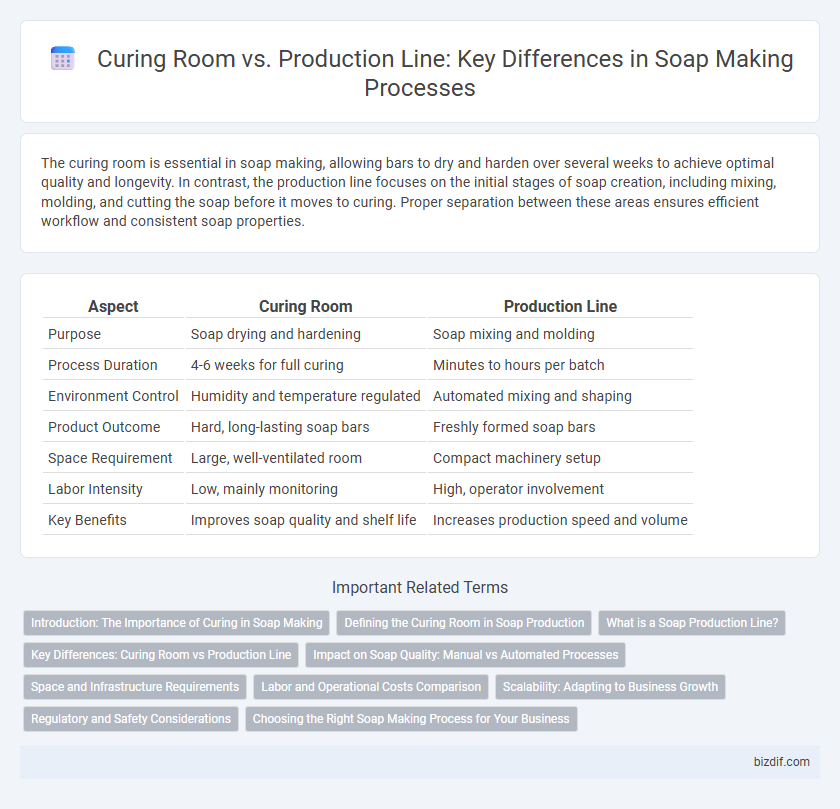

The curing room is essential in soap making, allowing bars to dry and harden over several weeks to achieve optimal quality and longevity. In contrast, the production line focuses on the initial stages of soap creation, including mixing, molding, and cutting the soap before it moves to curing. Proper separation between these areas ensures efficient workflow and consistent soap properties.

Table of Comparison

| Aspect | Curing Room | Production Line |

|---|---|---|

| Purpose | Soap drying and hardening | Soap mixing and molding |

| Process Duration | 4-6 weeks for full curing | Minutes to hours per batch |

| Environment Control | Humidity and temperature regulated | Automated mixing and shaping |

| Product Outcome | Hard, long-lasting soap bars | Freshly formed soap bars |

| Space Requirement | Large, well-ventilated room | Compact machinery setup |

| Labor Intensity | Low, mainly monitoring | High, operator involvement |

| Key Benefits | Improves soap quality and shelf life | Increases production speed and volume |

Introduction: The Importance of Curing in Soap Making

Curing in soap making is essential for completing saponification and reducing moisture content, resulting in a harder, longer-lasting bar with improved lather quality. A dedicated curing room provides optimal conditions such as controlled temperature and humidity, ensuring uniform drying and preventing defects like cracking or mold. In contrast, production lines may prioritize speed, often requiring post-processing storage, which can affect the soap's final quality and consistency.

Defining the Curing Room in Soap Production

The curing room in soap production is a controlled environment where freshly made soap bars undergo drying and hardening processes essential for quality and longevity. Maintaining specific temperature and humidity levels in the curing room ensures proper saponification and moisture evaporation, resulting in a stable, durable product. This specialized area differs from the production line, which focuses on mixing, molding, and initial soap formation before the curing phase begins.

What is a Soap Production Line?

A soap production line is a streamlined manufacturing system designed for the large-scale creation of soap bars, combining processes such as mixing, molding, drying, and packaging. This automated or semi-automated setup increases efficiency, maintains consistent quality, and reduces manual labor compared to traditional batch methods. Unlike the curing room, where soap bars rest and harden over several weeks to develop final texture and longevity, the production line focuses on rapid, precise soap formation and initial drying.

Key Differences: Curing Room vs Production Line

The curing room provides a controlled environment with specific humidity and temperature settings crucial for the soap's drying and hardening process, ensuring product quality and longevity. The production line focuses on the initial stages of soap making, including mixing, molding, and cutting, where raw ingredients are combined and formed into bars. Key differences lie in the curing room's role in final product stability versus the production line's emphasis on shaping and preparing soap for curing.

Impact on Soap Quality: Manual vs Automated Processes

Soap curing rooms provide controlled humidity and temperature, essential for optimal saponification and moisture evaporation, which enhance soap hardness and longevity through manual oversight. Production lines utilize automated processes that ensure consistent ingredient mixing and precise curing times, leading to uniform soap quality and reduced production variability. Manual methods allow for artisan customization and quality checks, while automation increases efficiency and scalability without compromising essential soap properties.

Space and Infrastructure Requirements

A curing room in soap making requires controlled temperature and humidity settings with well-ventilated, dedicated space for optimal soap hardening over several weeks. Production lines demand larger, more flexible infrastructure equipped with automated machinery, storage for raw materials, and efficient workflow design to accommodate continuous soap mixing, molding, and packaging. Proper spatial allocation and specialized environmental controls are critical to maintain product quality and operational efficiency in both curing and production areas.

Labor and Operational Costs Comparison

A curing room requires less direct labor during the soap hardening phase, significantly reducing overall labor costs compared to continuous monitoring on the production line. Operational expenses in a curing room are minimized as energy consumption is mostly limited to maintaining consistent temperature and humidity, whereas production lines incur higher costs from constant machinery operation and frequent quality control adjustments. Choosing a curing room over an extended production line process optimizes workforce allocation, lowers overhead, and enhances cost-efficiency in soap manufacturing.

Scalability: Adapting to Business Growth

A curing room provides controlled environmental conditions that enhance soap quality but limits production volume due to space constraints. Production lines offer scalable automated processes capable of meeting increased demand and accelerating output. Balancing the precision of a curing room with the efficiency of a production line supports seamless business growth in soap manufacturing.

Regulatory and Safety Considerations

Regulatory standards mandate distinct environmental controls for curing rooms and production lines to prevent cross-contamination and ensure product integrity. Curing rooms require strict humidity and temperature regulation alongside isolation protocols to comply with safety codes and maintain soap quality. Production lines must incorporate adequate ventilation, personal protective equipment (PPE), and hygiene practices to meet occupational health regulations and minimize exposure to caustic substances.

Choosing the Right Soap Making Process for Your Business

Selecting the ideal soap making process depends on your business scale and product goals, with the curing room method offering traditional cold process benefits such as enhanced hardness and milder pH levels. In contrast, the production line process excels in efficiency and consistent quality through mechanization, ideal for large-scale operations demanding higher output. Analyzing factors like curing time, production volume, labor costs, and final product characteristics ensures an optimized soap making workflow aligned with market demands.

Curing Room vs Production Line Infographic

bizdif.com

bizdif.com