Traditional jewelry making techniques, such as hand carving, metal casting, and stone setting, emphasize artisanal skill and craftsmanship that create unique, intricate designs. Modern technology integrates computer-aided design (CAD), 3D printing, and laser precision cutting to enhance accuracy, speed, and customization options in jewelry production. The fusion of these methods allows designers to preserve cultural heritage while innovating with new materials and complex patterns.

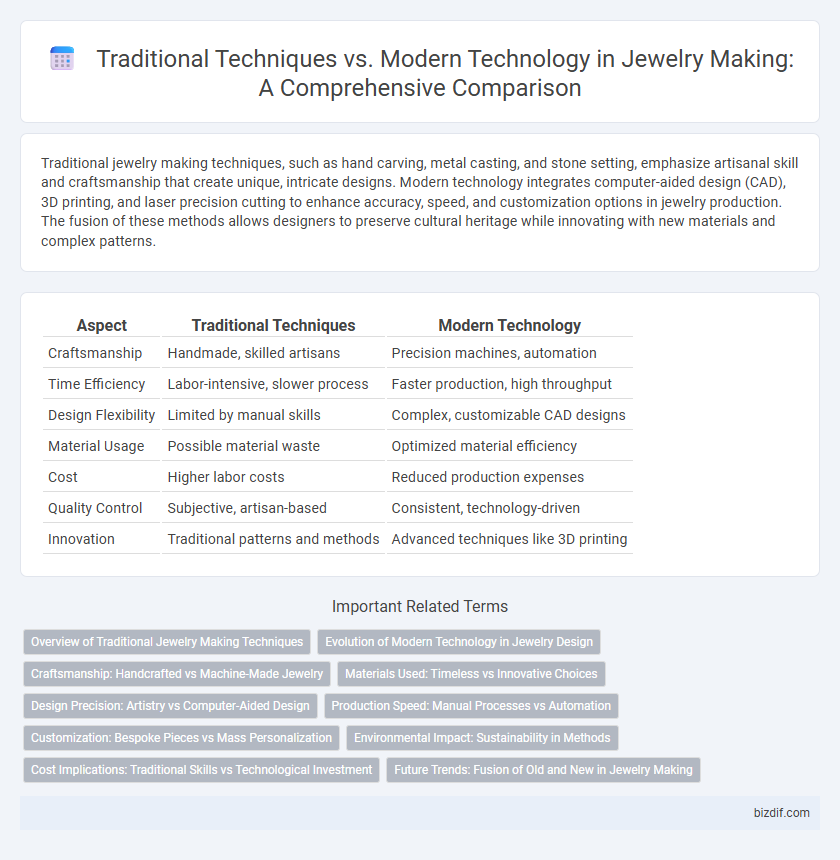

Table of Comparison

| Aspect | Traditional Techniques | Modern Technology |

|---|---|---|

| Craftsmanship | Handmade, skilled artisans | Precision machines, automation |

| Time Efficiency | Labor-intensive, slower process | Faster production, high throughput |

| Design Flexibility | Limited by manual skills | Complex, customizable CAD designs |

| Material Usage | Possible material waste | Optimized material efficiency |

| Cost | Higher labor costs | Reduced production expenses |

| Quality Control | Subjective, artisan-based | Consistent, technology-driven |

| Innovation | Traditional patterns and methods | Advanced techniques like 3D printing |

Overview of Traditional Jewelry Making Techniques

Traditional jewelry making techniques encompass handcrafting methods such as lost-wax casting, filigree, granulation, and repousse, which emphasize artisanal skill and intricate detailing. These techniques often involve manual manipulation of metals and gemstones using simple tools, preserving cultural heritage and timeless design aesthetics. Mastery of traditional methods ensures each piece exhibits unique craftsmanship, durability, and a connection to historical artistry in jewelry making.

Evolution of Modern Technology in Jewelry Design

The evolution of modern technology in jewelry design has revolutionized craftsmanship through tools like 3D printing and computer-aided design (CAD), enabling unprecedented precision and customization. Advanced laser cutting and engraving techniques have enhanced intricate detailing, reducing production time while maintaining quality. These innovations complement traditional techniques, allowing artisans to blend heritage skills with cutting-edge methods for unique, high-quality pieces.

Craftsmanship: Handcrafted vs Machine-Made Jewelry

Handcrafted jewelry showcases the meticulous skill and artistry of experienced artisans, emphasizing unique details and imperfections that reflect individual creativity. Machine-made jewelry benefits from precision and efficiency, allowing for consistent, mass-produced designs with minimal human error. Both approaches influence jewelry quality, with handcrafted pieces prized for their originality and machine-made items valued for affordability and uniformity.

Materials Used: Timeless vs Innovative Choices

Traditional jewelry making relies on timeless materials like gold, silver, and precious gemstones, prized for their durability and classic appeal. Modern technology expands material choices to include innovative options such as titanium, carbon fiber, and lab-grown diamonds, offering enhanced strength, affordability, and sustainability. This fusion of traditional and contemporary materials enables unique designs that balance heritage craftsmanship with cutting-edge advancements.

Design Precision: Artistry vs Computer-Aided Design

Traditional jewelry making techniques emphasize handcrafted artistry, where intricate designs are shaped by skilled artisans, resulting in unique, organic imperfections that add character and value. Modern technology utilizes computer-aided design (CAD) software, enabling precise measurements, complex patterns, and reproducibility beyond manual capabilities. The integration of CAD facilitates faster prototyping and higher accuracy, while preserving artistic creativity through customizable digital modeling.

Production Speed: Manual Processes vs Automation

Manual jewelry-making techniques prioritize craftsmanship, often resulting in intricate details but slower production speed, with artisans dedicating hours to each piece. In contrast, modern technology employs automation such as 3D printing and CNC machining, significantly accelerating production while maintaining consistency and precision. Balancing traditional skills with automated efficiency enables jewelers to meet high demand without compromising artistic quality.

Customization: Bespoke Pieces vs Mass Personalization

Traditional jewelry making techniques emphasize bespoke pieces crafted with meticulous handwork, allowing for unique, one-of-a-kind designs tailored to individual specifications. Modern technology facilitates mass personalization by utilizing digital tools such as 3D printing and CAD software, enabling scalable production while maintaining personalized elements. This fusion enhances customization options, balancing artisanal craftsmanship with efficient, customizable manufacturing processes.

Environmental Impact: Sustainability in Methods

Traditional jewelry-making techniques often rely on handcrafting processes that produce minimal waste and use natural materials, contributing to lower environmental impact. Modern technology introduces methods such as 3D printing and computer-aided design (CAD), which optimize material usage and reduce energy consumption by minimizing errors and excess production. Sustainable practices emerge from integrating both approaches, leveraging precision technology to enhance efficiency while maintaining eco-friendly craftsmanship values.

Cost Implications: Traditional Skills vs Technological Investment

Traditional jewelry making techniques often require extensive manual labor and time, increasing labor costs but minimizing reliance on expensive machinery. In contrast, modern technology demands significant upfront investment in advanced equipment like 3D printers and laser cutters, which can reduce production time and material waste, ultimately lowering per-piece costs in large-scale manufacturing. Cost implications vary widely based on production volume, with traditional skills favoring artisanal, limited runs and technological investments benefiting mass production efficiency.

Future Trends: Fusion of Old and New in Jewelry Making

The fusion of traditional techniques and modern technology in jewelry making is shaping future trends by combining artisanal craftsmanship with innovative tools like 3D printing and laser engraving. This blend allows for intricate, customizable designs that preserve cultural heritage while embracing efficiency and precision. Advances in digital design software and sustainable materials further enhance creativity and environmental responsibility in contemporary jewelry production.

Traditional Techniques vs Modern Technology Infographic

bizdif.com

bizdif.com