Lye discounting in pet soap making involves using less lye than the amount required for complete saponification, resulting in a gentler, more moisturizing soap that retains some oils beneficial for a pet's sensitive skin. Zero discounting means using the exact amount of lye needed to fully saponify all the oils, producing a harder, longer-lasting bar but with less residual moisturizing properties. Choosing between lye discounting and zero discounting depends on balancing the pet soap's softness, moisturizing qualities, and durability to meet specific pet skincare needs.

Table of Comparison

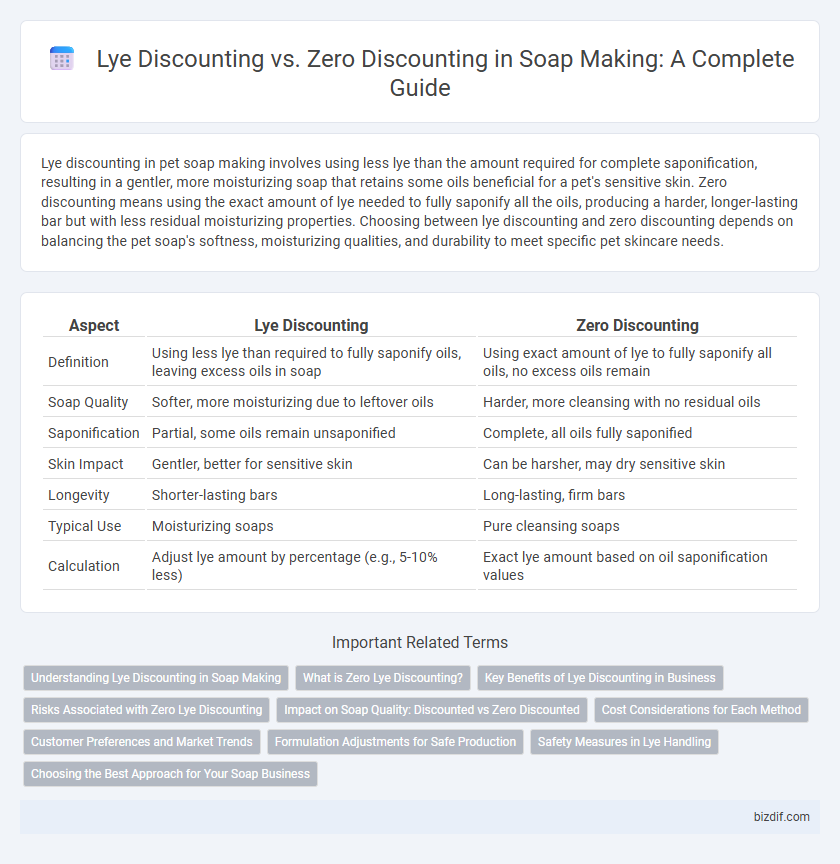

| Aspect | Lye Discounting | Zero Discounting |

|---|---|---|

| Definition | Using less lye than required to fully saponify oils, leaving excess oils in soap | Using exact amount of lye to fully saponify all oils, no excess oils remain |

| Soap Quality | Softer, more moisturizing due to leftover oils | Harder, more cleansing with no residual oils |

| Saponification | Partial, some oils remain unsaponified | Complete, all oils fully saponified |

| Skin Impact | Gentler, better for sensitive skin | Can be harsher, may dry sensitive skin |

| Longevity | Shorter-lasting bars | Long-lasting, firm bars |

| Typical Use | Moisturizing soaps | Pure cleansing soaps |

| Calculation | Adjust lye amount by percentage (e.g., 5-10% less) | Exact lye amount based on oil saponification values |

Understanding Lye Discounting in Soap Making

Lye discounting in soap making involves reducing the amount of lye used to create a more moisturizing and less harsh bar by leaving some oils unsaponified. A typical lye discount ranges from 5% to 10%, which helps enhance the soap's conditioning properties without compromising its cleansing ability. Understanding the precise balance of lye and oils is essential for achieving a safe, effective, and skin-friendly soap.

What is Zero Lye Discounting?

Zero lye discounting in soap making refers to using the exact amount of lye required to saponify all the oils, resulting in no leftover fats or lye. This method produces a fully saponified soap without any excess oils, ensuring a harder, longer-lasting bar. Zero lye discounting requires precise measurements to prevent lye heaviness or soap that is too soft.

Key Benefits of Lye Discounting in Business

Lye discounting in soap making reduces the amount of lye used, resulting in a more moisturizing and skin-friendly product by leaving excess oils uncured. This method enhances customer satisfaction and brand loyalty through gentler formulas that appeal to sensitive skin consumers. Businesses benefit from lye discounting by differentiating their products in a competitive market, reducing potential irritants, and increasing the perceived value of their soaps.

Risks Associated with Zero Lye Discounting

Zero lye discounting in soap making increases the risk of lye-heavy soap, which can cause skin irritation and damage due to unreacted caustic soda. Without the safety buffer provided by lye discounting, precise measurements and thorough mixing are critical to avoid harsh, unsafe soap batches. Soapmakers must carefully balance lye amounts to ensure complete saponification while minimizing potential hazards from excess lye.

Impact on Soap Quality: Discounted vs Zero Discounted

Lye discounting in soap making reduces the amount of lye used, resulting in a softer bar with more moisturizing qualities due to excess oils remaining in the final product. Zero discounting uses the full calculated amount of lye, producing a harder, longer-lasting soap but with less residual oil for skin nourishment. The choice between discounted and zero discounted lye directly influences soap texture, hardness, and skin conditioning properties.

Cost Considerations for Each Method

Lye discounting reduces the amount of lye used in soap making, resulting in a softer, more moisturizing bar but increases costs due to the added excess oils needed for saponification. Zero discounting uses the exact lye amount calculated for complete saponification, maximizing efficiency and minimizing raw material waste, leading to lower overall production costs. The choice between lye discounting and zero discounting depends on balancing desired soap quality with budget constraints, as discounting raises ingredient expenses while zero discounting may yield harsher soap with less conditioning.

Customer Preferences and Market Trends

Customers increasingly favor lye discounting in soap making as it produces milder, more skin-friendly bars that align with the growing demand for natural skincare products. Market trends show that zero discounting, which uses full lye amounts for a harder, longer-lasting soap, appeals mainly to traditional users seeking durability over gentleness. The shift toward lye discounting reflects consumer preference for moisturizing properties and sustainable ingredients in artisanal soap formulations.

Formulation Adjustments for Safe Production

Lye discounting, or superfatting, involves using less lye than calculated, resulting in extra oils that enhance soap moisturizing properties and reduce skin irritation risks. Zero discounting ensures all oils are fully saponified, producing a harder soap with less residual oil but requires precise measurements to prevent excess lye and potential skin sensitivity. Adjusting formulations for safe production requires balancing the intended superfat percentage with lye purity, oil quality, and curing time to optimize soap safety and performance.

Safety Measures in Lye Handling

Lye discounting reduces the amount of lye in soap recipes, lowering the risk of chemical burns and making handling safer by minimizing exposure to caustic substances. Zero discounting uses the exact amount of lye needed for saponification, requiring strict adherence to safety protocols including protective gloves, goggles, and proper ventilation to prevent accidents. Proper storage and careful measuring are essential in both methods to ensure safe soap making practices and prevent hazardous reactions.

Choosing the Best Approach for Your Soap Business

Lye discounting, which involves using less lye than required for complete saponification, results in a superfat soap with extra oils that enhance moisturizing properties and customer appeal. Zero discounting ensures the precise amount of lye converts all oils, producing a harder, longer-lasting bar favored for its consistency and shelf stability. Evaluating factors such as target market preferences, desired soap characteristics, production costs, and ingredient quality helps soap businesses decide between lye discounting for nourishment or zero discounting for durability.

Lye Discounting vs Zero Discounting Infographic

bizdif.com

bizdif.com