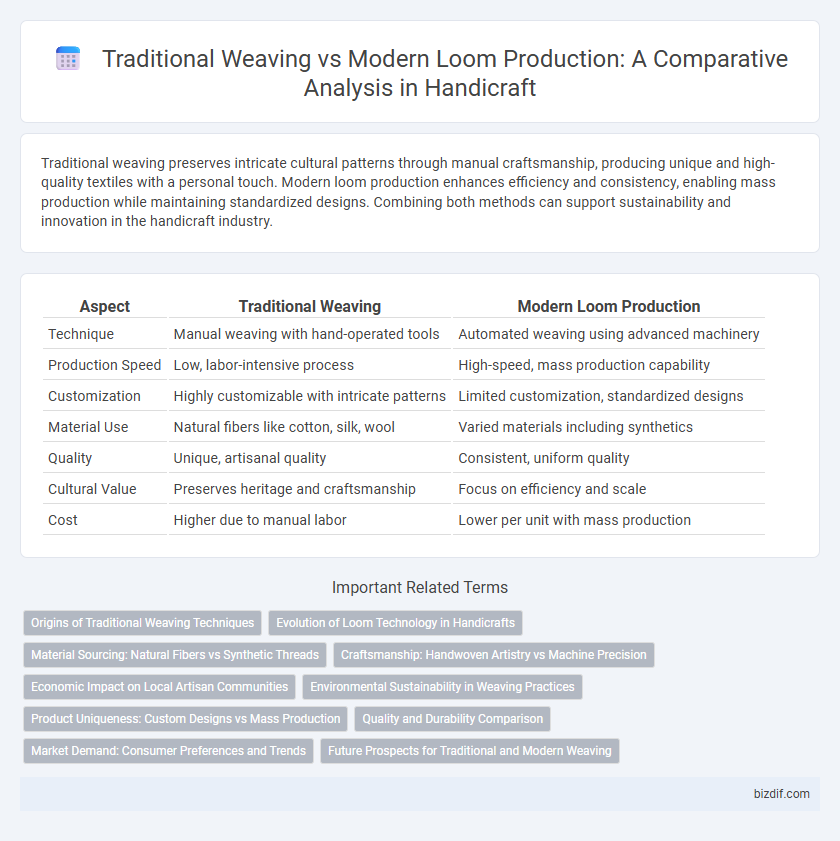

Traditional weaving preserves intricate cultural patterns through manual craftsmanship, producing unique and high-quality textiles with a personal touch. Modern loom production enhances efficiency and consistency, enabling mass production while maintaining standardized designs. Combining both methods can support sustainability and innovation in the handicraft industry.

Table of Comparison

| Aspect | Traditional Weaving | Modern Loom Production |

|---|---|---|

| Technique | Manual weaving with hand-operated tools | Automated weaving using advanced machinery |

| Production Speed | Low, labor-intensive process | High-speed, mass production capability |

| Customization | Highly customizable with intricate patterns | Limited customization, standardized designs |

| Material Use | Natural fibers like cotton, silk, wool | Varied materials including synthetics |

| Quality | Unique, artisanal quality | Consistent, uniform quality |

| Cultural Value | Preserves heritage and craftsmanship | Focus on efficiency and scale |

| Cost | Higher due to manual labor | Lower per unit with mass production |

Origins of Traditional Weaving Techniques

Traditional weaving techniques originate from ancient civilizations, where handloom weaving was integral to cultural identity and daily life. These methods rely on natural fibers such as cotton, wool, and silk, with intricate patterns passed down through generations, reflecting regional artistry. Modern loom production, by contrast, emphasizes mechanization and mass output, often sacrificing the unique heritage and craftsmanship inherent in traditional hand weaving.

Evolution of Loom Technology in Handicrafts

Traditional weaving employs hand-operated looms that emphasize artisanal skill and cultural heritage, producing intricate, unique textile patterns. Modern loom production integrates computerized technology with automated weaving processes, significantly increasing efficiency and consistency in fabric output. The evolution of loom technology in handicrafts reflects a transition from manual craftsmanship to precision-driven industrial production, enhancing scalability while preserving design complexity.

Material Sourcing: Natural Fibers vs Synthetic Threads

Traditional weaving relies heavily on natural fibers such as cotton, wool, silk, and jute, sourced from local, sustainable farms that emphasize eco-friendly practices and organic growth. Modern loom production increasingly incorporates synthetic threads like polyester, nylon, and acrylic, which offer enhanced durability, colorfastness, and cost-efficiency but often depend on nonrenewable petrochemical resources. The choice between natural fibers and synthetic threads significantly impacts the environmental footprint, texture, and market value of woven handicrafts.

Craftsmanship: Handwoven Artistry vs Machine Precision

Traditional weaving showcases intricate handwoven artistry, where skilled artisans create unique patterns with cultural significance through time-honored techniques. Modern loom production relies on machine precision, enabling high-speed manufacturing and uniform fabric quality but often lacks the personalized touch found in handcrafted textiles. The contrast between these methods highlights the value of craftsmanship in preserving heritage versus the efficiency of industrial-scale fabric production.

Economic Impact on Local Artisan Communities

Traditional weaving sustains local artisan communities by preserving cultural heritage and generating income through handcrafted textiles highly valued in niche markets. Modern loom production increases output and reduces costs, but often centralizes manufacturing, limiting economic opportunities for individual artisans. Investing in traditional weaving promotes economic empowerment and cultural preservation, fostering sustainable livelihoods for rural populations.

Environmental Sustainability in Weaving Practices

Traditional weaving utilizes natural fibers and manual techniques that minimize energy consumption and reduce carbon footprint, promoting environmental sustainability. Modern loom production often relies on synthetic materials and electricity-intensive machinery, increasing resource use and environmental impact. Emphasizing eco-friendly dyes, sustainable fiber sourcing, and energy-efficient technologies can enhance the green credentials of both traditional and modern weaving practices.

Product Uniqueness: Custom Designs vs Mass Production

Traditional weaving emphasizes product uniqueness through custom designs crafted by skilled artisans, resulting in intricate patterns and personalized textiles that reflect cultural heritage and individual creativity. Modern loom production focuses on mass production, enabling rapid manufacturing of standardized fabrics with consistent quality, often at lower costs but with limited variation. The contrast lies in handcrafted uniqueness versus uniformity, where traditional weaving offers distinctiveness unmatched by the efficiency of modern looms.

Quality and Durability Comparison

Traditional weaving produces textiles characterized by exceptional quality and durability due to the meticulous handcrafting process using natural fibers and time-tested techniques. Modern loom production enables faster output but often compromises on fabric texture and longevity, relying on synthetic materials and automated precision. The superior resilience and unique craftsmanship of handwoven fabrics make them preferable for long-lasting, high-quality products over mass-produced loom textiles.

Market Demand: Consumer Preferences and Trends

Traditional weaving appeals to niche markets valuing artisanal craftsmanship, cultural heritage, and sustainable production, attracting consumers seeking unique, handcrafted textiles. Modern loom production meets high-volume demand with consistent quality and lower costs, catering to mainstream markets emphasizing affordability and fast fashion trends. Current market trends show growing consumer interest in eco-friendly, ethically made products, driving a resurgence in traditional weaving alongside technologically advanced loom manufacturing.

Future Prospects for Traditional and Modern Weaving

Traditional weaving preserves cultural heritage and supports sustainable practices by utilizing natural fibers and artisanal techniques, appealing to niche markets valuing authenticity and craftsmanship. Modern loom production enhances efficiency and scalability through mechanization and digital technology, meeting global demand for diverse textile products at competitive prices. Future prospects indicate a hybrid approach may emerge, blending traditional artisan skills with advanced machinery to create innovative, sustainable textiles that cater to both heritage appreciation and mass production.

Traditional weaving vs Modern loom production Infographic

bizdif.com

bizdif.com